Abstract

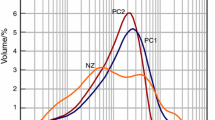

Hardening behaviour and strength of oxychloride cement strongly depend on the formation of Phase 3 and Phase 5 from MgO and magnesium chloride water solution, and the initial composition can be chosen accordingly within the corresponding phase diagram. A certain number of reactions occur before the final formation of P5 or P3 crystals, and several parameters influence the transformations kinetic, such as MgO reactivity and temperature. Several articles deal with the first aspect, while no indications can be found with regard to the curing temperature’s effect on the formation of noble phases. In this article the evolution of magnesium oxychloride cement pastes is analysed at various curing temperatures between 5 and 40 °C. The study is carried out to simulate typical industrial processing conditions and indicate optimal conditions for the production of high chemical and mechanical resistance oxychloride cement. It is shown that at low temperature, Phase 3 is produced in place of Phase 5, and a certain amount of MgO remains non-reacted. The corresponding cement is characterised by lower mechanical strength and higher water solubility.

Similar content being viewed by others

References

Sorel S (1867) C R Acad Sci France 65:102

P de Henau, M Dupas (1976) In Proceedings of the second international symposium on the deterioration of building stone, Athens, p 319

Skoulikidis Th, Papakonstantinou E, Galanos A, Doganis Y (1994) Study for the restoration of the Parthenon, vol 3. Ministry of Culture, Committee for the Preservation of the Acropolis Monuments, Athens

Maravelaki-Kalaitzaki P, Moraitou G (1999) Cem Concr Res 29:1929

Xia S, Xing P, Gao S (1991) Thermochim Acta 183:349

de Castellar MD, Lorente JC, Traveria A, Tura JM (1996) Cem Concr Res 26(8):1199

Plekhanova TA, Keriene J, Gailius A, Yakovlev GI (2007) Constr Build Mater 21:1833

Hassan SSM, Awwad NS, Aboterika AHA (2006) J Radioanal Nucl Chem 269(1):135

Awwad NS, Daifullah AAM (2005) J Radioanal Nucl Chem 264(3):623

Sorrell CA, Armstrong CR (1976) J Am Ceram Soc 59(1–2):51

Matkovic B, Young IF (1973) Phys Sci 246:79

Matkovic B, Popovic S, Rogic V, Zunic T, Young JF (1977) J Am Ceram Soc 60(11–12):504

Li Z, Chau CK (2007) Cem Concr Res 37:866

Urwongse L, Sorrell CA (1980) J Am Ceram Soc 63(9–10):501

Cole WF, Demediuk T (1955) Aust J Chem 8(2):234

Bilinski H, Matkovic B, Mazuranic C, Zunic TB (1984) J Am Ceram Soc 67(4):266

Dehua D, Chuanmei Z (1999) Cem Concr Res 29:1365

Lutterotti L, Ceccato R, Dal Maschio R, Pagani E (1998) Mater Sci Forum 278–281:87

Lutterotti L, Bortolotti M, Ischia G, Lonardelli I, Wenk H-R (2007) Z Kristallogr Suppl 26:125

Shetty DK, Rosenfield AR, McGuire P, Bansal GK, Duckworth WH (1980) Ceram Bull 59(12):1193

JCPDS – Joint Committee on Powder Diffraction Standards – PDF Powder Diffraction File

ICSD Collection Code – available on Crystallography Open Database (COD). https://doi.org/www.crystallography.net

Acknowledgements

The authors thank Deroma Spa for their financial support. The authors thank also Dr. Andrea Camporese and Dr. Marco Passerini (Ricert srl, Monte di Malo , VI, Italy) for their helpful discussions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sglavo, V.M., De Genua, F., Conci, A. et al. Influence of curing temperature on the evolution of magnesium oxychloride cement. J Mater Sci 46, 6726–6733 (2011). https://doi.org/10.1007/s10853-011-5628-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5628-z