Abstract

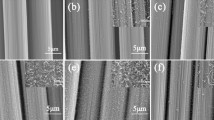

By engineering the fiber/matrix interface, the properties of the composite can be changed significantly. In this work, we increased the effective surface area of the fiber/matrix interface, to facilitate additional stress transfer between fibers and matrix, by grafting carbon nanotubes on to carbon fibers (in the form of carbon fabric) by two different methods: (1) chemical vapor deposition (CVD) method and (2) a purely chemical method. With the CVD process, carbon nanotubes (CNT) were directly grown on carbon fiber substrate using chemical vapors. For the chemical method, CNT with carboxyl groups were grafted on functionalized carbon fiber via a chemical reaction. The morphology of CNT/carbon fibers was examined by scanning electron microscope (SEM) which revealed uniform coverage of carbon fibers with CNT in both of CVD method and chemical grafting method. CNT-grafted woven carbon fibers were used to make carbon/epoxy composites, and their mechanical properties were measured using three-point bending and tension tests which showed that those with CNT-grafted carbon fiber reinforcements using the CVD process has 11 % higher tensile strength compared to those containing carbon fibers modified with the chemical method. Also, composites with CNT-grafted carbon fibers with chemical method showed 20 % higher tensile strength compared to composites with unmodified carbon fibers. The results of tensile test revealed that both CVD and chemical grafting could significantly improve the mechanical properties of the carbon fiber composites.

Similar content being viewed by others

References

Mangalgiri P (1999) Bull Mater Sci 22:657

Dai ZS, Zhang BY, Shi FH, Li M, Zhang ZG, Gu YZ (2011) Appl Surf Sci 257:8457

Rezaei F, Yunus R, Ibrahim NA (2009) Mater Des 30:260

Ye YP, Chen HB, Wu JS, Chan CM (2011) Compos B Eng 42:2145

Fan Z, Wu C, Chen J (2008) Carbon 46:365

Xie X-L, Mai Y-W, Zhou X-P (2005) Mater Sci Eng R: Rep 49:89

Siddiqui NA, Khan SU, Ma PC, Li CY, Kim JK (2011) Compos A Appl Sci Manuf 42:1412

Cho J, Daniel I (2008) Scripta Mater 58:533

Zhu J, Kim J, Peng H, Margrave JL, Khabashesku VN, Barrera EV (2003) Nano Lett 3:1107

Aldajah S, Haik Y (2012) Mater Des 34:379

Gonçalez V, Barcia FL, Soares BG (2006) J Braz Chem Soc 17:1117

Kaynak C, Orgun O, Tincer T (2005) Polym Test 24:455

Feraboli P, Masini A (2004) Compos B Eng 35:323

Zhang F-H, Wang R-G, He X-D, Wang C, Ren L-N (2009) J Mater Sci 44:3574. doi:10.1007/s10853-009-3484-x

Lee JS, Kang TJ (1997) Carbon 35:209

Zhou Y, Pervin F, Lewis L, Jeelani S (2008) Mater Sci Eng A 475:157

de Resende VG, Antunes EF, de Oliveira Lobo A, Oliveira DAL, Trava-Airoldi VJ, Corat EJ (2010) Carbon 48:3635

Zhao F, Huang YD (2011) J Mater Chem 21:3695

Thostenson ET, Li WZ, Wang DZ, Ren ZF, Chou TW (2002) J Appl Phys 91:6034

Mathur RB, Chatterjee S, Singh BP (2008) Compos Sci Technol 68:1608

Zhang Q, Liu J, Sager R, Dai L, Baur J (2009) Compos Sci Technol 69:594

An F, Lu CX, Li YH, Guo JH, Lu XX, Lu HB, He SQ, Yang Y (2012) Mater Des 33:197

Kim IT, Nunnery GA, Jacob K, Schwartz J, Liu XT, Tannenbaum R (2010) J Phys Chem C 114:6944

Rong HP, Han KQ, Li S, Tian YC, Yu MH (2012) J Appl Polym Sci 127:2033

Laachachi A, Vivet A, Nouet G, Ben Doudou B, Poilane C, Chen J, Bai JB, Ayachi M (2008) Mater Lett 62:394

Sharma SP, Lakkad SC (2011) Compos A Appl Sci Manuf 42:8

Lv P, Feng YY, Zhang P, Chen HM, Zhao NQ, Feng W (2011) Carbon 49:4665

Agnihotri P, Basu S, Kar KK (2011) Carbon 49:3098

Bekyarova E, Thostenson ET, Yu A, Kim H, Gao J, Tang J, Hahn HT, Chou T-W, Itkis ME, Haddon RC (2007) Langmuir 23:3970

Kim MT, Rhee KY, Lee JH, Hui D, Lau AKT (2011) Compos B Eng 42:1257

He XD, Zhang FH, Wang RG, Liu WB (2007) Carbon 45:2559

Ashrafi B, Guan JW, Mirjalili V, Zhang YF, Chun L, Hubert P, Simard B, Kingston CT, Bourne O, Johnston A (2011) Compos Sci Technol 71:1569

Davis DC, Wilkerson JW, Zhu J, Hadjiev VG (2011) Compos Sci Technol 71:1089

Xie J, Xin D, Cao H, Wang C, Zhao Y, Yao L, Ji F, Qiu Y (2011) Surf Coat Technol 206:191

Zhao JG, Liu L, Guo QG, Shi JL, Zhai GT, Song JR (2008) New Carbon Mater 23:12

Acknowledgements

Huaiping Rong would like to acknowledge the support from the National Basic Research Program (Grant No. 2011CB605600-G) of China (973 Program), the Ph.D. Students Innovation Project of Donghua university Shanghai city in China (Grant No. 9D10628), the China Scholarship Council (CSC) (2010- 2012), and the School of Materials Science and Engineering (MSE) at the Georgia Institute of Technology.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rong, H., Dahmen, KH., Garmestani, H. et al. Comparison of chemical vapor deposition and chemical grafting for improving the mechanical properties of carbon fiber/epoxy composites with multi-wall carbon nanotubes. J Mater Sci 48, 4834–4842 (2013). https://doi.org/10.1007/s10853-012-7119-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-7119-2