Abstract

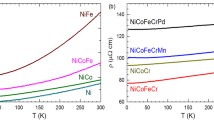

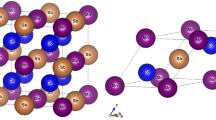

The temperature dependencies of the γ(f.c.c.)-Ni/γ′-Ni3Al(L12) interfacial free energy for the {100}, {110}, and {111} interfaces are calculated using first-principles calculations, including both coherency strain energy and phonon vibrational entropy. Calculations performed including ferromagnetic effects predict that the {100}-type interface has the smallest free energy at different elevated temperatures, while alternatively the {111}-type interface has the smallest free energy when ferromagnetism is absent; the latter result is inconsistent with experimental observations of γ′-Ni3Al-precipitates in Ni–Al alloys faceted strongly on {100}-type planes. The γ(f.c.c.)-Ni/γ′-Ni3Al interfacial free energies for the {100}, {110}, and {111} interfaces decrease with increasing temperature due to vibrational entropy. The predicted morphology of γ′-Ni3Al(L12) precipitates, based on a Wulff construction, is a Great Rhombicuboctahedron (or Truncated Cuboctahedron), which is one of the 13 Archimedean solids, with 6-{100}, 12-{110}, and 8-{111} facets. The first-principles calculated morphology of a γ′-Ni3Al(L12) precipitate is in agreement with experimental three-dimensional atom-probe tomographic observations of cuboidal L12 precipitates with large {100}-type facets in a Ni-13.0 at.% Al alloy aged at 823 K for 4096 h. At 823 K this alloy has a lattice parameter mismatch of 0.004 ± 0.001 between the γ(f.c.c.)-Ni-matrix and the γ′-Ni3Al-precipitates.

Similar content being viewed by others

References

Sims CT (1987) In: Sims CT, Stoloff NS, Hagel WC (eds) Superalloys II high—temperature materials for aerospace and industrial power. Wiley, New York

Ardell AJ (1995) Interf Sci 3:119

Ardell AJ (2011) J Mater Sci 46:4832. doi:10.1007/s10853-011-5395-x

Mishin Y (2004) Acta Mater 52:1451. doi:10.1016/j.actamat.2003.11.026

Baldan A (2002) J Mater Sci 37:2379. doi:10.1023/A:1015408116016

Wolverton C, Zunger A (1999) Phys Rev B 59:12165

Calderon HA, Voorhees PW, Murray JL, Kostorz G (1994) Acta Metall Mater 42:991

DL Price, BR Cooper (1996) In: Materials theory, simulations, and parallel algorithms. MRS Proceedings. Cambridge University Press, Cambridge 408: 463

Amouyal Y, Mao ZG, Seidman DN (2008) Appl Phys Lett 93:201905. doi:10.1063/1.3026745 Artn 201905

Lifshitz IM, Slyozov VV (1961) J Phys Chem Solids 19:35

Wagner C (1961) Z Electrochem 65:581

Wagner R, Kampmann R, Voorhees PW (2001) Homogeneous second-phase precipitation. Wiley-VCH, Weinheim

Ardell AJ, Nicholson RB (1966) J Phys Chem Solids 27:1793

Ardell AJ, Nicholson RB, Eshelby JD (1966) Acta Metall Mater 14:1295

Kresse G, Furthmueller J (1996) Phys Rev B 54:11169

Kresse G, Furthmuller J (1996) Comp Mater Sci 6:15

Kresse G, Hafner J (1993) Phys Rev B 47:558

Kresse G, Hafner J (1994) Phys Rev B 49:14251

Kresse G, Joubert D (1999) Phys Rev B 59:1758

Paier J, Hirschl R, Marsman M, Kresse G (2005) J Chem Phys 122:234102. doi:10.1063/1.1926272 Artn234102

Yin MT, Cohen ML (1980) Phys Rev Lett 45:1004

Ho KM, Fu CL, Harmon BN, Weber W, Hamann DR (1982) Phys Rev Lett 49:673

Lam PK, Cohen ML (1982) Phys Rev B 25:6139

Mishima Y, Ochiai S, Suzuki T (1985) Acta Metall Mater 33:1161

van de Walle A, Ceder G (2002) Rev Mod Phys 74:11

Maradudin AA (1971) Theory of lattice dynamics in the harmonic approximation, 2nd edn. Academic Press, New York

Huntington HB, Shirn GA, Wajda ES (1955) Phys Rev 99:1085

Srinivasan R, Banerjee R, Hwang JY, et al (2009) Phys Rev Lett 102. Artn 086101. doi:10.1103/Physrevlett.102.086101

Mao Z, Sudbrack CK, Yoon KE, Martin G, Seidman DN (2006) Nat Mater 6:210

Sluiter M, Kawazoe Y (1996) Phys Rev B 54:10381

Ardell AJ, Ozolins V (2005) Nat Mater 4:309. doi:10.1038/Nmat1340

Clouet E, Nastar M, Sigli C (2004) Phys Rev B 69:064109. doi:10.1103/Physrevb.69.064109 Artn 064109

Marquis EA, Seidman DN (2001) Acta Mater 49:1909

Wulffman package from NIST. http://www.ctcms.nist.gov/wulffman/

Plotnikov EY PhD in progress, Northwestern University, arc.nucapt.northwestern.edu

Bajikar SS, Larson DJ, Kelly TF, Camus PP (1996) Ultramicroscopy 65:119

Kelly TF, Camus PP, Larson DJ, Holzman LM, Bajikar SS (1996) Ultramicroscopy 62:29

Kelly TF, Larson DJ (2000) Mater Charact 44:59

Karnesky RA, Isheim D, Seidman DN (2007) Appl Phys Lett 91. Artn 013111. doi:10.1063/1.2753097

Bunton JH, Olson JD, Lenz DR, Kelly TE (2007) Microsc Microanal 13:418. doi:10.1017/S1431927607070869

Seidman DN, Stiller K (2009) MRS Bull 34:717

Seidman DN (2007) Annu Rev Mater Res 37:127

Sudbrack CK, Isheim D, Noebe RD, Jacobson NS, Seidman DN (2004) Microsc Microanal 10:355. doi:10.1017/S1431927604040589

Acknowledgements

This research is supported by National Science Foundation, Division of Materials Research, number DMR-080461, Dr. A. J. Ardell, and Dr. E. Taleff, grant monitors. Dr. R. D. Noebe, NASA Glenn Research Center, Cleveland, Ohio, is kindly thanked for processing, aging and preparing the Ni-13 at.% Al for atom-probe tomography. We thank Prof. C. Wolverton for many helpful discussions and suggestions. Atom-probe tomographic measurements were performed at the Northwestern University Center for Atom-Probe Tomography (NUCAPT). The LEAP tomograph was purchased and upgraded with funding from NSF-MRI (DMR-0420532) and ONR-DURIP (N00014-0400798, N00014-0610539, NOOO14-0910781) grants and ISEN.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mao, Z., Booth-Morrison, C., Plotnikov, E. et al. Effects of temperature and ferromagnetism on the γ-Ni/γ′-Ni3Al interfacial free energy from first principles calculations. J Mater Sci 47, 7653–7659 (2012). https://doi.org/10.1007/s10853-012-6399-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6399-x