Abstract

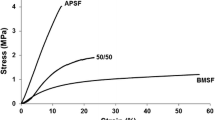

Theriodopteryx ephemeraeformis commonly known as bag worms produce ultrafine silk fibers that are remarkably different than the common domesticated (Bombyx mori) and wild (Saturniidae) silk fibers. Bag worms are considered as pests and commonly infect trees and shrubs. Although it has been known that the cocoons (bags) produced by bag worms are composed of silk, the structure and properties of the silk fibers in the bag worm cocoons have not been studied. In this research, the composition, morphology, physical structure, thermal stability, and tensile properties of silk fibers produced by bag worms were studied. Bag worm silk fibers have considerably different amino acid contents from those of the common silks. The physical structure of the bag worm silk fibers is also considerably different compared with B. mori and common wild silk fibers. Bag worm’s silk fibers have lower tensile strength (3.2 g/denier) and Young’s modulus (45 g/denier) but similar breaking elongation (15.3%) compared with B. mori silk. However, the tensile strength and Young’s modulus of bag worm fibers are similar to those of the common Saturniidae wild silk fibers. Bag worm silk fibers could be useful for some of the applications currently using the B. mori and wild silk fibers.

Similar content being viewed by others

References

Robson RM (1998) In: Lewin M, Pearce EM (eds) Handbook of fiber chemistry. Marcel Dekker Inc, New York

Sen K, Babu MK (2004) J Appl Polym Sci 92:1080

Sen K, Babu MK (2004) J Appl Polym Sci 92:1098

Kameda T, Tsukada M (2006) Macromol Mater Eng 291:877

Acharya C C, Ghosh SK, Kundu SC (2009) Acta Biomater 5(1):429

Kearns V, MacIntosh AC, Crawford A, Hatton PV (2008) Top Tissue Eng 4:1

Takeshita H, Ishida K, Kamiishi Y, Yoshii F, Kume T (2008) Macromol Mater Eng 283:126

Kakati LN, Chutia BC (2009) Trop Ecol 50(1):137

Razafimanantosoa T, Ravoahangimalala OR, Craig CL (2006) Madag Conserv Dev 1(1):34

Acharya C, Ghosh SK, Kundu SC (2008) J Mater Sci Mater Med 19:2827

Reddy N, Yang Y (2010) Int J Biol Macromol 46(4):419

Sutherland TD, Weisman S, Trueman HE, Sriskantha A, Trueman JWH, Haritos VS (2007) Mol Biol Evol 24(11):2424

Brown SA, Ruxton GD, Humphries A (2004) J N Am Benthol Soc 23(4):771

Saravanan D (2006) J Text Appar Technol Manag 5(1):1

Rhainds M, Davis DR, Price PW (2009) Annu Rev Entomol 54:209

Weiss HB (1914) Psyche 21(1):45

Bhat NV, Nadiger GS (1980) J Appl Polym Sci 25:921

Perez-Rigueiro J, Elices M, LLoraca J, Viney C (2001) J Appl Polym Sci 82:53

Rajkhowa R, Gupta VB, Kothari VK (2000) J Appl Polym Sci 77:2418

Shaw JTB, Smith SG (1961) Biochem Biophys Acta 52:305

Craig CL, Hsu H, Kaplan D, Pierce NE (1999) Int J Biol Macromol 24:109

Warwicker JO (1960) J Mol Biol 2:350

Zhou C, Confalonieri F, Jacquet M, Perasso R, Li Z, Janin J (2001) Proteins Struct Funct Bioinf 44:119

Gage LP, Manning RF (1980) J Biol Chem 255(19):9444

Lotz B, Cesari C (1979) Biochemie 61:205

Zhao C, Yao J, Masuda H, Kishore R, Asakura T (2003) Biopolymers 69:253

Dobb MG, Frazer RDB, Macrae TP (1967) J Cell Biol 32:289

Acknowledgements

The authors acknowledge the financial support from the Agricultural Research Division at the University of Nebraska-Lincoln, USDA Hatch Act and Multi-State Project S1026 for completing this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Reddy, N., Yang, Y. Structure and properties of ultrafine silk fibers produced by Theriodopteryx ephemeraeformis . J Mater Sci 45, 6617–6622 (2010). https://doi.org/10.1007/s10853-010-4752-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4752-5