Abstract

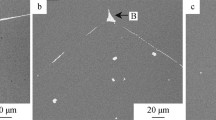

As well known, bismuth rapidly penetrates into copper grain boundaries at about 550 °C and embrittles copper. In the experiments, the authors have used solid Bi2Te3 for the embrittlement of pure copper and copper-based solid solutions containing iron and silver. The investigated alloys were heated in the closed volume together with Bi2Te3 for a short time (5–90 min) at 570 °C in the hydrogen atmosphere. Bi2Te3 did not contact with copper samples during annealing. After that, the samples were bent and grain boundary cracks were formed (with the depth about 10–500 μm). Experiment showed that silver accelerates the embrittlement in the contrast to iron. The cracks in the silver–copper alloys were deeper than in the iron–copper ones. It was assumed that the depth of cracks is equal to the penetration depth. The reasons for this phenomenon were discussed in terms of the impurities effect on the grain boundary segregation.

Similar content being viewed by others

References

Nicholas MG, Old CF (1979) J Mater Sci 14:1. doi:10.1007/BF01028323

Glikman EE, Goryunov YV, Ledovskaya IY (1979) Sov Mater Sci 15:446

Joseph B, Barbier F, Dagoury G, Aucouturier M (1998) Scr Mater 39:775

Joseph B, Barbier F, Aucouturier M (1999) Scr Mater 40:893

Marie N, Wolski K, Biscondi M (2000) Scr Mater 43:943

Marie N, Wolski K, Biscondi M (2001) J Nucl Mater 296:282

Wolski K, Laporte V (2008) Mater Sci Eng A 495:138

Bokstein BS, Klinger LM, Apikhtina IV (1995) Mater Sci Eng A 203:373

Zhevnenko SN, Vaganov DV, Gershman EI (2010) Def Dif Forum 301:439

Divinski S, Lohmann M, Herzig C (2004) Acta Mater 52:3973

Straumal BB, Baretzky B, Kogtenkova OA, Straumal AB, Sidorenko AS (2010) J Mater Sci 45:2057. doi:10.1007/s10853-009-4014-6

Straumal BB, Kogtenkova OA, Straumal AB, Kuchyeyev YuO, Baretzky B (2010) J Mater Sci 45:4271. doi:10.1007/s10853-010-4377-8

Baram M, Kaplan DW (2006) J Mater Sci 41:7775. doi:10.1007/s10853-006-0897-7

Gale WF, Totemeier TC (eds) (2004) Smithells metals reference book, 8th edn. Elsevier, Amsterdam

Ludwig W, Bellet D (2000) Mater Sci Eng A 281:198

Ludwig W, Pereiro-López E, Bellet D (2005) Acta Mater 53:151

Hugo RC, Hoagland RG (2000) Acta Mater 48:1949

Rabkin EI, Semenov VN, Shvindlerman LS, Straumal BB (1991) Acta Metall Mater 39:627

Gupta D (2003) Interface Sci 11:7

Menyhard M, Min Yan, Vitek V (1994) Acta Metall Mater 42:2783

Divinski S, Lohmann M, Herzig C (2001) Acta Mater 49:249

Monzen R, Echigo T (1999) Scr Mater 40:963

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhevnenko, S.N., Vaganov, D.V. & Gershman, E.I. Rapid penetration of bismuth from solid Bi2Te3 along grain boundaries in Cu and Cu-based alloys. J Mater Sci 46, 4248–4253 (2011). https://doi.org/10.1007/s10853-010-5234-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-5234-5