Abstract

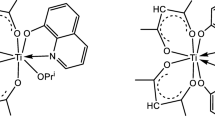

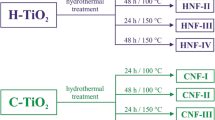

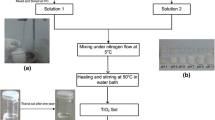

Nanostructured titanates with different morphologies such as nanoflakes, nanotubes, and nanofibers have been selectively synthesized by a simple solvothermal treatment of commercial anatase TiO2 using the mixed water–ethanol cosolvent at low alkaline concentration. The effects of solvothermal temperature, volume ratio of H2O to C2H5OH, amount of NaOH and solvents on the formation of titanate nanostructures have been systematically studied through X-ray diffraction (XRD), Raman spectroscopy, scanning electron microscopy (SEM), and transmission electron microscopy (TEM). At low concentration of NaOH solution (the actual concentration of OH− in the solution is only 0.58 M), different titanate nanostructures are achieved by simply changing the volume ratio of H2O to C2H5OH at 180 °C and titanate nanotubes can be synthesized between 100 and 180 °C. A probable formation mechanism is proposed based on XRD, SEM and TEM analysis. The influence of cosolvent on the transformation from anatase TiO2 to titanate is also investigated.

Similar content being viewed by others

References

Iijima S (1991) Nature 56:354

Hu JT, Odom TW, Lieber CM (1999) Acc Chem Res 32:435

Bavykin DV, Friedrich JM, Walsh FC (2006) Adv Mater 18:2807

Niu LL, Shao MW, Wang S, Lu L, Gao HZ, Wang J (2008) J Mater Sci 43:1510. doi:10.1007/s10853-007-2374-3

Bavykin DV, Lapkin AA, Plucinski PK, Friedrich JM, Walsh FC (2005) J Phys Chem B 109:19422

Armstrong AR, Armstrong G, Canales J, Bruce PG (2005) J Power Sources 146:501

Sun X, Li Y (2003) Chem Eur J 9:2229

Kasuga T, Hiramatsu M, Hoson A, Sekino T, Niihara K (1998) Langmuir 14:3160

Kasuga T, Hiramatsu M, Hoson A, Sekino T, Niihara K (1999) Adv Mater 11:1307

Morgan DL, Triani G, Blackford MG, Raftery NA, Frost RL (2011) J Mater Sci 46:548. doi:10.1007/s10853-010-5016-0

Zhao B, Chen F, Jiao YC, Zhang JL (2010) J Mater Chem 20:7990

Zhao B, Chen F, Gu XN, Zhang JL (2010) Chem Asian J 5:1546

Zhao B, Chen F, Qu WW, Zhang JL (2009) J Solid State Chem 182:2225

Bavykin DV, Parmon VN, Lapkin AA, Walsh FC (2004) J Mater Chem 14:3370

Kukovecz Á, Hodos M, Horváth E, Radnöczi G, Kónya Z, Kiricsi I (2005) J Phys Chem B 109:17781

Morgan DL, Zhu HY, Frost RL, Waclawik ER (2008) Chem Mater 20:3800

Morgan DL, Liu HW, Frost RL, Waclawik ER (2010) J Phys Chem C 114:101

Yuan ZY, Su BL (2004) Colloids Surf A 241:173

Zhu HY, Lan Y, Gao XP, Ringer SP, Zheng ZF, Song DY, Zhao JC (2005) J Am Chem Soc 127:6730

Wen B, Liu C, Liu Y (2005) Chem Lett 34:396

Wen B, Liu C, Liu Y (2005) New J Chem 29:969

Wang Q, Wen Z, Li J (2006) Inorg Chem 45:6944

Das K, Panda S, Chaudhuri S (2008) J Cryst Growth 310:3792

Bavykin DV, Kulak AN, Walsh FC (2008) Cryst Growth Des 20:3800

Huang JQ, Cao YG, Wang ML, Huang CG, Deng ZH, Tong H, Liu ZG (2010) J Phys Chem C 114:14748

Chen Q, Du GH, Zhang S, Peng LM (2002) Acta Crystallogr B58:587

Kim S, Yun Y, Oh H, Hong SH, Roberts CA, Routray K, Wachs IE (2010) J Phys Chem Lett 1:130

Liu HW, Yang DJ, Zheng ZF, Ke XB, Waclawik E, Zhu HY, Frost RL (2010) J Raman Spectrosc 41:1331

Kolen’ko YV, Kovnir KA, Gavrilov AI, Garshev AV, Frantti J, Lebedev OI, Churagulov BR, Tendeloo GV, Yoshimura M (2006) J Phys Chem B 110:4030

Wang YQ, Hu GQ, Duan XF, Sun HL, Xue QK (2002) Chem Phys Lett 365:427

Zhang S, Peng TY, Chen Q, Du GH, Dawson G, Zhou WZ (2003) Phys Rev Lett 91:256103

Zhang S, Chen Q, Peng LM (2005) Phys Rev B 71:014104

Ma R, Bando Y, Sasaki T (2004) J Phys Chem B 108:2115

Yao BD, Chan YF, Zhang XY, Zhang WF, Yang ZY, Wang N (2003) Appl Phys Lett 82:281

Wu D, Liu J, Zhao X, Li A, Chen Y, Ming N (2006) Chem Mater 18:547

Bavykin DV, Cressey BA, Walsh FC (2007) Aust J Chem 60:95

Li J, Zhou ZX, Zhu LH, Xu K, Tang HQ (2007) J Phys Chem C 111:16768

Acknowledgements

This work has been supported by National Basic Research Program of China (973 Program, 2010CB732306), National Nature Science Foundation of China (21007016 and 20977030), the Project of International Cooperation of the Ministry of Science and Technology of China (2011DFA50530), Science and Technology Commission of Shanghai Municipality (10520709900 and 10JC1403900) and the Fundamental Research Funds for the Central Universities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shen, X., Zhang, J. & Tian, B. Facile tailoring of titanate nanostructures at low alkaline concentration by a solvothermal route. J Mater Sci 47, 3855–3866 (2012). https://doi.org/10.1007/s10853-011-6241-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-6241-x