Abstract

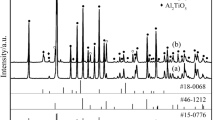

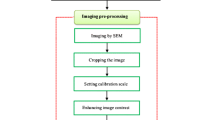

Porous mullite ceramics with unidirectionally oriented pores were prepared by an extrusion method using rayon fibers as the pore formers. Rayon fibers of 8.1, 9.6, 16.8, and 37.6 μm in diameter were used as the pore formers and were kneaded with alumina powder, kaolin clay, China earthen clay, and water to form pastes. These pastes were extruded into cylindrical tubes, dried, and fired at 1500 °C for 4 h. The apparent porosities ranged from 45.7 to 48.2 %. The pore size distributions showed a sharp peak at 9.4, 10.0, 15.6, and 30 μm with increasing fiber diameters. The height of the capillary rise was 1780, 1670, 1320, and 950 mm with increasing fiber diameter. The maximum capillary rise is much higher than previously reported. The contact angle and effective pore radius that determine the capillary rise ability were calculated by fitting the capillary rise curves using the Fries and Dreyer’s equation.

Similar content being viewed by others

References

Okada K, Isobe T, Katsumata K, Kameshima Y, Nakajima A, MacKenzie KJD (2011) Sci Tech Adv Mater 12:064701

Isobe T, Tomita T, Kameshima Y, Nakajima A, Okada K (2006) J Eur Ceram Soc 26:957

Isobe T, Kameshima Y, Nakajima A, Okada K, Hotta Y (2006) J Eur Ceram Soc 26:2213

Isobe T, Kameshima Y, Nakajima A, Okada K, Hotta Y (2006) J Porous Mater 13:269

Isobe T, Kameshima Y, Nakajima A, Okada K, Hotta Y (2007) J Eur Ceram Soc 27:53

Isobe T, Kameshima Y, Nakajima A, Okada K (2007) J Eur Ceram Soc 27:61

Okada K, Kameshima Y, Nakajima A, Madhusoodana CD (2007) J Heat Island Inst Int 2:1

Okada K, Uchiyama S, Isobe T, Kameshima Y, Nakajima A, Kurata T (2009) J Eur Ceram Soc 29:2491

Kubota T, Sugimoto H, Komiya H (2003) Rep Obayashi Tech Inst 67:1

Patro D, Bhattacharyya S, Jayaram V (2007) J Am Ceram Soc 90:3040

Washburn EW (1921) Phys Rev 17:273

Fries N, Dreyer M (2008) J Colloid Interface Sci 320:259

Fries N, Dreyer M (2008) J Colloid Interface Sci 327:125

He J, Hoyano A (2010) Build Environ 45:461

Maatta J, Piispanen M, Kuisma R, Kymalainen HR, Uusi-Rauva A, Hurme KR, Areva S, Sjoberg AM, Hupa L (2007) J Eur Ceram Soc 27:4555

Zhang X, Zhou J, Wang J, Jiang Y (2009) J Mater Sci 44:2938. doi:10.1007/s10853-009-3389-8

Cassie ABD, Baxter S (1944) Trans Faraday Soc 40:546

Cansoy CE, Erbil HY, Akar O, Akin T (2011) Colloids Surf A 386:116

Nakajima A (2007) Control of wettability of solid surfaces. Uchida Rokakuho, Tokyo, p 70

Acknowledgements

A part of this work was supported by the Grant for Application of Industrial Technology Innovation of the New Energy and Industrial Technology Development Organization of Japan (NEDO) under Contract No. 0827001. The authors thank Professor E. Sakai of the Tokyo Institute of Technology for permitting the use of the instrument for Hg porosimetry. We thank Professor K.J.D. MacKenzie of Victoria University of Wellington for critical reading and editing of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Popa, C., Okayasu, Y., Katsumata, Ki. et al. Capillary rise properties of porous mullite ceramics prepared by an extrusion method with various diameters of fiber pore formers. J Mater Sci 48, 941–947 (2013). https://doi.org/10.1007/s10853-012-6819-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6819-y