Abstract

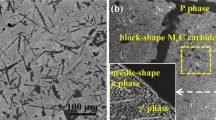

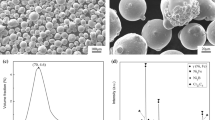

A study of the microstructure, development of contact resistance during oxidation, and abrasive wear behavior for a Ni–18 at.%Ru alloy is presented in this article. It is shown that the alloy can be solutionized and aged, resulting in a fine lamellar mixture of FCC α-Ni and HCP β-Ru phases. Upon oxidation in air for 400 h, the measured contact resistance of the alloy is two orders of magnitude lower than that of pure Ni after 400-h oxidation. This behavior results from the formation of a low-resistivity rutile RuO2 scale on the β phase lamellae, which gives conducting pathways through the insulating NiO scale that forms on the α phase. After an initial run-in period, the steady-state abrasive wear rate measured for the Ni–Ru alloy is an order of magnitude less than that of pure Ni. Since the micro-cutting and flaking wear mechanisms are the same, the differences in the wear rates are ascribed to the presence of the well-dispersed hard Ru-rich β phase. The combination of a low-resistivity self-healing native oxide scale and good wear properties makes the alloy an excellent candidate for electrical contact applications.

Similar content being viewed by others

References

Holm R (1967) Electric contacts: theory and applications. Springer-Verlag, Berlin

Slade PG (ed) (1999) Electrical contacts: principles and applications. CRC Press, Boca Raton

Braunovic M, Myshkin NK, Konchits VV (2006) Electrical contacts: fundamentals, applications and technology. CRC Press, Boca Raton

Antler M (1985) Wear 106:5–33

Beloufa A (2010) Tribol Int 43:2110–2119

Kim K (2010) Wear 269:655–663

Aindow M, Alpay SP, Liu Y, Mantese JV, Senturk BS (2010) Appl Phys Lett 97:152103

Tsuda N, Nasu K, Fujimori A, Siratori K (2000) Electronic conduction in oxides, 2nd edn. Springer, New York

Keith MG, James RC (1993) Phys Rev B 47:1732

Mattheiss LF (1976) Phys Rev B 13:2433

Graebner JE, Greiner ES, Ryden WD (1976) Phys Rev B 13:2426

Boshta M, Gad SA, El-Soud AMA, Mostafaa MZ (2009) J Ovonic Res 5:1–8

Jang WL, Lu YM, Hwang WS, Chen WC (2010) J Eur Ceram Soc 30:503–508

Hakim A, Hossain J, Khan KA (2009) Renew Energ 34:2625–2629

ASTM Standard B 667-97, Standard Practice for Construction and Use of a Probe for Measuring Electrical Contact Resistance, 1997

Tamai T (1989) Electron Commun Jpn Part 2. Electron 72:87–93

Zhu YF, Mimira K, Lim J, Isshiki M, Jiang Q (2006) Met Mater Trans A 37A:1231–1237

Veeka Kumari S, Natarajan M, Vaidyan VK (1992) J Mater Sci Lett 11:761–762

Chang C, Wang C, Jin Y (2010) Wear 29:167–173

Suh NP (1973) Wear 25:111–124

Suh NP (1977) Wear 44:1–15

Gui MC, Kang SB, Lee JM (2000) J Mater Sci 35:4749–4762

Gialanella S, Ischia G, Straffelini G (2008) J Mater Sci 43:1701–1710

Al-Qutub AM, Allam IM, Samad MAA (2008) J Mater Sci 43:5797–5803

Kumari UR, Rao PP (2009) J Mater Sci 44:1082–1093

Zhao YT, Wang SQ, Yang ZR, Wei MX (2010) J Mater Sci 45:227–232

Savaskan T, Bican O, Alemdag Y (2009) J Mater Sci 44:1969–1976

Srivastava VC, Rudrakshi GB, Uhlenwinkel V, Ojha SN (2009) J Mater Sci 44:2288–2299

Yan SQ, Xie JP, Liu ZX, Li JW, Wang WY, Wang AQ (2009) J Mater Sci 44:4169–4173

Acknowledgements

The authors gratefully acknowledge the support extended by the U. S. Army Research Office through Grant No. W-911-NF0710388.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Y., Senturk, B.S., Mantese, J.V. et al. Electrical and tribological properties of a Ni–18%Ru alloy for contact applications. J Mater Sci 46, 6563–6570 (2011). https://doi.org/10.1007/s10853-011-5603-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5603-8