Abstract

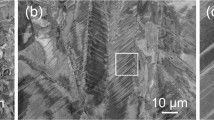

A type 316 austenitic stainless steel sheet with various texture components along its thickness was slightly cold-rolled and then sequentially annealed at 1000 °C for 80 and 150 min. The evolution of texture and the development of grain clusters in which the grains are interfaced by ∑3n (n = 0, 1, 2, 3…) boundaries (∑3n GC) were studied by electron backscatter diffraction (EBSD). The results show that the texture difference along the thickness was minimized, and large (greater than 400 μ) ∑3n GCs developed after cold rolling and annealing. In situ EBSD examination revealed that each ∑3n GC was developed by the oriented-growth (OG) of brass ({110}\( \langle 112\rangle \)), copper ({112}\( \langle 111\rangle \)) and C1 ({114}\( \langle 041\rangle \)) orientations (including their geometric variants). These orientations are intrinsically related to ∑3n misorientations. The abutting ∑3n GCs with grains of nearly the same or ∑3n-related orientations usually merged into a larger ∑3n GC or resulted in an effective disruption of the connectivity of the random high angle grain boundary network.

Similar content being viewed by others

References

Watanabe T (1984) Res Mech 11:47

Lin P, Palumbo G, Erb U, Aust KT (1995) Scripta Metall Mater 33:1387

Kumar M, Schwartz AJ, King WE (2002) Acta Mater 50:2599

Zhou Y, Aust KT, Erb U, Palumbo G (2001) Scripta Mater 45:49

Gertsman VY, Henager CH (2003) Interf Sci 11:403

Reed BW, Kumar M (2006) Scripta Mater 54:1029

Cayron C (2011) Acta Mater 59:252

Fang XY, Wang WG, Cai ZX, Qin CX, Zhou BX (2010) Mater Sci Eng A527:1571

Shimada M, Kokawa H, Wang ZJ (2002) Acta Mater 50:2331

Michiuchi M, Kokawa H, Wang ZJ, Sato YS, Sakai K (2006) Acta Mater 54:5179

Fang XY, Zhang K, Guo H, Wang WG, Zhou BX (2008) Mater Sci Eng A 487:7

King WE, Schwartz AJ (1998) Scripta Mater 38:440

Lee DS, Ryoo HS, Hwang SK (2003) Mater Sci Eng A 354:106

Xia S, Zhou BX, Chen WJ, Wang WG (2006) Scripta Mater 54:2019

Liu T, Shuang S, Li H, Zhou BX, Chen W (2011) Acta Metall Sinica 47:859

Cai Z, Wang WG, Fang XY, Guo H (2010) Acta Metall Sinica 46:769

Wang WG, Zhou BX, Guo H (2010) Mater Sci Forum 638–642:2864

Wang WG, Zhou BX, Rohrer GS, Guo H, Cai ZX (2010) Mater Sci Eng A527:3695

Gottstein G (1984) Acta Metall 32:1117

Mishin OV, Gertsman VY, Gottstein G (1997) Mater Characterization 38:39

Mishin OV, Gottstein G (1998) Mater Sci Eng A 249:71

Brandon DG (1966) Acta Metall 14:1479

Doherty RD, Hughes DA, Humphreys FJ, Jonas JJ et al (1997) Mater Sci Eng A238:219

Fullman RL, Fisher JC (1951) J Appl Phys 22:1350

Kurzydlowski KJ (1991) Scripta Metall 25:1099

Wang WG, Dai Y, Li JH, Liu BX (2011) Cryst Growth Des 11:2928

Acknowledgements

The authors gratefully acknowledge the financial support from the National Natural Science Foundation of China under Grants Nos. 50974147 and 51111120089/E0107, the Natural Science Foundation of Shandong Province under Grant No. 2009ZRB01176, and the Russian Foundation for Basic Research under Grant No. 11-08-91163.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fang, X., Liu, Z., Tikhonova, M. et al. Evolution of texture and development of ∑3n grain clusters in 316 austenitic stainless steel during thermal mechanical processing. J Mater Sci 48, 997–1004 (2013). https://doi.org/10.1007/s10853-012-6829-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6829-9