Abstract

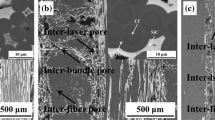

To improve the mechanical properties and oxidation-resistance properties, a C–TaC–C multi-interlayer structure was introduced in carbon/carbon (C/C) composites by chemical vapor infiltration. Compared with conventional C/C composites, a higher fracture toughness and strength have been achieved by using the C–TaC–C multi-interlayer. In addition, the composites also exhibit a higher preliminary oxidation temperature and a lower mass loss at high temperatures. The oxidation rate of the composites increases with temperature increasing in the range of 700–1300 °C, reaching a maximum value at 1300 °C, then decreases in 1300–1400 °C. A hexagonal structure of Ta2O5 phase is obtained when being oxidized at 700–800 °C, and it transforms to an orthorhombic phase at temperatures above 900 °C. The structures of C–TaC–C multi-interlayer are intact without cracks or porosities after being oxidized at 700–800 °C. In 900–1300 °C, the composites are oxidized uniformly with the formation of pores. At temperatures above 1300 °C, there are oxidation and non-oxidation regions with the oxidation process being controlled by diffusion.

Similar content being viewed by others

References

Tang SF, Deng JY, Wang SJ, Liu WC, Yang K (2007) Mater Sci Eng A 465:1

Raman V, Bhatia G, Mishra A, Sengupta PR, Saha M, Rashmi (2005) Mater Sci Eng A 412:31

Virgil’ev YS, Kalyagina IP (2004) Inorg Mater 40:S33

Guo WM, Xiao HN (2007) Carbon 45:1058

Wunder V, Popovska N, Wegner A, Emig G, Arnold A (1998) Surf Coat Technol 100–101:329

Zhu YC, Ohtani S, Sato Y, Iwamoto N (2000) Carbon 38:501

Manocha LM, Manocha S, Patel KB, Glogar P (2000) Carbon 38:1481

Cairo CAA, Florian M, Graca MLA, Bressiani JC (2003) Mater Sci Eng A 358:298

Han JC, He XD, Du SY (1995) Carbon 33:473

Labruquére S, Blanchard H, Pailler R, Naslain R (2002) J Eur Ceram Soc 22:1011

Fiber interface coatings (2009-10-22) US Ultramet. http://www.ultramet.com/fiber_interface_coatings.html. Accessed 2009

Yang WB, Zhang LT, Liu YS, Cheng LF, Zhang WH (2007) Appl Compos Mater 14:277

Lu GF, Qiao SR, Zhang CY, Hou JT, Jia DC, Zhang YB (2008) Compos Part A 39:1467

Xiong X, Wang YL, Chen ZK, Li GD (2009) Solid State Sci 11:1386

Pasquier S, Lamon J, Naslain R (1998) Compos Part A 29A:1157

Bertrand S, Droillard C, Pailler R, Bourrat X, Naslain R (2000) J Eur Ceram Soc 20:1

Kaur M, Kumar S, Sengupta PR (2009) J Mater Sci 44:2128. doi:10.1007/s10853-009-3307-0

Xu YD, Cheng LF, Zhang LT, Yin HF, Yin XW (2001) Mater Sci Eng A 300:196

Krishnan RR, Gopchandran KG, MahadevanPillai VP, Ganesan V, Sathe V (2009) Appl Surf Sci 255:7126

Acknowledgements

This research work is supported by National Natural Science Foundation of China under the Grant No. 50872154 and by Creative research group of National Natural Science Foundation of China under the Grant No. 50721003.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, Zk., Xiong, X., Li, Gd. et al. Mechanical properties and oxidation behaviors of carbon/carbon composites with C–TaC–C multi-interlayer. J Mater Sci 45, 3477–3482 (2010). https://doi.org/10.1007/s10853-010-4376-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4376-9