Abstract

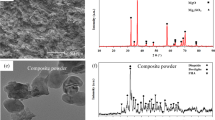

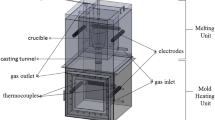

Magnesium has attracted notability as a biodegradable material. Several studies have reported that magnesium containing calcium (Ca) had biosafety with higher mechanical properties. However, Mg–1Ca alloy showed non-uniform corrosion properties with bone. In this study, various Ca amounts were added to commercial magnesium alloy AZ31B to improve the corrosion resistance and microstructure. AZ31B billet was prepared by casting without Ca. The AZ31B alloy ingots were melted and recasted with Ca quantities at 1.5 and 2.5 wt%. Extrusion ingots were pressed out to a plate with thickness of 5 mm and width of 80 mm at 1650 °C. The microstructure of the alloy was observed by optical microscopy and SEM. The composition of the alloy was analyzed by EDX. To examine the corrosion properties, potentiodynamic polarization was used to measure the corrosion potential and current density. Osteoblast cells MC3T3-E1 were incubated with the samples to allow cell attachment and MTT assay. The microstructure of alloys was homogeneously distributed over the surface and observed phase boundary. Preliminary elemental analysis suggested that the second phases were Al2Ca and Mg2Ca. Grain refinement by extrude casting was obtained for AZ31B–xCa. The corrosion resistant of AZ31B–xCa by current density was greater than the AZ31B because the standard electrode potential of Mg phase was lower than Mg2Ca. In vitro studies showed that the reduction of corrosion resistance and mechanical ability of the magnesium alloy after addition of Ca were not correlated with bioactivity. In particular, AZ31B–1.5Ca had higher formation of biomimetic substances and lower cytotoxicity, even though it had more vulnerable mechanical properties than AZ31B. Based on this result, the effect of Ca ion on commercial alloy AZ31B, mechanical properties, and bioactivity as biodegradable implant were discussed.

Similar content being viewed by others

References

Akiyama SUH, Sakamoto M, Hirai H, Kitahara A (2000) Development of noncombustible magnesium alloys. Mater Jpn 39:72–74

Chen SY, Chang GW, Huang YD, Liu SY (2013) Effects of melt temperature on as-cast structure and mechanical properties of AZ31B magnesium alloy. Trans Nonferr Met Soc China 23:1602–1609

Dahle AK, Lee YC, Nave MD, Schaffer PL, StJohn DH (2001) Development of the as-cast microstructure in magnesium–aluminium alloys. J Light Met 1:61–72

Du H, Wei Z, Liu X, Zhang E (2011) Effects of Zn on the microstructure, mechanical property and bio-corrosion property of Mg–3Ca alloys for biomedical application. Mater Chem Phys 125:568–575

Gu XN, Zheng YF (2010) A review on magnesium alloys as biodegradable materials. Front Mater Sci China 4:111–115

Gunde P, Hänzi AC, Sologubenko AS, Uggowitzer PJ (2011) High-strength magnesium alloys for degradable implant applications. Mater Sci Eng A 528:1047–1054

Ilich JZ, Kerstetter JE (2000) Nutrition in bone health revisited: a story beyond calcium. J Am Coll Nutr 19:715–737

Verbrugge J (1937) Lutilisation du magnésium dans le traitement chirurgical des fractures. Bull Mém Soc Nat Cir 59:813–823

Kim Y, Park I, Lee S, Lee M (2013) Biodegradation and cytotoxic properties of pulse anodized Mg alloys. Met Mater Int 19:353–360

Lee YC, Dahle AK, StJohn DH (2000) The role of solute in grain refinement of magnesium. Metall Mater Trans A 31:2895–2906

Li H, He Y, Zeng ZD (2006) A neural network model for prediction on mechanical properties of QA110-5-5 aluminum bronze after aging. Heat Treat Met 31:28–30

Li L, Gao J, Wang Y (2004) Evaluation of cyto-toxicity and corrosion behavior of alkali-heat-treated magnesium in simulated body fluid. Surf Coat Technol 185:92–98

Li Z, Gu X, Lou S, Zheng Y (2008) The development of binary Mg–Ca alloys for use as biodegradable materials within bone. Biomaterials 29:1329–1344

Liu C, Yang H, Wan P, Wang K, Tan L, Yang K (2014) Study on biodegradation of the second phase Mg17Al12 in Mg–Al–Zn Alloys: in vitro experiment and thermodynamic calculation. Mater Sci Eng C 35:1–7

Nguyen QB, Gupta M (2009) Microstructure and mechanical characteristics of AZ31B/Al2O3 nanocomposite with addition of Ca. J Compos Mater 43:5–17

Ozturk K, Zhong Y, Liu Z-K, Luo A (2003) Creep resistant Mg–Al–Ca alloys: computational thermodynamics and experimental investigation. JOM 55:40–44

Ozturk K, Zhong Y, Luo AA, Liu Z-K (2003) Creep resistant Mg–Al–Ca alloys: computational thermodynamics and experimental investigation. JOM 55:40–44

Park JP, Kim MG, Yoon US, Kim WJ (2009) Microstructures and mechanical properties of Mg–Al–Zn–Ca alloys fabricated by high frequency electromagnetic casting method. J Mater Sci 44:47–54. doi:10.1007/s10853-008-3130-z

Qudong W, Wenzhou C, Xiaoqin Z, Yizhen L, Wenjiang D, Yanping Z, Xiaoping X, Mabuchi M (2001) Effects of Ca addition on the microstructure and mechanical properties of AZ91magnesium alloy. J Mater Sci 36:3035–3040. doi:10.1023/A:1017927109291

Raj R, Ashby MF (1975) Intergranular fracture at elevated temperature. Acta Metall 23:653–666

Serre CM, Papillard M, Chavassieux P, Voegel JC, Boivin G (1998) Influence of magnesium substitution on a collagen–apatite biomaterial on the production of a calcifying matrix by human osteoblasts. J Biomed Mater Res 42:626–633

Shreir LL (1979) Corrosion. Newnes-Butlerworths, London, p 89

Staiger MP, Pietak AM, Huadmai J, Dias G (2006) Magnesium and its alloys as orthopedic biomaterials: a review. Biomaterials 27:1728–1734

Witte F, Fischer J, Nellesen J, Vogt C, Vogt J, Donath T, Beckmann F (2010) In vivo corrosion and corrosion protection of magnesium alloy LAE442. Acta Biomater 6:1792–1799

Zhang E, Yang L (2008) Microstructure, mechanical properties and bio-corrosion properties of Mg–Zn–Mn–Ca alloy for biomedical application. Mater Sci Eng A 497:111–118

Zhang E, Yang L, Xu J, Chen H (2010) Microstructure, mechanical properties and bio-corrosion properties of Mg–Si(–Ca, Zn) alloy for biomedical application. Acta Biomater 6:1756–1762

Zhang Z, Couture A, Luo A (1998) An investigation of the properties of Mg–Zn–Al alloys. Scr Mater 39:45–53

Acknowledgements

This work was financially supported by the ‘National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIP) (Nos. 2011-0028709 and 2014R1A4A1005309),’ and Regional Strategic Industry project (2013-R0002274).

Author information

Authors and Affiliations

Corresponding author

Additional information

Il Song Park have contributed equally to this work and is considered as joint first author.

Rights and permissions

About this article

Cite this article

Kim, Y.K., Park, I.S., Lee, K.B. et al. Characterization and biocompatibility of a calcium-containing AZ31B alloy as a biodegradable material. J Mater Sci 50, 4672–4682 (2015). https://doi.org/10.1007/s10853-015-9018-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9018-9