Abstract

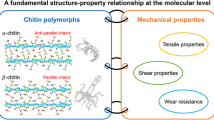

Chitin–protein composite is the structural material of many marine animals including lobster, squid, and sponge. The relationship between mechanical performance and hierarchical nanostructure in those composites attracts extensive research interests. In order to study the molecular mechanism behind, we construct atomistic models of chitin–protein composite and conduct computational tensile tests through molecular dynamics simulations. The effects of water content and chitin fiber length on the stiffness are examined. The result reveals the detrimental effect on the stiffness of chitin–protein composite due to the presence of water molecules. Meanwhile, it is found that the chitin–protein composite becomes stiffer as the embedded chitin fiber is longer. As the tensile deformation proceeds, the stress–strain curve features a saw-tooth appearance, which can be explained by the interlocked zigzag nanostructure between adjacent chitin fibers. These interlocked sites can sacrificially break for energy dissipation when the system undergoes large deformation, leading to an improvement of ductility.

Similar content being viewed by others

References

Tharanathan RN, Kittur FS (2003) Chitin—the undisputed biomolecule of great potential. Crit Rev Food Sci Nutr 43(1):61–87

Ravi Kumar MN (2000) A review of chitin and chitosan applications. React Funct Polym 46(1):1–27

Krajewska B (2004) Application of chitin- and chitosan-based materials for enzyme immobilizations: a review. Enzyme Microb Technol 35(2):126–139

Ehrlich H, Simon P, Carrillo-Cabrera W, Bazhenov VV, Botting JP, Ilan M, Ereskovsky AV, Muricy G, Worch H, Mensch A (2010) Insights into chemistry of biological materials: newly discovered silica-aragonite-chitin biocomposites in demosponges. Chem Mater 22(4):1462–1471

Chen PY, Lin AYM, Lin YS, Seki Y, Stokes AG, Peyras J, Olevsky EA, Meyers MA, McKittrick J (2008) Structure and mechanical properties of selected biological materials. J Mech Behav Biomed Mater 1(3):208–226. doi:10.1016/j.jmbbm.2008.02.003

Vincent JF, Wegst UG (2004) Design and mechanical properties of insect cuticle. Arthropod Struct Dev 33(3):187–199

Miserez A, Li Y, Waite JH, Zok F (2007) Jumbo squid beaks: inspiration for design of robust organic composites. Acta Biomater 3(1):139–149

Politi Y, Priewasser M, Pippel E, Zaslansky P, Hartmann J, Siegel S, Li C, Barth FG, Fratzl P (2012) A spider’s fang: how to design an injection needle using chitin-based composite material. Adv Funct Mater 22(12):2519–2528

Sachs C, Fabritius H, Raabe D (2006) Experimental investigation of the elastic–plastic deformation of mineralized lobster cuticle by digital image correlation. J Struct Biol 155(3):409–425. doi:10.1016/j.jsb.2006.06.004

Romano P, Fabritius H, Raabe D (2007) The exoskeleton of the lobster Homarus americanus as an example of a smart anisotropic biological material. Acta Biomater 3(3):301–309. doi:10.1016/j.actbio.2006.10.003

Raabe D, Sachs C, Romano P (2005) The crustacean exoskeleton as an example of a structurally and mechanically graded biological nanocomposite material. Acta Mater 53(15):4281–4292. doi:10.1016/j.actamat.2005.05.027

Boßelmann F, Romano P, Fabritius H, Raabe D, Epple M (2007) The composition of the exoskeleton of two crustacea: the American lobster Homarus americanus and the edible crab cancer pagurus. Thermochim Acta 463(1–2):65–68. doi:10.1016/j.tca.2007.07.018

Fabritius H-O, Sachs C, Triguero PR, Raabe D (2009) Influence of structural principles on the mechanics of a biological fiber-based composite material with hierarchical organization: The exoskeleton of the Lobster Homarus americanus. Adv Mater 21(4):391–400. doi:10.1002/adma.200801219

Al-Sawalmih A, Li C, Siegel S, Fabritius H, Yi S, Raabe D, Fratzl P, Paris O (2008) Microtexture and chitin/calcite orientation relationship in the mineralized exoskeleton of the American Lobster. Adv Funct Mater 18(20):3307–3314. doi:10.1002/adfm.200800520

Jin K, Feng X, Xu Z (2013) Mechanical properties of chitin–protein interfaces: a molecular dynamics study. BioNanoScience 3(3):312–320. doi:10.1007/s12668-013-0097-2

Nikolov S, Petrov M, Lymperakis L, Friák M, Sachs C, Fabritius H-O, Raabe D, Neugebauer J (2010) Revealing the design principles of high-performance biological composites using Ab initio and multiscale simulations: the example of Lobster cuticle. Adv Mater 22(4):519–526

Yu Z, Xu Z, Lau D (2014) Effect of acidity on chitin–protein interface: a molecular dynamics study. BioNanoScience 4(3):207–215. doi:10.1007/s12668-12014-10138-12665

Yu Z, Lau D (2015) Development of a coarse-grained α-chitin model on the basis of MARITINI forcefield. J Mol Model 21(5):128. doi:10.1007/s00894-015-2670-9

Petrov M, Lymperakis L, Friák M, Neugebauer J (2013) Ab Initio Based conformational study of the crystalline α-chitin. Biopolymers 99(1):22–34

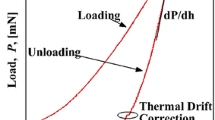

Sachs C, Fabritius H, Raabe D (2006) Hardness and elastic properties of dehydrated cuticle from the lobster Homarus americanus obtained by nanoindentation. J Mater Res 21(08):1987–1995. doi:10.1557/jmr.2006.0241

Sachs C, Fabritius H, Raabe D (2008) Influence of microstructure on deformation anisotropy of mineralized cuticle from the lobster Homarus americanus. J Struct Biol 161(2):120–132. doi:10.1016/j.jsb.2007.09.022

Raabe D, Romano P, Sachs C, Fabritius H, Al-Sawalmih A, Yi SB, Servos G, Hartwig HG (2006) Microstructure and crystallographic texture of the chitin–protein network in the biological composite material of the exoskeleton of the lobster Homarus americanus. Mater Sci Eng A 421(1–2):143–153. doi:10.1016/j.msea.2005.09.115

Ji B, Gao H (2004) Mechanical properties of nanostructure of biological materials. J Mech Phys Solids 52(9):1963–1990

Gao H, Ji B, Jäger IL, Arzt E, Fratzl P (2003) Materials become insensitive to flaws at nanoscale: lessons from nature. Proc Natl Acad Sci 100(10):5597–5600

Ji B, Gao H (2010) Mechanical principles of biological nanocomposites. Annu Rev Mater Res 40:77–100

Dunlop JW, Fratzl P (2013) Multilevel architectures in natural materials. Scripta Mater 68(1):8–12

Jäger I, Fratzl P (2000) Mineralized collagen fibrils: a mechanical model with a staggered arrangement of mineral particles. Biophys J 79(4):1737–1746

Sinko R, Mishra S, Ruiz L, Brandis N, Keten S (2013) Dimensions of biological cellulose nanocrystals maximize fracture strength. ACS Macro Lett 3:64–69

Keten S, Xu Z, Ihle B, Buehler MJ (2010) Nanoconfinement controls stiffness, strength and mechanical toughness of β-sheet crystals in silk. Nat Mater 9(4):359–367

Nova A, Keten S, Pugno NM, Redaelli A, Buehler MJ (2010) Molecular and nanostructural mechanisms of deformation, strength and toughness of spider silk fibrils. Nano Lett 10(7):2626–2634

Chen B, Wu PD, Gao H (2009) A characteristic length for stress transfer in the nanostructure of biological composites. Compos Sci Technol 69(7–8):1160–1164. doi:10.1016/j.compscitech.2009.02.012

Compton OC, Cranford SW, Putz KW, An Z, Brinson LC, Buehler MJ, Nguyen ST (2012) Tuning the mechanical properties of graphene oxide paper and its associated polymer nanocomposites by controlling cooperative intersheet hydrogen bonding. ACS Nano 6(3):2008–2019

Lau D, Büyüköztürk O, Buehler MJ (2012) Characterization of the intrinsic strength between epoxy and silica using a multiscale approach. J Mater Res 27(14):1787–1796

Miserez A, Schneberk T, Sun C, Zok FW, Waite JH (2008) The transition from stiff to compliant materials in squid beaks. Science 319(5871):1816–1819

Sikorski P, Hori R, Wada M (2009) Revisit of α-chitin crystal structure using high resolution X-ray diffraction data. Biomacromolecules 10(5):1100–1105

Humphrey W, Dalke A, Schulten K (1996) VMD: visual molecular dynamics. J Mol Graph 14(1):33–38

Plimpton S (1995) Fast parallel algorithms for short-range molecular dynamics. J Comput Phys 117(1):1–19

Guvench O, Mallajosyula SS, Raman EP, Hatcher E, Vanommeslaeghe K, Foster TJ, Jamison FW, MacKerell AD Jr (2011) CHARMM additive all-atom force field for carbohydrate derivatives and its utility in polysaccharide and carbohydrate-protein modeling. J Chem Theory Comput 7(10):3162–3180

Huang J, MacKerell AD (2013) CHARMM36 all-atom additive protein force field: Validation based on comparison to NMR data. J Comput Chem 34(25):2135–2145

Beckham GT, Crowley MF (2011) Examination of the α-chitin structure and decrystallization thermodynamics at the nanoscale. J Phys Chem B 115(15):4516–4522

Mori T, Tanaka K (1973) Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Metall 21(5):571–574

Torquato S (1998) Effective stiffness tensor of composite media: II. Applications to isotropic dispersions. J Mech Phys Solids 46(8):1411–1440

Nikolov S, Fabritius H, Petrov M, Friák M, Lymperakis L, Sachs C, Raabe D, Neugebauer J (2011) Robustness and optimal use of design principles of arthropod exoskeletons studied by ab initio-based multiscale simulations. J Mech Behav Biomed Mater 4(2):129–145

Miserez A, Rubin D, Waite JH (2010) Cross-linking chemistry of squid beak. J Biol Chem 285(49):38115–38124

Smith BL, Schäffer TE, Viani M, Thompson JB, Frederick NA, Kindt J, Belcher A, Stucky GD, Morse DE, Hansma PK (1999) Molecular mechanistic origin of the toughness of natural adhesives, fibres and composites. Nature 399(6738):761–763

Gebeshuber IC, Kindt JH, Thompson JB, Del Amo Y, Stachelberger H, Brzezinski MA, Stucky GD, Morse DE, Hansma PK (2003) Atomic force microscopy study of living diatoms in ambient conditions. J Microsc 212(3):292–299. doi:10.1111/j.1365-2818.2003.01275.x

Dugdale TM, Dagastine R, Chiovitti A, Mulvaney P, Wetherbee R (2005) Single adhesive nanofibers from a live diatom have the signature fingerprint of modular proteins. Biophys J 89(6):4252–4260. doi:10.1529/biophysj.105.062489

Sarkar A, Caamano S, Fernandez JM (2007) The mechanical fingerprint of a parallel polyprotein dimer. Biophys J 92(4):L36–L38. doi:10.1529/biophysj.106.097741

Acknowledgements

The authors are grateful to the support from Croucher Foundation through the Start-up Allowance for Croucher Scholars with the Grant No. 9500012, and the support from the Research Grants Council (RGC) in Hong Kong through the Early Career Scheme (ECS) with the Grant No. 139113.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, Z., Lau, D. Molecular dynamics study on stiffness and ductility in chitin–protein composite. J Mater Sci 50, 7149–7157 (2015). https://doi.org/10.1007/s10853-015-9271-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9271-y