Abstract

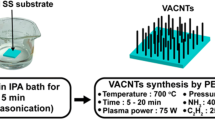

Compared with the ordinary vertically aligned carbon nanotube (VACNT) arrays, the carbon nanotubes in spinnable VACNT arrays have better alignment, higher density, and narrower diameter distribution. The synthesis of spinnable VACNT arrays is sensitive to the reaction condition and the repeatable prepared of spinnable VACNT arrays still need improvement. In this paper, spinnable VACNT arrays were grown by chemical vapor deposition from C2H2/Ar using Fe coated on Si wafers as a catalyst. With the aim of improving the yield and reproducibility of spinnable VACNT arrays, the reaction conditions were systematically investigated. The growth kinetics of VACNT arrays was also investigated. The rate of growth of VACNT arrays can reach 465 μm/min at the initial growth stage and the activation energy of VACNT array growth is determined to be 112.2 kJ/mol. Meanwhile, a collective growth model for the evolution of spinnable VACNT arrays is also proposed.

Similar content being viewed by others

References

Chen H, Roy A, Baek JB, Zhu L, Qu J, Dai LM (2010) Mater Sci Eng R 70:63

Small WR, Panhuis MIH (2007) Small 3:1500

Green MJ, Behabtu N, Pasquali M, Adams WW (2009) Polymer 50:4979

Ding MN, Star A (2012) Angew Chem Int Ed 51:7637

Fan SS, Chapline MG, Franklin NR, Tombler TW, Cassell AM, Dai HJ (1999) Science 283:512

Zhang LL, Zhao XS (2009) Chem Soc Rev 38:2520

Cheng FY, Tao ZL, Liang J, Chen J (2008) Chem Mater 20:667

Cao Q, Rogers JA (2009) Adv Mater 21:29

Avouris P, Chen ZH, Perebeinos V (2007) Nat Nanotechnol 2:605

Wei DC, Liu YQ (2008) Adv Mater 20:2815

Lan YC, Wang Y, Ren ZF (2011) Adv Phys 60:553

Liu K, Jiang KL, Wei Y, Ge SP, Liu P, Fan SS (2007) Adv Mater 19:975

Liao QL, Yang Y, Qi JJ, Zhang Y, Huang YH, Xia LS, Liu L (2010) Appl Phys Lett 96:073109

Niu CM, Sichel EK, Hoch R, Moy D, Tennent H (1997) Appl Phys Lett 70:1480

Dai HJ (2002) Acc Chem Res 35:1035

Jiang KL, Li QQ, Fan SS (2002) Nature 419:801

Zhang M, Atkinson KR, Baughman RH (2004) Science 306:1358

Zhang M, Fang SL, Zakhidow AA, Lee SB, Aliev AE, Williams CD, Atkinson KR, Baughman RH (2005) Science 309:1215

Liu K, Sun YH, Chen L, Feng C, Feng XF, Jiang KL, Zhao YG, Fan SS (2008) Nano Lett 8:700

Huynh CP, Hawkins SC, Redrado M, Barnes S, Lau D, Humphries W, Simon GP (2011) Carbon 49:1989

Jiang KL, Wang JP, Li QQ, Liu L, Liu CH, Fan SS (2011) Adv Mater 23:1154

Kuznetsov AA, Fonseca AF, Baughman RH, Zakhidov AA (2011) ACS Nano 5:985

Li QW, Zhang XF, DePaula RF, Zheng LX, Zhao YH, Stan L, Holesinger TG, Arendt PN, Peterson DE, Zhu YT (2006) Adv Mater 18:3160

Zhang SJ, Zhu LB, Minus ML, Chae HG, Jagannathan S, Wong CP, Kowalik J, Roberson LB, Kumar S (2008) J Mater Sci 43:4356. doi:10.1007/s10853-008-2558-5

Nakayama Y (2008) Jpn J Appl Phys 47:8149

Tran CD, Humphries W, Smith SM, Huynh C, Lucas S (2009) Carbon 47:2662

Zhang Q, Wang DG, Huang JQ, Zhou WP, Luo GH, Qian WZ, Wei F (2010) Carbon 48:2855

Hasegawa K, Noda S (2011) ACS Nano 5:975

Sugime H, Noda S, Maruyama S, Yamaguchi Y (2009) Carbon 47:234

Kim JH, Jang HS, Lee KH, Overzet LJ, Lee GS (2010) Carbon 48:538

Pint CL, Pheasant ST, Parra-Vasquez ANG, Horton C, Xu YQ, Hauge RH (2009) J Phys Chem C 113:4125

Huynh CP, Hawkins SC (2010) Carbon 48:1105

Feng XF, Liu K, Xie X, Zhou RF, Zhang LN, Li QQ, Fan SS, Jiang KL (2009) J Phys Chem C 113:9623

Liu K, Jiang KL, Feng C, Chen Z, Fan SS (2005) Carbon 43:2850

Bronikowski MJ (2007) J Phys Chem C 111:17705

Ting JM, Wu WY, Liao KH, Wu HH (2009) Carbon 47:2671

Wirth CT, Zhang C, Zhong GF, Hofmann S, Robertson J (2009) ACS Nano 3:3560

In JB, Grigoropoulos CP, Chernov AA, Noy A (2011) ACS Nano 5:9602

Yasuda S, Hiraoka T, Futaba DN, Yamada T, Yumura M, Hata K (2009) Nano Lett 9:769

Zhu LB, Xu JW, Xiao F, Jiang HJ, Hess DW, Wong CP (2007) Carbon 45:344

Stadermann M, Sherlock SP, In JB, Fornasiero F, Park HG, Artyukhin AB, Wang YM, De Yoreo JJ, Grigoropoulos CP, Bakajin O, Chernov AA, Noy A (2009) Nano Lett 9:738

Cui XW, Wei WF, Harrower C, Chen WX (2009) Carbon 47:3441

Yun YH, Shanov V, Tu Y, Subramaniam S, Schulz MJ (2006) J Phys Chem C 110:23920

Zhang M, Baughman R (2011) Assembly of carbon nanotube sheets. In: Marulanda JM (ed) Electronic properties of carbon nanotubes. InTech, Rijeka, p 1

Zhang M, Li J (2009) Mater Today 12:12

Eras G, Rouleau CM, Yoon M, Puretzky AA, Jackson JJ, Geohegan DB (2009) J Phys Chem C 113:15484

Bedewy M, Meshot ER, Guo HC, Verplogen EA, Lu W, Hart AJ (2009) J Phys Chem C 113:20576

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cui, Y., Wang, B. & Zhang, M. Optimizing reaction condition for synthesizing spinnable carbon nanotube arrays by chemical vapor deposition. J Mater Sci 48, 7749–7756 (2013). https://doi.org/10.1007/s10853-013-7596-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7596-y