Abstract

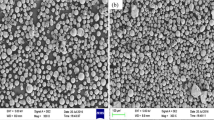

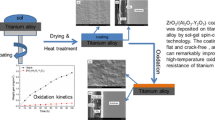

Sol–gel dip coating of SiO2 was applied on a TiAl-based alloy, and subsequent heat treatment was performed. XRD and SEM/EDS analysis revealed that an amorphous silica coating was formed on the alloy. Isothermal oxidation and cyclic oxidation at 600 and 700 °C in static air of the specimens with or without coating were performed to investigate the effect of the SiO2 coating on the oxidation behavior of the alloy by thermogravimetry. The average parabolic rate constants of the coated specimens were greatly reduced due to the presence of the coating. Severe cracks and spallation of the scales were observed on the blank specimens, but not on the coated ones. The oxide scales formed on the uncoated specimens were stratified. For the coated samples, a mixture layer of rutile TiO2 and Al2O3 occurred beneath the applied film.

Similar content being viewed by others

References

Sadeghian Z, Enayati MH, Beiss P (2009) J Mater Sci 44:2566. doi:10.1007/s10853-009-3335-9

Cao R, Zhu H, Chen JH, Zhang J (2008) J Mater Sci 43:299. doi:10.1007/s10853-007-2172-y

Li YL, Feng JC, Peng H, Hua Z (2009) J Mater Sci 44:3077. doi:10.1007/s10853-009-3409-8

Cai JZ, Kulovits A, Shankar MR, Wiezorek J (2008) J Mater Sci 43:7474. doi:10.1007/s10853-008-2887-4

Liu YM, Xiu ZY, Wu GH, Yang WS, Chen GQ, Gou HS (2009) J Mater Sci 44:4258. doi:10.1007/s10853-009-3618-1

Rahmel A, Spencer PJ (1999) Oxid Met 35:53

Tetsui T (2002) Mater Sci Eng A 329–331:582

Yoshihara M, Kim YW (2005) Intermetallics 13:952

Teng LD, Nakatomi D, Seetharaman S (2007) Metall Mater Trans B38:477

Jiang HR, Hirohasi M, Lu Y, Imanari H (2002) Scripta Mater 46:639

Shida Y, Anada H (1996) Oxid Met 45:197

Becker S, Rahmel A, Schorr M, Schutze M (1992) Oxid Met 38:425

Xiong YM, Zhu SL, Wang FH (2005) Surf Coat Technol 190:195

Chu MS, Wu SK (2003) Acta Mater 51:3109

Liang W, Zhao XG (2001) Scripta Mater 44:1049

Xiong HP, Xie YH, Mao W, Ma WL, Chen YF, Li XH, Cheng YY (2003) Scripta Mater 49:1117

Li XY, Taniguchi S, Matsunaga Y (2003) Intermetallics 11:143

Du HL, Datta PK, Lewis DB, Burnell-Gray JS (1995) J Mater Sci 30:2640. doi:10.1007/BF00362147

Mckee DW, Luthra KL (1993) Surf Coat Technol 56:109

Clark RK, Unnan J, Wiedemann KE (1987) Oxid Met 28:391

Fujishiro S, Eylon D (1980) Metall Trans A: Phys Metall Mater Sci 11A:1259

Taniguchi S, Shibada T, Yamada T, Lou H, Wang F, Wu W (1993) Oxid Met 39:457

Chu MS, Wu SK (2004) Surf Coat Technol 179:257

Li H, Liang K, Mei L, Gu S, Wang S (2001) Mater Lett 51:320

Zhang S, Lee WE (2003) J Eur Ceram Soc 23:1215

Zhang XJ, Li Q, Zhao SY, Gao CX, Wang L, Zhang J (2008) App Sur Sci 255:1860

Zhu M, Li MS, Li YL, Zhou YC (2006) Mater Sci Eng A 415:177

Zhang XJ, Li Q, Zhao SY, Gao CX, Zhang ZG (2008) J Sol–Gel Sci Tech 47:107

Zhang XJ, Zhao SY, Gao CX, Wang SJ (2009) J Sol–Gel Sci Tech 49:221

Liu Y, Ren W, Zhang LY, Yao X (1999) Thin Solid Films 353:124

Sarrazin P, Coddet C (1974) Corros Sci 14:83

Barin I (1989) Thermochemical data of pure substrates. VCH, Weinheim

Kobayashi E, Yoshihara M, Tanaka R (1990) High Temp Technol 8:179

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, X.J., Gao, Y.H., Ren, B.Y. et al. Improvement of high-temperature oxidation resistance of titanium-based alloy by sol–gel method. J Mater Sci 45, 1622–1628 (2010). https://doi.org/10.1007/s10853-009-4138-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-4138-8