Abstract

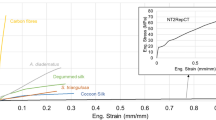

Industrial Bombyx mori silk yarns have been degummed and mechanically tested. The principal mechanical characteristics of these yarns have been obtained and compared, before and after degumming. It has been observed that the sericin sheath surrounding the silk fibres plays a bigger part in determining behaviour than had been expected. The initial gradients of the force/strain curves were reduced by 21% when the sericin were removed and this was associated with a 20% fall in the failure forces obtained. The force/strain curves up to failure of the yarns were completely modified with the removal of the sericin and showed a multi-level fracture surface rather than a net failure. This variation was not due to the treatment involved in removing the sericin. The role of the sericin sheath has been studied using scanning electron microscopy with in situ tensile testing. The sericin have been seen to act like a matrix, as in a fibre composite with the silk fibres as the reinforcements. As in a composite, the force transfer between the sericin sheath and the inner fibre is controlled by shear forces at the interface between the two and result in the modified fracture morphology and physical properties.

Similar content being viewed by others

Abbreviations

- SEM:

-

Scanning electron microscope

- St:

-

Standard industrial silk yarn

- Std:

-

Degummed standard industrial silk yarn

- Stf:

-

Standard industrial silk yarn extracted fibre

References

Bartow B, Buffalo MD (1916) J Bone Jt Surg 2:217

Meinel L, Hofmann S, Karageorgiou V, Zichner L, Langer R, Kaplan D, Vunjak-Novakovic G (2004) Biotechnol Bioeng 88:379

Vollrath F, Porter D (2006) Soft Matter 2:377

Altman GH, Diaz F, Jakuba C, Calabro T, Horan RL, Chen J, Lu H, Richmond J, Kaplan D (2003) Biomaterials 24:401

Vepari C, Kaplan DL (2007) Prog Polym Sci 32:991

Beaulard MF (1903) J Phys 4:785

Pérez-Rigueiro J, Viney C, Llorca J, Elices M (1998) J Appl Polym Sci 70:2439

Parthasarathy KM, Naresh MD, Arumugam V, Subramaniam V, Sanjeevi R (1996) J Appl Polym Sci 59:2049

Martel A, Burghammer M, Davies RJ, Riekel C (2007) Biomacromolecules 8:3548

Nakamae K, Nishino T, Ohkubo H (1989) Polymer 30:1243

Seydel T, Kölln K, Krasnov I, Diddens I, Hauptmann N, Helms G, Ogurreck M, Kang SG, Koza MM, Müller M (2007) Macromolecules 40:1035

Krasnov I, Diddens I, Hauptmann N, Helms G, Ogurreck M, Seydel T, Funari SS, Müller M (2008) Phys Rev Lett 100:1

Asakura T, Demura M, Date T, Miyashita N, Ogawa K, Williamson MP (1997) Biopolymers 41:193

Lefèvre T, Rousseau M–E, Pézolet M (2007) Biophys J 92:2885

Lefèvre T, Paquet-Mercier F, Lesage S, Rouseau M–E, Bédard S, Pézolet M (2009) Vib Spectrosc 51:136

Pérez-Rigueiro J, Elices M, Plaza GR, Guinea GV (2007) Macromolecules 40:5360

Jauzein V, Colomban P (2009) In: Bunsell AR (ed) Handbook of tensile properties of textile and technical fibres. Woodhead Publishing, Cambridge, pp 144–172

Pérez-Rigueiro J, Viney C, Llorca J, Elices M (2000) J Appl Polym Sci 75:1270

Pérez-Rigueiro J, Elices M, Llorca J, Viney C (2002) J Appl Polym Sci 84:1431

Jiang P, Liu H, Wang C, Wu L, Huang J, Guo C (2006) Mater Lett 60:919

Chen F, Porter D, Vollrath F (2009) 17th International conference on composite materials

Bunsell AR, Hearle JWS, Hunter R (1971) J Phys E 4:868

Ki CS, Kim JW, Oh HJ, Lee KH, Park YH (2007) Int J Biol Macromol 41:346

Morton W, Hearle JWS (2008) In: Morton WE and Hearle JWS (eds) Physical properties of textile fibres, 4th edn. The Textile Institute/CRC, Manchester

Bunsell AR, Renard J (2005) Fundamentals of Fibre Reinforced Composite Materials. Institute of Physics/CRC, London

Acknowledgement

This study was supported by the Agence Nationale pour la Recherche under the project entitled ‘ANR blanche Nanosoie’. Further support from Perrin & fils which provided the material is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jauzein, V., Bunsell, A. Bio-composite aspects of silk: the sericin sheath acting as a matrix. J Mater Sci 47, 3082–3088 (2012). https://doi.org/10.1007/s10853-011-6141-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-6141-0