Abstract

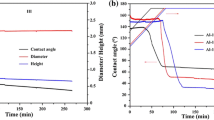

The wetting of (0001) α-alumina single crystals by Mg–Al alloys over a wide composition range at 1073 K was investigated using an improved sessile drop method in a flowing argon atmosphere. The initial contact angles are between 103° and 84°, almost linearly decreasing with increasing nominal Mg concentration, suggesting that the addition of Mg to Al improves the initial wettability. According to the evolution of contact angle and contact diameter, representative stages were identified to characterize the complex wetting behavior in the presence of evaporation. The wetting kinetics was dependent on the nominal Mg concentration in the alloy. Two patterns of “stick–slip” behavior were observed in the wetting process and interpreted by combining the effects of interfacial reaction and evaporation of magnesium. In addition, the dependence of the interfacial reaction on the Mg–Al alloy concentration was thermodynamically analyzed. The dominant reaction product at 1073 K should be MgO when x Mg > 9 mol%, while MgAl2O4 when x Mg < 9 mol%. However, because of the continuous consumption of Mg due to the evaporation and reaction, its concentration in the alloy progressively decreased with time. As a result, MgO formed usually earlier while MgAl2O4 later even for the alloys with higher than 9 mol% Mg.

Similar content being viewed by others

References

Delannay F, Froyen L, Deruyttere A (1987) J Mater Sci 22:1. doi:10.1007/BF01160545

Shen P, Zhang D, Lin QL, Shi LX, Jiang QC (2010) Mater Chem Phys 122:290

Fujii H, Izutani S, Matsumoto T, Kiguchi S, Nogi K (2006) Mater Sci Eng, A 417:99

Shi LX, Shen P, Zhang D, Jiang QC (2011) Mater Chem Phys 130:1125

Carnahan RD, Johnston TL, Li CH (1958) J Am Ceram Soc 41:343

Champion JA, Keene BJ, Sillwood JM (1969) J Mater Sci 4:39. doi:10.1007/BF00555046

John H, Hausner H (1986) J Mater Sci Lett 5:549

Ip SW, Kucharski M, Toguri JM (1993) J Mater Sci Lett 12:1699

Zhou XB, De Hosson JThM (1995) J Mater Sci 30:3571. doi:10.1007/BF00351867

Levi G, Kaplan WD (2002) Acta Mater 50:75

Saiz E, Tomsia AP, Cannon RM (1998) Acta Mater 46:2349

Saiz E, Tomsia AP, Suganuma K (2003) J Eur Ceram Soc 23:2787

Ksiazek M, Sobczak N, Mikulowski B, Radziwill W, Surowiak I (2002) Mater Sci Eng, A 324:162

Jonas TR, Cornie JA, Russell KC (1995) Metall Mater Trans A 26:1491

Aguilar-Santillan J (2010) Metall Mater Trans A 41:676

Laurent V, Chatain D, Chatillon C, Eustathopoulos N (1988) Acta Metall 36:1797

Shen P, Fujii H, Matsumoto T, Nogi K (2003) Acta Mater 51:4897

Brennan JJ, Pask JA (1968) J Am Ceram Soc 51:569

Weirauch DA Jr (1988) J Mater Res 3(4):729

Klinter AJ, Mendoza-Suarez G, Drew RAL (2008) Mater Sci Eng, A 495:147

Shen P, Fujii H, Matsumoto T, Nogi K (2004) J Am Ceram Soc 87:2151

Barin I (1995) Thermochemical data of pure substances, 3rd edn. Wiley-VCH Verlag GmbH, Weinheim

McLeod AD, Gabryel CM (1992) Metall Mater Trans A 23:1279

Massalski TB (1996) Binary alloys phase diagrams. ASM International, (CD–ROM)

Hultgren R, Desai PD, Hawkins DT, Gleiser M, Kelley KK (1973) Selected values of the thermodynamic properties of binary alloys. ASM, Metals Park, OH

Zhong WM, L’espérance G, Suétry M (1995) Metall Mater Trans A 26:2625

Hallestedt B, Liu ZK, Agren J (1990) Mater Sci Eng, A 129:135

Iida T, Guthrie RIL (1993) The physical properties of liquid metals. Clarendon Press, Oxford

Eustathopoulos N (1998) Acta Mater 46:2319

Zhang D (2012) Wetting of ceramics by molten Mg and effect of evaporation. PhD thesis, Jilin University, China (see the supplementary material)

Shen P, Fujii H, Matsumoto T, Nogi K (2004) Acta Mater 52:887

Mullins WW (1958) Acta Metall 6:414

Nowak N (2010) PhD thesis, Foundry Research Institute, Krakow, Poland

Lea C, Molinari C (1984) J Mater Sci 19:2336. doi:10.1007/BF01058110

Keene BJ (1993) Int Mater Rev 38:157

Acknowledgements

This work was supported by National Natural Science Foundation of China (No. 50871045), National Basic Research Program of China (973 program) (No. 2012CB619600), Key Project of Chinese Ministry of Education (No. 108043) and Graduate Innovation Fund of Jilin University (No. 20121086).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shi, L., Shen, P., Zhang, D. et al. Wetting of (0001) α-alumina single crystals by molten Mg–Al alloys in the presence of evaporation. J Mater Sci 47, 8372–8380 (2012). https://doi.org/10.1007/s10853-012-6784-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6784-5