Abstract

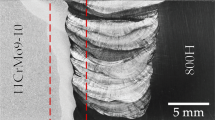

Characterizations of the microstructure and mechanical property of the fusion boundary region of an Alloy 182-A533B low alloy steel (LAS) dissimilar weld joint were conducted. The existence of type-II boundary that parallels to the fusion boundary in the dilution zone (DZ) of Alloy 182 within a distance of about 50 μm was observed. The chemical composition transition was found in the narrow zone between the type-II and the fusion boundaries. Highest hardness was also found in this narrow zone in the fusion boundary region, implying a high residual strain level in the narrow zone. Lath martensite was observed in both sides of the type-II boundary in DZ, suggesting the localized enrichment of Fe and C adjacent to the type-II boundary due to the diffusion from LAS to DZ. Massive precipitations of carbides were observed on the type-II boundary but not on the fusion boundary. In addition, the orientation relationship at the fusion boundary between the lath martensite in the heat-affected zone in LAS and the austenite in the DZ was found to be Bain, K–S and N–W relationships.

Similar content being viewed by others

References

Sireesha M, Albert SK, Shankar V, Sundaresan S (2000) J Nucl Mater 279:65

USNRC In: Information Notice 2000-17, 18 October 2000

USNRC In: Information Notice 2002-11, 12 March 2002

Peng QJ, Shoji T, Yamauchi H, Takeda Y (2007) Corros Sci 49:2767

Sakai T, Asami K, Katsumata M, Takada H, Tanaka O (1982) In: 1st international conference on current solutions to hydrogen problems in steels, Washington DC, pp 340–348

Matsuda F, Nakagawa H (1984) Trans JWRI 13:159

Ohnishi K, Fuji A, Chiba R, Adachi T, Naitoh K, Okada H (1984) Trans Jpn Weld Soc 15:129

Kinoshita K, Itoh H, Ebata A, Hattori T (1985) Trans Iron Steel Inst Jpn 25:505

Morishige N, Kume R, Okabayashi H (1985) Trans Jpn Weld Soc 16:12

Wu Y, Patchett BM (1992) In: 31st metallurgist conference of CIM Edmonton, Canada

Nelson TW, Lippold JC, Mills MJ (1998) Sci Technol Weld Join 3:249

Nelson TW, Lippold JC, Mills MJ (1999) Weld J 78:329S

Nelson TW, Lippold JC, Mills MJ (2000) Weld J 79:267S

Lee HT, Jeng SL, Yen CH, Kuo TY (2004) J Nucl Mater 335:59

Kim JW, Lee K, Kim JS, Byun TS (2009) J Nucl Mater 384:212

Peng Q, Shoji T, Ritter S, Seifert H (2005) In: 12th international conference on environmental degradation of materials in nuclear power systems—water reactors, TMS, pp 589–599

Celik A, Alsaran A (1999) Mater Charact 43:311

Gourgues AF, Flower HM, Lindley TC (2000) Mater Sci Technol 16:26

Morito S, Tanaka H, Konishi R, Furuhara T, Maki T (2003) Acta Mater 51:1789

Chilton JM, Barton CJ, Speich GR (1970) J Iron Steel Inst 208:184

Krauss G, Marder AR (1971) Metall Trans 2:2343

Maki T, Tsuzaki K, Tamura I (1980) Trans Iron Steel Inst Jpn 20:207

Morito S, Yoshida H, Maki T, Huang X (2006) Mater Sci Eng A 438:237

Pan C, Zhang Z (1996) Mater Charact 36:5

Morito S, Huang X, Furuhara T, Maki T, Hansen N (2006) Acta Mater 54:5323

Acknowledgements

This study was supported by a program on “Mechanism of SCC in the Fusion Boundary Zone of Ni-base weld metal and Low Alloy Steel Dissimilar Weld Joints in High Temperature Oxygenated Water” organized by JSCE and sponsored by Japanese BWR utilities. The authors (J. Hou, J. Q. Wang, E.-H. Han, and W. Ke) would thank the Special Funds for the Major State Basic Research Projects G2006CB605000 in China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hou, J., Peng, Q.J., Takeda, Y. et al. Microstructure and mechanical property of the fusion boundary region in an Alloy 182-low alloy steel dissimilar weld joint. J Mater Sci 45, 5332–5338 (2010). https://doi.org/10.1007/s10853-010-4581-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4581-6