Abstract

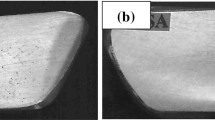

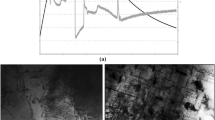

Two cast noncombustible Mg–9Al–1Zn–1Ca alloys (composition in mass%) with coarse and fine initial microstructures were hot forged by compression at temperatures of 523–603 K and a true strain rate of 1–10−2 s−1. The compressive stress–strain curves for the two alloys were similar and typical of metals undergoing dynamic recrystallization (DRX). The alloy with the coarse initial microstructure suffered from edge crack formation during hot forging, while the alloy with the fine initial microstructure exhibited smooth peripheral surfaces after hot forging at temperatures of 573 K and above. The reduction of grain size by DRX was similar in the two hot-forged alloys, but the recrystallized volume fraction was lower in the alloy with the coarse initial microstructure. Insoluble second phases (seemingly Al2Ca) provide additional DRX sites, and thus it is expected that the finer initial cast microstructure will improve the microstructure in the resulting hot-forged Mg parts.

Similar content being viewed by others

References

Ebert T, Mordike BL (2001) Mater Sci Eng A 302:37

Chino Y, Mabuchi M, Shimojima K, Yamada Y, Wen C, Miwa K, Nakamura M, Asahina T, Higashi K, Aizawa T (2001) Mater Trans 42:414

Takigawa Y, Honda M, Uesugi T, Higashi K (2008) Mater Trans 49:1979

Yang X, Miura H, Sakai T (2003) Mater Trans 44:197

Ding H, Liu L, Kamado S, Ding W, Kojima Y (2007) Mater Sci Eng A 452–453:503

Helis L, Okayasu K, Fukutomi H (2006) Mater Sci Eng A 430:98

StJohn DH, Qian M, Easton MA, Cao P, Hildebrand Z (2005) Metall Mater Trans A 36:1669

Li M, Tamura T, Miwa K (2009) J Mater Res 24:145

Akiyama S, Ueno H, Sakamoto M, Hirai H, Kitahara A (2000) Materia Japan 39:72–74 (in Japanese)

Watanabe H, Yamaguchi M, Takigawa Y, Higashi K (2008) Mater Trans 49:1262

Watanabe H, Yamaguchi M, Takigawa Y, Higashi K (2007) Mater Sci Eng A 454–455:384

Chino Y, Jae-Seol L, Nakaura Y, Ohori K, Mabuchi M (2005) Mater Trans 46:2592

Chino Y, Nakaura Y, Ohori K, Kamiya A, Mabuchi M (2007) Mater Sci Eng A 452–453:31

Hakamada M, Watazu A, Saito N, Iwasaki H (2008) Mater Trans 49:554

Humphreys FJ (1991) Mater Sci Eng A 135:267

Hakamada M, Watazu A, Saito N, Iwasaki H (2008) Mater Trans 49:1032

Hakamada M, Watazu A, Saito N, Iwasaki H (2009) Mater Trans 50:711

Thompson AW (1972) Metallography 5:366

Barnett MR (2003) Mater Trans 44:571

Watanabe H, Tsutsui H, Mukai T, Ishikawa K, Okanda Y, Kohzu M, Higashi K (2001) Mater Trans 42:1200

Dehghan-Manshadi A, Hodgson PD (2008) Metall Mater Trans A 39:2830

Tsuzaki K, Huang X, Maki T (1996) Acta Mater 44:4491

Frost HJ, Ashby MF (1982) Deformation-mechanism maps. Pergamon Press, Oxford

Hakamada M, Watazu A, Saito N, Iwasaki H (2008) J Mater Sci 43:2066. doi:https://doi.org/10.1007/s10853-008-2474-8

Acknowledgement

This study was conducted with the financial support of the Forged Magnesium Parts Technological Development Project, which is organized by New Energy and Industrial Technology Development Organization (NEDO), Japan.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hakamada, M., Shimizu, K., Yamashita, T. et al. Effect of initial microstructures on hot forging of Ca-containing cast Mg alloys. J Mater Sci 45, 719–724 (2010). https://doi.org/10.1007/s10853-009-3990-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-3990-x