Abstract

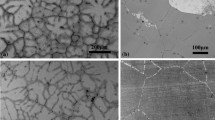

The effects of Ag addition on the microstructure and thermal stability of 6156 Al–Mg–Si–Cu alloy were investigated by means of hardness measurement, tensile tests, differential scanning calorimetry, and transmission electron microscopy. The results showed that addition of small amount of Ag to 6156 alloy did not change the precipitation sequence mainly β″ and Q′ strengthening phase but slightly accelerated the age-hardening rate and increased peak hardness at the same aging condition. The tensile properties enhanced about 30 MPa at the room temperature or thermal exposure at lower temperature (<100 °C). With the exposed temperature and time increased to 150 °C for 1000 h, almost no difference between the Ag-containing and Ag-free alloys. When exposed at 200 °C, the tensile strength of Ag-containing alloy became lower than that of Ag-free alloy because of the coarsening precipitations in matrix and boundary observed by TEM observed. For both alloys, thermal exposure at temperatures 100 °C for long time periods had no significant effect on tensile properties. Loss in strength was small and large with prolonging the exposure time at 150 and 200 °C, respectively.

Similar content being viewed by others

References

Fortin PE, Bull MJ, Moore DM (1983). In: SAE International Congress & Exposition, Detroit, MI, SAE Paper No. 830096

Starke EA Jr, Csontos AA (1998). In: Proceedings of 6th international conference on aluminum alloys. p 2077

Dif R, Bechet D, Wamer T, Ribes H (1998). In: Proceedings of 6th international conference on aluminum alloys, vol 3. p 1991

Dif R, Bes B, Wamer T, Lequeu P, Ribes H, Lassince P (2001) Advances in the metallurgy of aluminum alloys. ASM International, Materials Park, p 390

Schmidt HJ, Schmidt-Brandecker B, Ohrloff N, Fleischer T (1999) In: Proceedings of 20th symposium international committee on aeronautical fatigue I. p 537

Hinrichsen J (2001) In: Peters M, Kaysser WA (eds) Advanced aerospace materials. Deutsche Gesellschaft für Luft-und Raumfahrt, Bonn, Germany, p 3

Li Q, Shenoy RN (1997) J Mater Sci 32:3401. doi:10.1023/A:1018664515422

Liu XY, Pan QL, Lu ZL, Cao SF, He YB, Li WB (2011) Adv Mater Res 152–153:1426

Chang CH, Lee SL, Lin JC, Yeh MS, Jeng RR (2005) Mater Chem Phys 91:454

Reich L, Murayama M, Hono K (1998) Acta Mater 46:6053

Matsuda K, Fukaya K, Zou Y, Kawabata T, Uetani Y, Ikeno S (2004) Mater Forum 28:424

Zou Y, Matsuda K, Kawabata T, Himuro Y, Ikeno S (2004) Mater Forum 28:539

Furihata A, Matsuda K, Nakamura JY, Ikeno S, Uetina Y (2006) Mater Sci Forum 519–521:507

Nakamura J, Matsuda K, Nakamura Y, Sato T, Ikeno S (2006) Mater Sci Forum 519–521:511

Dutta I, Allen SM (1991) J Mater Sci Lett 10:323

Miao WF, Laughlin DE (2000) Metall Trans A 31A:361

Lloyd DJ, Evans DR, Gupta AK (2000) Can Metall Q 39:475

Edwards GA, Stiller K, Dunlop GL, Couper MJ (1998) Acta Mater 46:3893

Gaber A, Ali AM, Matsuda K, Kawabata T, Yamazaki T, Ikeno S (2007) J Alloys Compd 432:149

Matsuda K, Ikeno S, Matsui H, Sato T, Terayama K, Uetani Y (2005) Metall Trans A 36A:2007

Yassar RS, Field DP, Weiland H (2005) Scripta Mater 53:299

Vissers R, Huis MA, Jansen J, Zandbergen HW, Marioara CD, Andersen SJ (2007) Acta Mater 55:3815

Mahadevan S, Giridhar A, Singh AK (1986) J Non-Cryst Solids 88:11

Rysava N, Spasov T, Tichy L (1987) J Therm Anal 32:1015

Gaber A, Matsuda K, Ali AM, Zou Y, Ikeno S (2004) Mater Sci Technol 20:1627

Prabhu N, Howe JM (1992) Metall Trans A 23A:135

Callister WD Jr (ed) (1991) In: Materials science and engineering: an introduction, 2nd edn. Wiley, New York, p 536

Ohmori Y, Doan LC, Nakai K (2002) Mater Trans 43:246

Jin M, Li J, Shao GJ (2007) J Alloys Compd 437:146

Matsuda K, Teguri D, Uetanic Y, Sato T, Ikeno S (2002) Scripta Mater 47:833

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, H., Zheng, Z., Lin, Y. et al. Effects of Ag addition on the microstructure and thermal stability of 6156 alloy. J Mater Sci 47, 4101–4109 (2012). https://doi.org/10.1007/s10853-012-6264-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6264-y