Abstract

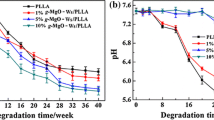

In this article, mesoporous 58S and 58S bioactive glasses (BGs) were surface modified by dodecyl alcohol through esterification reaction and PDLLA/modified BGs composite films were prepared. The purpose of this study was to investigate the properties of the modified BGs particles and the PDLLA/modified BGs composite films before and after hydrolytic treatment. The modified BGs powders and composite films were treated in boiling water for 20 min to remove the dodecyl chains. After hydrolytic treatment, the modified BGs powders showed increased hydrophilicity and the FTIR analysis revealed that most dodecyl chains were removed. Furthermore, the hydrophilicity of the PDLLA/modified BGs composite films was also greatly improved. The tensile strength of the composite films after hydrolysis decreased slightly, but was still much higher than that of pure PDLLA film. In addition, bone marrow mesenchymal stem cells from dogs on the composite films after hydrolytic treatment showed the highest proliferation rate. The results suggest that hydrolytic treatment is an effective and practicable method to remove alcohol chains from surface-modified BGs and polymers/modified BG composites, which may be used for preparation of bioactive scaffolds for tissue engineering applications.

Similar content being viewed by others

References

Hench LL (1991) J Am Ceram Soc 74:1487

Hench LL, Polak JM (2002) Science 295:1014

Hench LL, West KJ (1990) Chem Rev 90:33

Saravanapavan P, Hench LL (2003) J Non-Cyst Solids 318:1

Vallet-Regi M, Ragel CV, Salinas AJ (2003) Eur J Inorg Chem 1029

Yan XX, Yu CZ, Zhou XF, Tang JW, Zhao DY (2004) Angew Chem Int Ed 43:5980

Rich J, Jaakkola T, Tirri T, Narhi T, Yli-Urpo A, Seppala J (2002) Biomaterials 23:2143

Misra SK, Mohn D, Brunner TJ, Stark WJ, Philip SE, Roy I, Salih V, Knowles JC, Boccaccini AR (2008) Biomaterials 29:1750

Maquet V, Boccaccini AR, Pravata L, Notingher I, Jerome R (2004) Biomaterials 25:4185

Jiang G, Evans ME, Jones IA, Rudd CD, Scotchford CA, Walker GS (2005) Biomaterials 26:2281

Silva GA, Costa FJ, Coutinho OP, Radin S, Ducheyne P, Reis RL (2004) J Biomed Mater Res A 70A:442

Verrier S, Blaker JJ, Maquet V, Hench LL, Boccaccini AR (2004) Biomaterials 25:3013

Lo H, Kadiyala S, Guggino SE, Leong KW (1996) J Biomed Mater Res 30:475

Stamboulis A, Hench LL, Boccaccini AR (2002) J Mater Sci Mater Med 13:843

Yao J, Radin S, Leboy PS, Ducheyne P (2005) Biomaterials 26:1935

Maquet V, Boccaccini AR, Pravata L, Notingher I, Jerome R (2003) J Biomed Mater Res A 66A:335

Hong ZK, Zhang PB, He CL, Qiu XY, Liu AX, Chen L, Chen XS, Jing XB (2005) Biomaterials 26:6296

Supova M (2009) J Mater Sci Mater Med 20:1201

Zhang SM, Liu J, Zhou W, Cheng L, Guo XD (2005) Curr Appl Phys 5:516

Cheng W, Chang J (2006) J Biomater Appl 20:361

Borum-Nicholas L, Wilson OC (2003) Biomaterials 24:3671

Liu AX, Hong ZK, Zhuang XL, Chen XS, Cui Y, Liu Y, Jing XB (2008) Acta Biomater 4:1005

Gao Y, Chang J (2009) J Biomater Appl 24:119

Steele JG, McFarland C, Dalton BA, Johnson G, Evans MDM, Howlett CR, Underwood PA (1993) J Biomater Sci Polym Ed 5:245

Ballard CC, Broge EC, McWhorter JR, Iler RK, Stjohn DS (1961) J Phys Chem 65:20

Zhong JP, Greenspan DC (2000) J Biomed Mater Res 53:694

Xia W, Chang J (2006) J Controlled Release 110:522

Ringe J, Kaps C, Schmitt B, Buscher K, Bartel J, Smolian H et al (2002) Cell Tissue Res 307:321

Dufrane D, Delloye C, McKay IJ, De Aza PN, De Aza S, Schneider YJ, Schultz O, Burmester GR, Haupl T, Sittinger M (2003) J Mater Sci Mater Med 14:33

Ossenkamp GC, Kemmitt T, Johnston JH (2002) Langmuir 18:5749

Arcos D, Greenspan DC, Vallet-Regi M (2003) J Biomed Mater Res A 65A:344

Hiroshi Utsugi HH, Matsuzawa T (1975) J Colloid Interface Sci 50:154

Anselme K (2000) Biomaterials 21:667

Verrier S, Bareille R, Rovira A, Dard M, Amedee J (1996) J Mater Sci Mater Med 7:46

Yang M, Zhu SS, Chen Y, Chang ZJ, Chen GQ, Gong YD, Zhao NM, Zhang XF (2004) Biomaterials 25:1365

Webb K, Hlady V, Tresco PA (1998) J Biomed Mater Res 41:422

Acknowledgement

This study was financially supported by the National Basic Science Research Program of China (973 Program) (Grant No. 2005CB522704), the Natural Science Foundation of China (Grant No. 30730034), and Science and Technology Commission of Shanghai Municipality (Grant No. 08JC1420800).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, Y., Gao, Y. & Chang, J. Effects of hydrolysis on dodecyl alcohol-modified bioactive glasses and PDLLA/modified bioactive glass composite films. J Mater Sci 45, 6411–6416 (2010). https://doi.org/10.1007/s10853-010-4724-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4724-9