Abstract

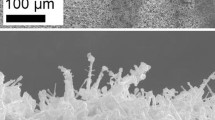

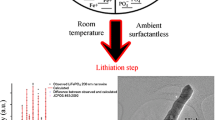

One-dimensional (1D) nanostructures, often referred to as nanowires, have attracted considerable attention due to their unique mechanical, chemical, and electrical properties. Although numerous novel technological applications are being proposed for these structures, many of the processes used to synthesize these materials involve a vapor phase and require high temperatures and long growth times. Potentially faster methods requiring templates, such as anodized aluminum oxide, involve multiple fabrication steps, which would add significantly to the cost of the final material and may preclude their widespread use. In the present study, it is shown that template-free electrodeposition from an alkaline solution can produce arrays of Sn nanoneedles directly onto Cu foil substrates. This electrodeposition process occurs at 55 °C; it is proposed that the nanoneedles grow via a catalyst-mediated mechanism. In such a process, the growth is controlled at the substrate/nanostructure interface rather than resulting from random plating-induced defects such as dendrites or aging defects such as tin whiskers. There are multiple potential applications for 1D Sn nanostructures—these include anodes in lithium-ion and magnesium-ion batteries and as thermal interface materials. To test this potential, type 2032 lithium-ion battery button cells were fabricated using the electrodeposited Sn. These cells showed initial capacities as high as 850 mAh/g and cycling stability for over 200 cycles.

Similar content being viewed by others

References

Spencer M (2012) Gas sensing applications of 1D-nanostructured zinc oxide: Insights from density functional theory calculations. Prog Mater Sci 57:437–486

Zhai T, Fang X, Li L, Bando Y, Golberg D (2010) One-dimensional CdS nanostructures: synthesis, properties, and applications. Nanoscale 2:168–187

Tian J, Xu Z, Shen C, Liu F, Xu N, Gao H-J (2010) One-dimensional boron nanostructures: prediction, synthesis, characterizations, and applications. Nanoscale 2:1375–1389

Guo MY, Fung MK, Fang F, Chen XY, Ng AMC, Djurisic AB, Chan W (2011) ZnO and TiO2 1D nanostructures for photocatalytic applications. J Alloys Compd 509:1328–1332

Koenigsmann C, Wong S (2011) One-dimensional noble metal electrocatalysts: a promising structural paradigm for direct methanol fuel cells. Energy Environ Sci 4:1045–1528

Kim B, Chung H, Kim W (2012) High-performance supercapacitors based on vertically aligned carbon nanotubes and nonaqueous electrolytes. Nanotechnology 23:155401

Doytcheva M, Kaiser M, De Jonge N (2006) In situ transmission electron microscopy investigation of the structural changes in carbon nanotubes during electron emission at high currents. Nanotechnology 17:3226–3233

Cao Q, Rogers J (2009) Ultrathin films of single-walled carbon nanotubes for electronics and sensors: a review of fundamental and applied aspects. Adv Mater 21:29–53

Duan X, Niu C, Sahi V, Chen J, Parce J, Empedocles S, Goldman J (2003) High-performance thin-film transistors using semiconductor nanowires and nanoribbons. Nature 425:274–278

Tsang C, Liu Y, Kang Z, Ma D, Wong N, Lee S (2009) Metal (Cu, Au)-modified silicon nanowires for high-selectivity solvent-free hydrocarbon oxidation in air. Chem Comm 39:5829–5831

Schmidt V, Wittemann J, Senz S, Gosele U (2009) Silicon nanowires: a review on aspects of their growth and their electrical properties. Adv Mater 21:2681–2702

Burek M, Budiman A, Jahed Z, Tamura N, Kunz M, Jin S, Han S, Lee G, Zamecnik C, Tsui T (2011) Fabrication, microstructure, and mechanical properties of tin nanostructures. Mater Sci Eng A 528:5822–5832

Wagner R, Ellis W (1964) Vapor–liquid–solid mechanism of single crystal growth. Appl Phys Lett 4:89–90

McIlroy D, Zhang D, Kranov Y, Norton M (2001) Nanosprings. Appl Phys Lett 79:1540–1542

Panda D, Tseng T (2013) One-dimensional ZnO nanostructures: fabrication, optoelectronic properties, and device applications. J Mater Sci 48:6849–6877. doi:10.1007/s10853-013-7541-0

Thabethe B, Malgas G, Motaung D, Malwela T, Arendse C (2013) Self-catalytic growth of tin oxide nanowires by chemical vapor deposition process. Nanomater. doi:10.1155/2013/712361

Kodambaka S, Tersoff J, Reuter M, Ross F (2007) Germanium nanowire growth below the eutectic temperature. Science 316:729–732

Chan C, Peng H, Liu G, McIlwrath K, Zhang X, Huggins R, Cui Y (2008) High-performance lithium battery anodes using silicon nanowires. Nat Nanotechnol 3:31–35

Kukovitsky E, L’vov S, Sainov N (2000) VLS-growth of carbon nanotubes from the vapor. Chem Phys Lett 317:65–70

Chen C, Bisrat Y, Luo Z, Schaak R, Chao C, Lagoudas D (2006) Fabrication of single-crystal tin nanowires by hydraulic pressure injection. J Nanotechnol 17:367–374

Djenizian T, Hanzu I, Eyraud M, Santinacci L (2008) Electrochemical fabrication of tin nanowires: a short review. C R Chim 995–1003:995–1003

Schlesinger M, Paunovic M (2010) Modern electroplating. Wiley, Hoboken

Minzarik D, Jellesen M, Moller P, Wahlberg P, Ambat R (2009) Electrochemical migration on electronic chip resistors in chloride environments. IEEE Trans Device Mater Reliab 9:392–402

Feng B, Faruque F, Bao P, Chien A, Kumar S (2013) Double-sided tin nanowire arrays for advanced thermal interface materials. Appl Phys Lett. doi:10.1063/1.4791575

Singh N, Arthur T, Ling C, Matsui M, Mizuno F (2013) A high energy-density tin anode for rechargeable magnesium-ion batteries. Chem Commun 49:149–151

Zhu H, Jia Z, Chen Y, Weadock N, Wan J, Vaaland O, Han X, Li T, Hu L (2013) Tin anode for sodium-ion batteries using natural wood fiber as a mechanical buffer and electrolyte reservoir. Nano Lett 13:3093–3100

Cui Q, Rajathurai K, Jia W, Li X, Gao F, Lei Y, Gu Z (2010) Synthesis of single crystalline tin nanorods and their application as nanosoldering materials. J Phys Chem C 114:21938–21942

Sahaym U, Miller S, Norton M (2010) Effect of plating temperature on Sn surface morphology. Mater Lett 64:1547–1550

LeBret J, Norton M (2003) Electron microscopy study of tin whisker growth. J Mater Res 18:585–593

Zhang Y (2010) Physical description. In: Schlesinger M, Paunovic M (eds) Modern electroplating. Wiley, Hoboken, pp 169–172

Wang B, Yang Y, Wang C, Yang G (2005) Nanostructures and self-catalyzed growth of SnO2. J Appl Phys 98:073520-1–073520-5

Gorbunov A, Jost O, Pompe W, Graff A (2002) Solid–liquid–solid growth mechanism of single-wall carbon nanotubes. Carbon 40:113–118

Bockris JOM, Razumney G (1967) Fundamental aspects of electrocrystallization. Plenum Press, New York

Konenkamp R, Boedecker K, Lux-Steiner M, Poschenrieder M, Zenia F, Levy-Clement C, Wagner S (2000) Thin film semiconductor deposition on free-standing ZnO columns. Appl Phys Lett 77:2575–2577

She G, Shi W, Zhang X, Wong T, Cai Y, Wang N (2009) Template-free electrodeposition of one-dimensional nanostructures of tellurium. Cryst Growth Des 9:663–666

She G, Zhang X, Shi W, Cai Y, Wang N, Liu P, Chen D (2008) Template-free electrochemical synthesis of single-crystal CuTe nanoribbons. Cryst Growth Des 8:1789–1791

Spindt C, Brodiel I, Humphrey L, Westerberg E (1976) Physical properties of thin‐film field emission cathodes with molybdenum cones. J Appl Phys 47:5248–5263

Zhou J, Deng S, Gong L, Ding Y, Chen J, Huang J, Chen J, Xu N, Wang Z (2006) Growth of large-area aligned molybdenum nanowires by high temperature chemical vapor deposition: synthesis, growth mechanism, and device application. J Phys Chem B 110:10296–10302

Kamili A, Fray D (2011) Tin-based materials as advanced anode materials for lithium ion batteries. Rev Adv Mater Sci 27:14–24

Park C, Kim J, Kim H, Sohn H (2010) Li-alloy based anode materials for Li secondary batteries. Chem Soc Rev 39:3115–3141

Meschini I, Nobili F, Mancini M, Marassi R, Tossici R, Savoini A, Focarete ML, Croce F (2013) High-performance Sn@carbon nanocomposite anode for lithium batteries. J Power Sources 226:241–248

Lu W, Luo C, Li Y, Feng Y, Feng W, Zhao Y, Yuan X (2013) CoSn/carbon composite nanofibers for applications as anode in lithium-ion batteries. J Nanopart Res 15:1–11

Li X, Zhong Y, Cai M, Balogh MP, Wang D, Zhang Y, Li R, Sun X (2013) Tin-alloy heterostructures encapsulated in amorphous carbon nanotubes as hybrid anodes in rechargeable lithium ion batteries. Electrochim Acta 89:387–393

Song X (2013) A hierarchical hybrid design for high performance tin based Li-ion battery anodes. Nanotechnology 24:205401

Zhou X, Zou Y, Yang J (2013) Carbon supported tin-based nanocomposites as anodes for Li-ion batteries. J Solid State Chem 198:231–237

Zhuo K, Jeong MG, Chung CH (2013) Highly porous dendritic Ni–Sn anodes for lithium-ion batteries. J Power Sources 244:601–605

Wei Z, Mao H, Huang T, Yu A (2013) Facile synthesis of Sn/TiO2 nanowire array composites as superior lithium-ion battery anodes. J Power Sources 223:50–55

Chen X, Guo J, Gerasopoulos K, Langrock A, Brown A, Ghodssi R, Culver JN, Wang C (2012) 3D tin anodes prepared by electrodeposition on a virus scaffold. J Power Sources 211:129–132

Wu M, Wang C, Chen J, Wang F, Yi B (2013) Sn/carbon nanotube composite anode with improved cycle performance for lithium-ion battery. Ionics 19:1341–1347

Dimov N, Xia Y, Yoshio M (2007) Practical silicon-based composite anodes for lithium-ion batteries: fundamental and technological features. J Power Sources 171:886–893

Tamura N, Ohshita R, Fujimoto M, Fujitani S, Kamino M, Yonezu I (2002) Study on the anode behavior of Sn and Sn–Cu alloy thin-film electrodes. J Power Sources 107:48–55

Acknowledgements

This work was supported, in part, by the Washington Research Foundation and the Office of Research at Washington State University. A part of this work was performed at the Center for Integrated Nanotechnologies, a DOE-BES supported national user facility. Sandia is a multiprogram laboratory operated by Sandia Corporation, a Lockheed Martin Company, for the United States Department of Energy’s (DOE) National Nuclear Security Administration (NNSA) under contract DE-AC0494AL85000. Matthew Janish is partly supported by a GAANN Fellowship from the US Department of Education. Discussions with Joseph R. Michael, Bonnie McKenzie, and Summer R. Ferreira are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mackay, D.T., Janish, M.T., Sahaym, U. et al. Template-free electrochemical synthesis of tin nanostructures. J Mater Sci 49, 1476–1483 (2014). https://doi.org/10.1007/s10853-013-7917-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7917-1