Abstract

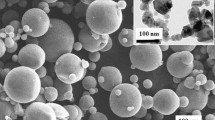

Silicon carbide is used for a variety of applications, however, sintering still remains a challenge due to the high temperature and pressure required as well as the need for sintering aids. The use of preceramic polymers as binder is a promising technique for pressureless low-temperature sintering of SiC without sintering aids. However, the mechanical and thermophysical properties as well as the microstructure of bodies sintered through this technique has not been extensively documented. One of the main polymers which has gained attention in the past few years as a SiC preceramic is allylhydridopolycarbosilane (AHPCS). Here, using AHPCS as binder, silicon carbide pellets were sintered at temperatures as low as 930 °C, and the microstructural, mechanical, and thermophysical property characterization is presented. Compared to conventionally sintered SiC, the material shows similar fracture toughness, lower hardness, strength, and thermal conductivity. The observed properties are explained as a result of residual porosity combined with amorphous SiC at the grain boundaries.

Similar content being viewed by others

References

Yajima S, Shishido T, Kayano H, Okamura K, Omori M, Hayashi J (1976) SiC sintered bodies with 3-dimensional polycarbosilane as binder. Nature 264(5583):238–239

Dressler W, Riedel R (1997) Progress in silicon-based non-oxide structural ceramics. Int J Refract Met Hard Mater 15(1–3):13–47

Snead LL, Nozawa T, Katoh Y, Byun TS, Kondo S, Petti DA (2007) Handbook of SiC properties for fuel performance modeling. J Nucl Mater 371(1–3):329–377. doi:10.1016/j.jnucmat.2007.05.016

Renz R, Seifert G, Krenkel W (2012) Integration of CMC brake disks in automotive brake systems. Int J Appl Ceram Technol 9(4):712–724. doi:10.1111/j.1744-7402.2012.02812.x

Ledoux MJ, Pham-Huu C (2001) Silicon carbide—a novel catalyst support for heterogeneous catalysis. Cattech 5(4):226–246. doi:10.1023/A:1014092930183

Yvon P, Carre F (2009) Structural materials challenges for advanced reactor systems. J Nucl Mater 385(2):217–222. doi:10.1016/j.jnucmat.2008.11.026

Lee JK, Park JG, Lee EG, Seo DS, Hwang Y (2002) Effect of starting phase on microstructure and fracture toughness of hot-pressed silicon carbide. Mater Lett 57(1):203–208. doi:10.1016/S0167-577x(02)00765-6

Bouillon E, Mocaer D, Villeneuve JF, Pailler R, Naslain R, Monthioux M, Oberlin A, Guimon C, Pfister G (1991) Composition microstructure property relationships in ceramic monofilaments resulting from the pyrolysis of a polycarbosilane precursor at 800 to 1400°C. J Mater Sci 26(6):1517–1530. doi:10.1007/BF00544661

Hasegawa Y, Iimura M, Yajima S (1980) Synthesis of continuous silicon-carbide fiber: part 2. Conversion of polycarbosilane fiber into silicon-carbide fibers. J Mater Sci 15(3):720–728. doi:10.1007/BF00551739

Hasegawa Y, Okamura K (1983) Synthesis of continuous silicon-carbide fiber: part 3. Pyrolysis process of polycarbosilane and structure of the products. J Mater Sci 18(12):3633–3648. doi:10.1007/BF00540736

Maddocks AR, Cassidy DJ, Jones AS, Harris AT (2009) Synthesis of nanoporous silicon carbide via the preceramic polymer route. Mater Chem Phys 113(2–3):861–867. doi:10.1016/j.matchemphys.2008.08.064

Maddocks AR, Hook JM, Stender H, Harris AT (2008) Heterogeneously catalysed crosslinking of polycarbosilane with divinylbenzene. J Mater Sci 43(8):2666–2674. doi:10.1007/s10853-008-2488-2

Bernardo E, Ponsot I, Colombo P, Grasso S, Porwal H, Reece MJ (2014) Polymer-derived SiC ceramics from polycarbosilane/boron mixtures densified by SPS. Ceram Int 40(9):14493–14500. doi:10.1016/j.ceramint.2014.07.008

Kotani M, Inoue T, Kohyama A, Okamura K, Katoh Y (2002) Consolidation of polymer-derived SiC matrix composites: processing and microstructure. Compos Sci Technol 62(16):2179–2188. doi:10.1016/S0266-3538(02)00151-3

Kotani M, Nishiyabu K, Matsuzaki S, Tanaka S (2011) Processing of polymer-derived porous SiC body using allylhydridopolycarbosilane (AHPCS) and PMMA microbeads. J Ceram Soc Jpn 119(1391):563–569. doi:10.2109/jcersj2.119.563

Berbon M, Calabrese M (2002) Effect of 1600°C heat treatment on C/SiC composites fabricated by polymer infiltration and pyrolysis with allylhydridopolycarbosilane. J Am Ceram Soc 85(7):1891–1893

Kotani M, Katoh Y, Kohyama A, Narisawa M (2003) Fabrication and oxidation-resistance property of allylhydridopolycarbosilane-derived SiC/SiC composites. J Ceram Soc Jpn 111(5):300–307

Sarma KH, Fourcade J, Lee SG, Solomon AA (2006) New processing methods to produce silicon carbide and beryllium oxide inert matrix and enhanced thermal conductivity oxide fuels. J Nucl Mater 352(1–3):324–333. doi:10.1016/j.jnucmat.2006.02.090

Shih CH, Tulenko JS, Baney RH (2011) Low-temperature synthesis of silicon carbide inert matrix fuel through a polymer precursor route. J Nucl Mater 409(3):199–206. doi:10.1016/j.jnucmat.2010.12.027

Puerta AR, Remsen EE, Bradley MG, Sherwood W, Sneddon LG (2003) Synthesis and ceramic conversion reactions of 9-BBN-modified allylhydridopolycarbosilane: a new single-source precursor to boron-modified silicon carbide. Chem Mater 15(2):478–485. doi:10.1021/Cm020697i

Sreeja R, Swaminathan B, Painuly A, Sebastian TV, Packirisamy S (2010) Allylhydridopolycarbosilane (AHPCS) as matrix resin for C/SiC ceramic matrix composites. Mater Sci Eng B 168(1–3):204–207. doi:10.1016/j.mseb.2009.12.033

Mcgeary RK (1961) Mechanical packing of spherical particles. J Am Ceram Soc 44(10):513–522

Knippenberg W (1963) The growth of SiC by recrystallization and sublimation. Growth Phenom Silicon Carbide 18(3):244–266

Krishna P, Marshall R, Ryan C (1971) The discovery of a 2H-3C solid state transformation in silicon carbide single crystals. J Cryst Growth 8(1):129–131

Harris GL (1995) Properties of silicon carbide, vol 13. IEE, London

Moraes KV, Interrante LV (2003) Processing, fracture toughness, and vickers hardness of allylhyd ridopolycarbosilane-derived silicon carbide. J Am Ceram Soc 86(2):342–346

Chantikul P, Anstis GR, Lawn BR, Marshall DB (1981) A critical-evaluation of indentation techniques for measuring fracture-toughness: part 2. Strength method. J Am Ceram Soc 64(9):539–543

Wachtman JB, Capps W, Mandel J (1972) Biaxial flexure tests of ceramic substrates. J Mater 7(2):188–194

Clark LM, Taylor RE (1975) Radiation loss in flash method for thermal-diffusivity. J Appl Phys 46(2):714–719

Maglic KD, Milosevic ND (2004) Thermal diffusivity measurements of thermographite. Int J Thermophys 25(1):237–247. doi:10.1023/B:IJOT.0000022337.88761.a4

Starfire® Systems Inc StarPCS SMP-10

Dire S, Tagliazucca V, Salvadori L, Soraru GD (2011) Preparation of dense and porous silicon oxycarbide submicrometer-sized spheres using a modified stober process. J Am Ceram Soc 94(11):3819–3824

Low I-M (2013) MAX phases and ultra-high temperature ceramics for extreme environments. IGI Global, Hershey

Ma Y, Wang S, Chen ZH (2010) Raman spectroscopy studies of the high-temperature evolution of the free carbon phase in polycarbosilane derived SiC ceramics. Ceram Int 36(8):2455–2459. doi:10.1016/j.ceramint.2010.08.003

Ferrari AC, Robertson J (2000) Interpretation of Raman spectra of disordered and amorphous carbon. Phys Rev B 61(20):14095

Baraton MI, ElShall MS (1995) Synthesis and characterization of nanoscale metal oxides and carbides. 2. Micro-Raman and FT-IR surface studies of a silicon carbide powder. Nanostruct Mater 6(1–4):301–304. doi:10.1016/0965-9773(95)00057-7

Trassl S, Motz G, Rossler E, Ziegler G (2002) Characterization of the free-carbon phase in precursor-derived Si-C-N ceramics: I, spectroscopic methods. J Am Ceram Soc 85(1):239–244

Jang BK, Kim SY, Han IS, Seo DW, Hong KS, Woo SK, Sakka Y (2010) Influence of uni and bi-modal SiC composition on mechanical properties and microstructure of reaction-bonded SiC ceramics. J Ceram Soc Jpn 118(1383):1028–1031

She JH, Deng ZY, Daniel-Doni J, Ohji T (2002) Oxidation bonding of porous silicon carbide ceramics. J Mater Sci 37(17):3615–3622. doi:10.1023/A:1016596805717

Akiyoshi M (2009) Thermal diffusivity of ceramics at the neutron irradiation temperature estimated from post-irradiation measurements at 123-413 K. J Nucl Mater 386–88:303–306. doi:10.1016/j.jnucmat.2008.12.118

Lee SG, Fourcade J, Latta R, Solomon AA (2008) Polymer impregnation and pyrolysis process development for improving thermal conductivity of SiCp/SiC-PIP matrix fabrication. Fusion Eng Des 83(5–6):713–719. doi:10.1016/j.fusengdes.2008.04.008

Senor DJ, Youngblood GE, Greenwood LR, Archer DV, Alexander DL, Chen MC, Newsome GA (2003) Defect structure and evolution in silicon carbide irradiated to 1 dpa-SiC at 1100°C. J Nucl Mater 317(2–3):145–159. doi:10.1016/S0022-3115(03)00077-1

Bruls RJ, Hintzen HT, Metselaar R (2005) A new estimation method for the intrinsic thermal conductivity of nonmetallic compounds—a case study for MgSiN2, AlN, and beta-Si3N4 ceramics. J Eur Ceram Soc 25(6):767–779. doi:10.1016/j.jeurceramsoc.2004.05.003

Shih CH, Tulenko JS, Baney RH (2011) The effect of mixing methods and polymer infiltration and pyrolysis (PIP) cycles on the densification of silicon carbide inert matrix fuel through a polymer precursor route. J Nucl Mater 419(1–3):63–71. doi:10.1016/j.jnucmat.2011.07.020

Acknowledgements

The authors gratefully acknowledge Dr. John Mecholsky, Dr. Anthony Brennan, Dr. Ronald Baney, and Dr. Gerald Bourne for allowing us the use of equipment necessary to carry out most of the measurements. We also thank Dr. Chunghao Shih for his help on the experimental part of this work. Finally, we recognize the Major Analytical Instrumentation Center at the University of Florida for providing access to the SEM and the Nano Research Facility at the University of Florida for providing access to the microRaman spectrometer. This material is based upon the work supported under a Department of Energy Nuclear Energy University Programs Graduate Fellowship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mehr, M., Moore, D.T., Esquivel-Elizondo, J.R. et al. Mechanical and thermal properties of low temperature sintered silicon carbide using a preceramic polymer as binder. J Mater Sci 50, 7000–7009 (2015). https://doi.org/10.1007/s10853-015-9252-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9252-1