Abstract

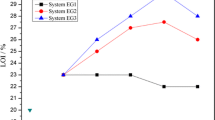

Medium-density foam composites based on silica fibre-filled phenolic syntactic foams were processed and characterised for mechanical, dynamic mechanical and thermophysical properties, and they were evaluated as Thermal Protection Systems (TPSs) materials by way of experiment and simulated thermal response studies under atmospheric re-entry conditions. Ablative composites with different specific gravities were processed by varying the volume fraction of the constituents. Tensile strength increased with fibre concentration and showed a maximum corresponding to 15% by volume of silica fibre and decreased on further addition, whereas flexural and compressive strength increased with increase in volume percentage of silica fibre. The mechanical properties of the fibre reinforced system were superior compared to those of bare phenolic syntactic foams. Storage modulus was considerably improved by the addition of fibre whilst the glass transition temperature was unaffected. The compositional dependency of the ablative composites on their thermophysical properties and thermal degradation behaviour was also examined. The thermal response of the ablatives was studied by simulating a moderate atmospheric re-entry heat flux history on the specimen with a maximum heat flux of about 15–18% of the stagnation heating. The thermal response was measured, and the material surface behaviour, mass loss and flammability were studied. For fibre fractions corresponding to various specific gravities, the thermal simulation experiments were studied, and it was observed that the char strength and its structural integrity were satisfactory for a specific gravity of 0.5. The maximum backwall temperature measured was 110 °C for a test duration of 500 s, and this meets the structural temperature constraint of 150 °C at the interface. The thermal response was numerically modelled, and fairly good comparison was obtained with the experimental results. This validated the accuracy of the measurement of the thermophysical properties and delivered the medium-density ablative TPS system qualified for application in atmospheric re-entry.

Similar content being viewed by others

References

Bahramian AR, Kokabi M, Famili MHN, Beheshty MH (2006) Polymer 47:3661

John B, Nair CPR, Ninan KN (2007) Cell Polym 26:229

John B, Nair CPR (2010) Update on syntactic foams. iSmithers Rapra, UK

Okuno K, Woodhams RT (1974) J Cell Plast 10:237

Sunshine N (1973) In: Kuryla W, Papa J (eds) Flame retardancy of phenolic materials. Marcel Dekker, New York

Sreejith PS, Krishnamurthy R, Malhotra SK, Narayanasamy K (2000) J Mater Process Technol 104:53

Re-entry Technology: Atmospheric Re-entry Demonstrator, European Space Agency, Directorate of Manned Spaceflight and Microgravity. https://doi.org/www.estec.esa.nl/spaceflight/index.htm

Guthrie JD, Battat B, Severin BK. Advanced materials and process technology. Defense Technical Information Centre, IIT Research Institute, New York. https://doi.org/www.amptiac.iitri.org

Torre L, Kenny JM, Boghetich G, Maffezzoli A (2000) J Mater Sci 35:4563. doi:https://doi.org/10.1023/A:1004828923152

Gupta N, Karthikeyan CS, Sankaran S, Kishore (1999) Mater Charact 43:271

Karthikeyan CS, Sankaran S, Kishore (2005) Macromol Mater Eng 290:60

Karthikeyan CS, Sankaran S, Kishore (2004) Mater Lett 58:995

John B, Nair CPR, Ninan KN (2008) Polym Polym Compos 16:431

Kumar SK, Krishnamoorthy S, Rao SVS (2006) In: 9th AIAA/ASME joint thermophysics and heat transfer conference, San Francisco, California, 5–8 June 2006

John B, Nair CPR, Devi KA, Ninan KN (2007) J Mater Sci 42:5398. doi:https://doi.org/10.1007/s10853-006-0778-0

Karthikeyan CS, Sankaran S, Kishore (2000) Polym Int 49:158

Joseph PV, Mathew G, Joseph K, Groeninckx G, Thomas S (2003) Compos A Appl Sci Manuf 34:275

Joseph PV, Joseph K, Thomas S (1999) Compos Sci Technol 59:1625

Yu XB, Wei C, Zhang FA (2006) Polym Adv Technol 17:534

Sankaran S, Sekhar KR, Raju G, Kumar MNJ (2006) J Mater Sci 41:4041. doi:https://doi.org/10.1007/s10853-006-7607-3

Agarwal R, Saxena NS, Sharma KB, Thomas S, Pothan LA (2003) Indian J Pure Appl Phys 41:448

Idicula M, Boudenne A, Umadevi L, Ibos L, Candau Y, Thomas S (2006) Compos Sci Technol 66:2719

Acknowledgements

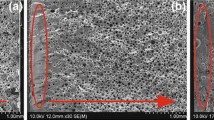

The authors acknowledge Director, VSSC for granting permission to publish this article. Dr. K. Ambika Devi and Dr. Korah Bina Catherine (ASD) are acknowledged for mechanical testing and thermal analysis, respectively. Shri. S. Krishnamoorthy (PRG) is acknowledged for the thermal conductivity measurements and Shri. Ramesh Narayanan (MCD) for SEM analysis. Credit is also due to Shri TV Radhakrishnan, Shri Sundar B, Shri S Jeyarajan and Smt K Vanitha of AHTD for design and test support during the aero-thermal studies.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

John, B., Mathew, D., Deependran, B. et al. Medium-density ablative composites: processing, characterisation and thermal response under moderate atmospheric re-entry heating conditions. J Mater Sci 46, 5017–5028 (2011). https://doi.org/10.1007/s10853-011-5422-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5422-y