Abstract

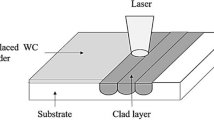

In this article, laser cladding process with a blown powder feeding was used to deposit nickel-based IN-625 superalloy, cobalt-based hardfacing Stellite 6 alloy and high-vanadium CPM 10V tool steel onto a similar or dissimilar base material, respectively, to investigate the development and controllability of process-induced residual stresses in the clad and to analyse their correlation with microstructural evolutions of the clad and heat-affected zone (HAZ) during cladding and post-heat treatments. The residual stresses were evaluated using the hole-drilling method as per ASTM E837-95, whereas the microstructures were studied using X-ray diffractometer, optical microscope and scanning electron microscope. A particular attention was paid to combined effect of both clad and HAZ on the build-up of residual stresses in the clad. It is expected that the experimental results will form a useful addition to the existing knowledge with respect to the topic and, more significantly, to promote confidence on industrial applications of laser-clad IN-625, Stellite 6 and CPM 10V materials.

Similar content being viewed by others

References

Jensen TA (2001) In: Ready JF, Farson DF (eds) LIA handbook of laser materials processing. LIA/Magnolia Publishing Inc., Orlando, p 284

Steen WM (1998) Laser material processing, 2nd edn. Springer, London, p 248

Vilar R (1999) J Laser Appl 11(2):64

Toyserkani E, Khajepour A, Corbin S (2005) Laser cladding. CRC Press, Boca Raton, p 1

Schubert E, Seefeld T, Rinn A, Sepold G (1999) J Therm Spray Technol 8(4):590

Dubourg L, Archambeault J (2008) Surf Coat Technol 202:5863

Sliva B, Pires I, Quintino L (2008) Mater Sci Forum 587–588:936

Xu G, Kutsuna M, Liu Z, Yamada K (2006) Surf Coat Technol 201:1138

Thompson S (1999) Handbook of mold, tool and die repair welding. William Andrew Publishing, Burlington, p 3

Preciado WT, Bohorquez CEN (2006) J Mater Process Technol 179:244

Champagne VK (2007) In: Champagne VK (ed) The cold spray materials deposition process: fundamentals & applications. Woodhead Publishing Limited, Cambridge, England, p 327

Gnyusov SN, Gnyusov KS, Durakov VG (2008) Weld Int 22(12):863

Bruckner F, Lepski D, Beyer E (2007) J Therm Spray Technol 16(3):355

Lepski D, Bruckner F (2009) In: Dowden J (ed) The theory of laser materials processing: heat and mass transfer in modern technology. Springer, The Netherland, p 235

Chen JY, Xue L, Visscher H, Wolfe J (2009) In: Symposium on surface protection for enhanced material performance in materials science & technology 2009 (MS&T’09), Pittsburgh, p 2090

Dekumbis R (1989) In: Proceedings of 6th conference on lasers in manufacturing, Birmingham, UK, IFS Ltd, p 185

Pei YT, De Hosson JThM (2000) JOM-e 52(1). http://www.tms.org/pubs/journals/JOM/0001/Pei/Pei-0001.html

Inoue T (2005) In: Feng Z (ed) Processes and mechanisms of welding residual stress and distortion. Woodhead Publishing Ltd., Cambridge, England, p 100

Inoue T (2002) In: Totten G, Howes M, Inoue T (eds) Handbook of residual stresses and deformation of steel. ASM International, Materials Park, p 296

Pilloz M, Pelletier JM, Vannes AB (1992) J Mater Sci 27:1240. doi:10.1007/BF01142030

Dubourg L, Hlawka F, Cornet A (2006) In: Sudarshan TS, Jeandin M, Stiglich JJ (eds) Surface modification technologies XVIII. ASM International, Materials Park, p 331

Chen Y, Liang X, Liu Y, Xu B (2010) Mater Des 31:3852

Pluyette E, Sprauel JM (1994) In: Proceedings of 4th international conference on residual stresses, Baltimore, Maryland, p 860

Grum J, Znidarsic M (2002) Mater Sci Forum 404-407:437

Tuominen J, Vuoristo P, Mantyla T (2005) In: ICALEO 2005, LIA, p 635

De Oliveira U, Ocelik V, De Hosson JThM (2006) Surf Coat Technol 201:533

De Freitas M, Pereira MS, Michaud H, Pantelis D (1993) Mater Sci Eng A 167:115

Sexton L, Lavin S, Byrne G, Kennedy A (2002) J Mater Process Technol 122:63

Deloro Stellite, Stellite® 6 Alloy (Technical Data). www.stellite.com

Frenk A, Henchoz N, Kurz W (1993) Z Metallkd 84(12):886

Crucible Research Service Centre (2003) CRUCIBLE CPM® 10 V® (AISI A11), Issue #7

Hu YP, Chen CW, Mukherjee K (1998) J Mater Sci 33:1287. doi:10.1023/A:1004346214050

Donachie MJ, Donachie SJ (eds) (2002) In: Superalloys: a technical guide. ASM International, Materials Park, p 4

ASTM International (2009) Standard specification for wrought carbon steel wheels (Designation: A 504/A 504M–08)

Bauccio M (ed) (1993) In: ASM metals reference book, 3rd edn. ASM International, Materials Park, p 302

Donachie MJ, Donachie SJ (eds) (2002) In: Superalloys: a technical guide, 2nd edn. ASM International, Materials Park, p 245

Xue L, Theriault A, Chen JY, Islam MU, Wieczorek A, Draper G (2002) In: Srivatsan TS, Varin RA (eds) Processing & fabrication of advanced materials X. ASM International, Materials Park, p 361

Measurements Group, Inc. (1992) Model RS-200 milling guide—instruction manual

Lu J, James MR, Mordfin L (1997) In: Lu J (ed) Handbook of measurement of residual stresses. The Fairmont Press, Inc., Lilburn, p 229

Conlon K, Rogge R, Chen JY, Xue L (2005) Investigation of residual stresses in laser-clad metal plates by neutron diffraction, NRC-SIMS Internal Report

Haynes international, high-temperature alloys data sheet H-3073D: Haynes 625 alloy. http://www.haynesintl.com

D’Oliveira ASCM, Da Silva PSCP, Vilar R (2002) Surf Coat Technol 153:203

Chang SS, Wu HC, Chen C (2008) Mater Manuf Process 23:708

Onink M, Brakman CM, Tichelaar FD, Mettemeijer EJ, Van der Zwaag S, Root JH, Konyer NB (1993) Scripta Metall Mater 29:1011

Blackwood RR, Jarvis LM, Hoffman DG, Totten GE (1998) In: The 18th ASM heat treating society conference & exposition, Rosemont, IL, p 575

Bendeich P, Alam N, Brandt M, Carr D, Short K, Blevins R, Curfs C, Kirstein O, Atkinson G, Holden T, Rogge R (2006) Mater Sci Eng A 437:70

Zinn W, Scholtes B (2002) In: Totten GE, Howes M, Inoue T (eds) Handbook of residual stresses and deformation of steel. ASM International, Materials Park, p 391

Costa L, Vilar R, Reti T, Colaço R, Deus AM, Felde I (2005) Mater Sci Forum 473–474:315

Costa L, Reti T, Deus AM, Vilar R (2002) In: Keicher D, Sears JW, Smugeresky JE (eds) Proceedings of international conference on metal powder deposition for rapid manufacturing, MPIF, Princeton, NJ, p 172

Vilar R, Colaço R, Almeida A (1995) Opt Quant Electron 27:1273

Wang SH, Chen JY, Xue L (2006) Surf Coat Technol 200:3446

Leunda J, Soriano C, Sanz C, García Navas V (2011) Physics Procedia 12:345

Kusy M, Caplovic L, Grgac P, Vyrostkova A (2004) J Mater Process Technol 157–158:729

Kusy M, Grgac P, Behulova M, Vyrostkova A, Miglierini M (2004) Mater Sci Eng A 375–377:599

Boccalini M, Goldenstein H (2001) Int Mater Rev 46(2):92

Colaço R, Vilar R (1998) J Mater Sci Lett 17:563

Colaço R, Vilar R (2004) Mater Sci Eng A 385:123

Hemmati I, Ocelík V, De Hosson JThM (2011) J Mater Sci 46:3405. doi:10.1007/s10853-010-5229-2

Linde group, white paper: sub-zero treatment: technology, processes and equipment, 1st Sept. 2010, Germany. www.linde-gas.com

Acknowledgements

Authors would like to thank J. Fenner, A. Chen and M. Meinert (NRC-IMI-London) for their important contributions on the preparation and metallurgical characterization of the clad specimens. Authors highly appreciated critical comments and suggestions from the paper’s reviewers as well, which were beneficial to the improvement of discussion in this article.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, J., Wang, SH. & Xue, L. On the development of microstructures and residual stresses during laser cladding and post-heat treatments. J Mater Sci 47, 779–792 (2012). https://doi.org/10.1007/s10853-011-5854-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5854-4