Abstract

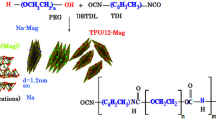

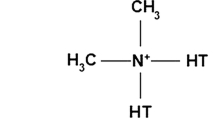

Thermoplastic polyurethane (TPU)/organoclay nanocomposites are prepared through a melt extrusion process. The TPU is combined with four differently modified organoclays, namely, I.28E, I.30P, I.34TCN, and I.44P. Wide-angle X-ray diffraction and transmission electron microscopy results show that the addition of I.34TCN and I.30P to TPU/organoclay nanocomposites results in the nearly exfoliated structures of the nanocomposites. Addition of I.28E leads to partially intercalated nanocomposites, whereas I.44P cannot disperse effectively in the nanocomposites. Organoclay can enhance the mechanical and gas barrier properties of TPU. The enhancement follows the order TPU/I.34TCN ≥ TPU/I.30P > TPU/I.28E > TPU/I.44P, which is consistent with the degree of dispersion and exfoliation of silicate layers. In addition, Fourier transform infrared absorption spectra show that more hydrogen bonding sites are introduced between the clay modifiers and TPU chains in the TPU/I.34TCN and TPU/I.30P nanocomposites; this has a positive impact on the dispersion of the organoclay and, consequently, the mechanical and gas barrier properties of the nanocomposites.

Similar content being viewed by others

References

Kawasumi M, Hasegawa N, Kato M, Usuki A, Okada A (1997) Macromolecules 30:6333

Usuki A, Kojima Y, Kawasumi M et al (1993) J Mater Res 8:1179

Zhong Y, Zhu ZY, Wang SQ (2005) Polymer 46:3006. doi:https://doi.org/10.1016/j.polymer.2005.02.014

Chang JH, An YU, Sur GS (2003) J Polym Sci B Polym Phys 41:94. doi:https://doi.org/10.1002/polb.10349

Jeong HM, Kim BC, Kim EH (2005) J Mater Sci 40:3783. doi:https://doi.org/10.1007/s10853-005-3719-4

Zhang YD, Liu QF, Zhang QA, Lu YP (2010) Appl Clay Sci 50:255. doi:https://doi.org/10.1016/j.clay.2010.08.006

Oral A, Tasdelen MA, Demirel AL, Yagci Y (2009) Polymer 50:3905. doi:https://doi.org/10.1016/j.polymer.2009.06.020

Ramazani SAA, Tavakolzadeh F, Baniasadi H (2010) J Appl Polym Sci 115:308. doi:https://doi.org/10.1002/app.31102

Ren CY, Jiang ZY, Du XH, Men YF, Tang T (2009) J Phys Chem B 113:14118. doi:https://doi.org/10.1021/jp9063164

Ray SS, Okamoto M (2003) Prog Polym Sci 28:1539. doi:https://doi.org/10.1016/j.progpolymsci.2003.08.002

Zha WB, Han CD, Han SH et al (2009) Polymer 50:2411. doi:https://doi.org/10.1016/j.polymer.2009.03.018

Yang M, Wang P, Huang CY, Ku MS, Liu HJ, Gogos C (2010) Int J Pharm 395:53. doi:https://doi.org/10.1016/j.ijpharm.2010.04.033

Simons R, Qiao GG, Powell CE, Bateman SA (2010) Langmuir 26:9023. doi:https://doi.org/10.1021/la904827d

Tian Y, Yu H, Wu SS, Ji GD (2004) J Mater Sci 39:4301. doi:https://doi.org/10.1023/B:JMSC.0000033412.92494.ee

Lakshminarayanan S, Lin B, Gelves GA, Sundararaj U (2009) J Appl Polym Sci 112:3597. doi:https://doi.org/10.1002/app.29679

Krishnamoorti R, Vaia RA, Giannelis EP (1996) Chem Mater 8:1728

Giannelis EP (1996) Adv Mater 8:29

Wang Z, Pinnavaia TJ (1998) Chem Mater 10:3769

Tien YI, Wei KH (2001) Macromolecules 34:9045. doi:https://doi.org/10.1021/ma010551p

Cai YB, Hu Y, Song L et al (2007) J Mater Sci 42:5785. doi:https://doi.org/10.1007/s10853-006-0634-2

Pegoretti A, Dorigato A, Brugnara M, Penati A (2008) Eur Polym J 44:1662. doi:https://doi.org/10.1016/j.eurpolymj.2008.04.011

Dan CH, Kim YD, Lee MH, Min BH, Kim JH (2008) J Appl Polym Sci 108:2128. doi:https://doi.org/10.1002/app.27879

Dan CH, Lee MH, Kim YD, Min BH, Kim JH (2006) Polymer 47:6718. doi:https://doi.org/10.1016/j.polymer.2006.07.052

Cipriano BH, Kota AK, Gershon AL et al (2008) Polymer 49:4846. doi:https://doi.org/10.1016/j.polymer.2008.08.057

Calcagno CIW, Mariani CM, Teixeira SR, Mauler RS (2007) Polymer 48:966. doi:https://doi.org/10.1016/j.polymer.2006.12.044

Lee MH, Dan CH, Kim JH et al (2006) Polymer 47:4359. doi:https://doi.org/10.1016/j.polymer.2006.04.003

Jia QM, Zheng M, Zhu YC, Li JB, Xu CZ (2007) Eur Polym J 43:35. doi:https://doi.org/10.1016/j.eurpolymj.2006.10.016

Balazs AC, Singh C, Zhulina E (1998) Macromolecules 31:8370

Lyatskaya Y, Balazs AC (1998) Macromolecules 31:6676

Worzakowska M (2009) J Mater Sci 44:4069. doi:https://doi.org/10.1007/s10853-009-3587-4

Meng XY, Wang Z, Zhao ZF, Du XH, WG Bi, Tang T (2007) Polymer 48:2508. doi:https://doi.org/10.1016/j.polymer.2007.03.009

Nielsen LE (1967) J Macromol Sci Chem A1:929

Lan T, Kaviratna PD, Pinnavaia TJ (1994) Chem Mater 6:573

Chen BQ, Evans JRG (2006) Macromolecules 39:747. doi:https://doi.org/10.1021/ma052154a

Chang JH, An YU, Cho DH, Giannelis EP (2003) Polymer 44:3715. doi:https://doi.org/10.1016/s0032-3861(03)00276-3

Osman MA, Mittal V, Morbidelli M, Suter UW (2003) Macromolecules 36:9851. doi:https://doi.org/10.1021/ma035077x

Pattanayak A, Jana SC (2005) Polymer 46:5183. doi:https://doi.org/10.1016/j.polymer.2005.04.035

Pattanayak A, Jana SC (2005) Polymer 46:3275. doi:https://doi.org/10.1016/j.polymer.2005.02.081

Kim W, Chung DW, Kim JH (2008) J Appl Polym Sci 110:3209. doi:https://doi.org/10.1002/app.28929

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sheng, D., Tan, J., Liu, X. et al. Effect of organoclay with various organic modifiers on the morphological, mechanical, and gas barrier properties of thermoplastic polyurethane/organoclay nanocomposites. J Mater Sci 46, 6508–6517 (2011). https://doi.org/10.1007/s10853-011-5597-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5597-2