Abstract

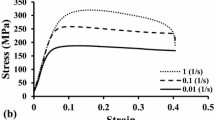

The hot deformation characteristics and constitutive analysis of Inconel (IN) 600 superalloy were investigated at elevated temperatures. Hot compressive tests were carried out in the temperature and strain rate ranging from 900 to 1150 °C and 1 × 10−3–10 s−1, respectively. The flow behavior analyses and microstructural observations indicate that the softening mechanisms were related to dynamic recrystallization (DRX) and grain growth. DRX played a dominant role in the microstructural evolution at low temperatures (or high strain rates). DRX was the dominant softening effect at low strains on testing at high temperatures with low strain rates, whereas growth of the dynamically recrystallized grains was responsible for softening at high strains. The flow stress of IN 600 was fitted well by the constitutive equation of the hyperbolic sine function under the deformation conditions performed in this study. A constitutive equation as a function of strain was established through a simple extension of the hyperbolic sine constitutive relation.

Similar content being viewed by others

References

McQueen HJ, Imbert CAC (2004) J Alloys Compd 378:35

Fang YL, Liu ZY, Song HM, Jiang LZ (2009) Mater Sci Eng A A526:128

Guo SL, Li DF, Pen HJ, Guo QM, Hu J (2011) J Nucl Mater 410:52

Semiatin SL, Fagin PN, Glavicic MG, Raabe D (2004) Scripta Mater 50:625

Medeiros SC, Prasad YVRK, Frazier WG, Srinivasan R (2000) Mater Sci Eng A A293:198

Ponge D, Gottstein G (1998) Acta Mater 46:69

Sellars C, Tegart WM (1966) Acta Metall 14:1136

Sellars C, Tegart WM (1972) Int Metall Rev 17:1

McQueen HJ, Ryan ND (2002) Mater Sci Eng A A322:43

Hsu SE, Edwards GR, Sherby OD (1983) Acta Metall 31:763

Cai DY, Xiong LY, Liu WC, Sun GD, Yao M (2009) Mater Des 30:921

Yuan H, Liu WC (2005) Mater Sci Eng A A408:281

Thomas A, El-Wahabi M, Cabrera JM, Prado JM (2006) J Mater Process Technol 177:469

Jiang P, Fu WT, Wang ZH, Bai XH, Zhao XC, Lv ZQ (2011) J Mater Sci 46:4654. doi:10.1007/s10853-011-5371-5

Farnoush H, Momeni A, Dehghani K, Aghazadeh Mohandesi J, Keshmiri H (2010) Mater Des 31:220

Slooff FA, Zhou J, Duszczyk J, Katgerman L (2008) J Mater Sci 43:7165. doi:10.1007/s10853-008-3014-2

Luo J, Li MQ, Yu WX, Li H (2009) Mater Sci Eng A A504:90

Lin YC, Liu G (2009) Mater Sci Eng A A523:139

Bombač D, Fazarinc M, Kugler G, Spajić S (2008) RMZ Mater Geoenviron 55:319

Wang Y, Shao WZ, Zhen L, Yang L, Zhang XM (2008) Mater Sci Eng A A497:479

Liu Y, Hu R, Li JS, Kou HC, Li HW, Chang H, Fu HZ (2009) J Mater Process Technol 209:4020

Pruthi DD, Anand MS, Agarwala RP (1977) J Nucl Mater 6:206

Prasad YVRK, Rao KP, Hort N, Kainer KU (2008) Mater Lett 62:4207

Zhang H, Konopleva EV, McQueen HJ (2001) Mater Sci Eng A A319–321:711

Zener C, Hollomon JH (1944) J Appl Phys 15:22

Dehghan-Manshadi A, Barnett MR, Hodgson PD (2008) Mater Sci Eng A A485:664

Rath BB, Imam MA, Pande CS (2000) Mater Phys Mech 1:61

Pande CS, Ashraf Imam M (2009) Mater Sci Eng A A512:82

Mahajan S, Pande CS, Imam MA, Rath BB (1997) Acta Mater 45:2633

Slooff FA, Zhou J, Duszczyk J, Katgerman L (2007) Constitutive behaviour of wrought magnesium alloy AZ61. In: Beals RS, Luo AA, Neelameggham NR, Pekguleryuz MO (eds) Magnesium Technology 2007. TMS, Warrendale, p 363

Slooff FA, Zhou J, Duszczyk J, Katgerman L (2007) Scripta Mater 57:759

Verlinden B, Suhadi A, Delaey L (1993) Scripta Metall 28:1441

Momeni A, Dehghani K (2011) Mater Sci Eng A A528:1448

Acknowledgements

This study was financially supported by the Nanopowder and Thin Film Technology Center, ITRI South, Industrial Technology Research Institute.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, HY., Zhu, FJ., Wang, SC. et al. Hot deformation characteristics and strain-dependent constitutive analysis of Inconel 600 superalloy. J Mater Sci 47, 3971–3981 (2012). https://doi.org/10.1007/s10853-012-6250-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6250-4