Abstract

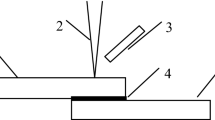

Laser weld bonding is a new welding technology, being used to join Mg–Al alloys. The penetration depth of LWB Mg–Al joint was larger than that in simply laser welding joint in same welding parameters. The temperature at the edge of the Al fusion zone in LWB Mg–Al joint was higher than that in laser welding joint, which was measured through the thermal couples. The laser-introduced plasma in LWB Mg–Al process is observed by the high-speed camera, which is different from that in laser welding process. The surface temperature and state of the Al alloy were changed because of the addition of the adhesive, thus the laser absorptive of Al alloy was increased in LWB process, comparing with that in laser welding process; and the decomposition of the adhesive would make a depression in the Al fusion zone, which would be beneficial to the formation of keyhole welding in LWB Mg–Al joint.

Similar content being viewed by others

References

Zhao H, White DR, DebRoy T (1999) Int Mater Rev 44:238–266

Hekmat-Ardakan A, Ajersch F, Chen X-G (2011) J Mater Sci 46:2370. doi:https://doi.org/10.1007/s10853-010-5084-1

Braun R (2006) Mater Sci Eng A 426:250

Song G, Luo Z (2011) Opt Laser Eng 49:82

Hakamada M, Shimizu K, Yamashita T, Watazu A, Saito N et al (2010) J Mater Sci 45:719. doi:https://doi.org/10.1007/s10853-009-3990-x

Qi X, Gang S (2010) Mater Des 31:605

Vaidya WV, Horstmann M, Ventzke V, Petrovski B, Koçak M et al (2010) J Mater Sci 45:6242. doi:https://doi.org/10.1007/s10853-010-4719-6

Somasekharan AC, Murr LE (2004) Mater Charact 52:49

Yan J, Xu Z (2005) Scr Mater 53:585

Jiang JB, Zhang ZD (2008) J Alloys Compd 466:368

Dietrich D, Nickel D, Krause M, Lampke T, Coleman MP et al (2011) J Mater Sci 46:357. doi:https://doi.org/10.1007/s10853-010-4841-5

Sato YS, Park SHC, Michiuchi M, Kokawa H (2004) Scr Mater 50:1233

Zhao LM, Zhang ZD (2008) Scr Mater 58:283

Chen YC, Nakata K (2008) Scr Mater 58:433

Liu L-M, Wang H-Y, Zhang Z-D (2007) Scr Mater 56:473

Liu L, Wang H, Song G, Ye J (2007) J Mater Sci 42:565. doi:https://doi.org/10.1007/s10853-006-1068-6

Messler RW (2002) Ind Robot 29:138

Mackwood AP, Craferb RC (2005) Opt Laser Technol 37:99

Anisimov SI, Khokhlov VA (1996) Instabilities in laser–matter interaction. CRC, Boca Raton

Landau LD, Lifshitz EM (1980) Statistical physics, part I. Pergamon, Oxford

Semak V, Matsunawa A (1997) J Phys D Appl Phys 30:2541

Acknowledgements

The authors really appreciate the supports from National Natural Science Funds for Distinguished Young Scholar (51025520) and Fundamental Research Funds for the Central Universities (DUT10ZD108).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, H.Y., Liu, L.M. & Jia, Z.Y. The influence of adhesive on the Al alloy in laser weld bonding Mg–Al process. J Mater Sci 46, 5534–5540 (2011). https://doi.org/10.1007/s10853-011-5498-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5498-4