Abstract

Polysilicon granular beads grown via a fluidized bed reactor, a feedstock for silicon solar cell production, were annealed, sectioned, and indented using a combination of nanoindentation and microhardness testing to determine the mechanical response of this commercially available raw material. The granular material, with macroscopic dimensions on the order of millimeters and an internal grain size on the order of 20 nm, has an indentation modulus of approximately 160 GPa, and a hardness prior to fracture of 9.6 GPa; these values are relatively insensitive to annealing at temperatures between 600 and 1100 °C. Indentation fracture testing suggests the toughness of this material is on the order of 0.6 MPa m1/2. The fracture sequence has been verified using acoustic emission testing during indentation. Annealing in air at 600 °C for 3 days increases the toughness by approximately 50% with little change in grain size. The as grown material contains solute hydrogen, identified by infrared spectroscopy, from the growth process; annealing in air tends to remove solute hydrogen from the material at temperatures above 1050 °C. The removal of solute hydrogen appears to cause slight increases in toughness, while grain growth at elevated annealing temperatures or the formation of hydrogen complexes in the silicon appears to decrease toughness. The results suggest thermal treatments of silicon grown with this method can moderately alter the friability of the final product.

Similar content being viewed by others

References

Caussat B, Hemati M, Couderc JP (1995) Chem Eng Sci 50:3615

Dahl MM, Bellou A, Bahr DF, Norton MG, Osborne EW (2009) J Cryst Growth 311:1496

Ballarini R, Mullen RL, Yin Y, Kahn H, Stemmer S, Heuer AH (1997) J Mater Res 12:915

Cook RF (2006) J Mater Sci 41:841. doi:10.1007/s10853-006-6567-y

Chiao YH, Clarke DR (1989) Acta Met 37:203

John CFSt (1975) Philos Mag 32:1193

Brede M, Hansen P (1988) Acta Met 36:2003

Hirsch PB, Samuels J, Roberts SG (1989) Proc R Soc Lond A 421:25

Chen CP, Leipold MH (1980) Am Ceram Soc Bull 59:469

George A, Michot G (1993) Mater Sci Eng A 164:118

Ericson F, Johansson S, Schweitz JA (1988) Mat Sci Eng A 105:131

Ebrahimi F, Kalwani L (1999) Mat Sci Eng A 268:116

Fancher RW, Watkins CM, Norton MG, Bahr DF, Osborne EW (2001) J Mater Sci 36:5441. doi:10.1023/A:1012425529753

Brodie RC, Bahr DF (2003) Mat Sci Eng A 351:166

Sharpe WN, Yuan B, Edwards RL (1997) Mat Res Soc Symp Proc 505:51

Tsuchiya T, Sakata J, Taga Y (1997) Mat Res Soc Symp Proc 505:285

Kahn H, Tayebi N, Ballarini R, Mullen RL, Heuer AH (2000) Sens Actuators A 82:274

Oliver WC, Pharr GM (1992) J Mater Res 7:1564

Morris DJ, Cook RF (2005) Int J Fract 136:237

Morris DJ, Vodnick AM, Cook RF (2005) Int J Fract 136:265

Cook RF, Pharr GM (1990) J Am Ceram Soc 73:787

von Keudell A, Abelson JR (1998) J Appl Phys 84:489

Acknowledgements

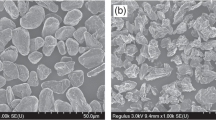

We would like to thank M.M. Dahl for help in sample preparation, microscopy for Fig. 1, and technique development in the handling of silicon granules grown by the FBR.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zbib, M.B., Tarun, M.C., Norton, M.G. et al. Mechanical properties of polycrystalline silicon solar cell feed stock grown via fluidized bed reactors. J Mater Sci 45, 1560–1566 (2010). https://doi.org/10.1007/s10853-009-4124-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-4124-1