Abstract

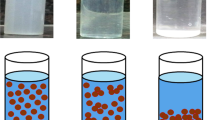

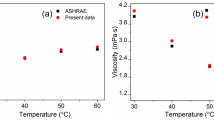

The electrokinetic properties of Nd:YAG nanopowder with particles of about 40 nm in diameter were investigated by measuring the zeta potential of a stable YAG (Y3Al5O12) aqueous slurry. Ammonium poly(acrylic acid) polyelectrolyte was used as dispersant to adjust the electrokinetic properties of the Nd:YAG slurry. The effect of the pH of the slurry and of the polyelectrolyte concentration on the stability of the suspension are discussed in this study. The optimal pH value and the amount of dispersant needed to obtain a stable Nd:YAG nanoparticle slurry were determined. Highly consistent Nd:YAG nanoparticle slurries with optimal pH and dispersant concentration were prepared by ball milling. The rheological behavior of Nd:YAG slip with different solid loading (60–70 wt%) has been studied by measuring the viscosity and shear stress as a function of shear rate. Slip with solid loadings of 65 wt% shows near-Newtonian behavior but becomes non-Newtonian with typical shear-thinning behavior above this solid loading value. The density and microstructure of the cast product bears a direct relationship to the state of the slip induced by alternation of the pH and the concentration of the dispersant as well as the solid loading.

Similar content being viewed by others

References

Cockayne B (1985) J Less Common Met 144:119

Xu WL, Yue TM, Man HC (2008) J Mater Sci 43:942. doi:https://doi.org/10.1007/s10853-007-2208-3

Ahmed MA, Khalil AAI, Solyman S (2007) J Mater Sci 42:4098. doi:https://doi.org/10.1007/s10853-006-1151-z

Corman GS (1991) Ceram Eng Sci Proc 12(9–10):1745

Li J, Wu YS, Pan YB, Kou HM, Shi Y, Guo JK (2008) Ceram Int 34:1675

Feng T, Shi JL, Jiang DY (2008) J Eur Ceram Soc 28(13):2539

Pradhan AK, Zhang K, Loutts GB (2004) Mater Res Bull 39:1291

Zhang HS, Han H, Su CH, Zhang HB, Hou ZX, Song Q (2007) Mater Sci Eng A 445–446:180

Li J, Wu YS, Pan YB, Guo JK (2006) J Non-Cryst Solids 352:2404

Vaidhyanathan B, Binner JGP (2006) J Mater Sci 41:5954. doi:https://doi.org/10.1007/s10853-006-0260-z

Ikesue A, Kinooshita T, Kamata K (1995) J Am Ceram Soc 78:1033

Even-Zur OT, Chaim R (2009) J Mater Sci 44:2063. doi:https://doi.org/10.1007/s10853-009-3300-7

Li X, Li Q (2008) Ceram Int 34:397

Kopylov YL, Kravchenko VB, Bagayev SN, Shemet VV, Komarov AA, Karban OV, Kaminskii AA (2009) Opt Mater 31(5):707

Esposito L, Piancastelli A (2009) J Eur Ceram Soc 29(2):317

Appiagyei KA, Messing GL, Dumm JQ (2008) Ceram Int 34(5):1309

Lu J, Ueda K, Yagi H, Yanagitani T, Akiyama Y, Kaminskii AA (2002) J Alloy Compd 341:220

Yagi H, Yanagitani T, Ueda K (2006) J Alloy Compd 421:195

Kochawattana S, Stevenson A, Lee SH, Ramirez M, Gopalan V, Dumm J, Castillo VK, Quarles GJ, Messing GL (2008) J Eur Ceram Soc 28(7):1527

Naito M, Fukuda Y, Yoshikawa N, Kamiya H, Tsubaki J (1997) J Eur Ceram Soc 17:251

Hirata Y (1997) Ceram Int 23:93

Li Y, Lin J, Gao JQ, Qiao GJ, Wang HJ (2008) Mater Sci Eng A 483–484:676

Kopylov YL, Kravchenko VB, Komarov AA, Lebedeva ZM, Shemet VV (2007) Opt Mater 29:1236

Hotta YJ, Omura NK, Sato K, Watari KJ (2007) J Eur Ceram Soc 27:753

Garrido LB, Agletti EF (2001) J Eur Ceram Soc 21:2259

Moreno R, Salomoni A, Stamenkovic I (1997) J Eur Ceram Soc 17:327

Tsetsekou A, Agrafiotis C, Milias A (2001) J Eur Ceram Soc 21:363

Rao RR, Roopa HN, Kannan TS (1999) Ceram Int 25:223

Houivet D, Fallah JE, Haussonne JM (2002) J Am Ceram Soc 85:321

Lu K, Kessler CS, Davis RM (2006) J Am Ceram Soc 89:2459

Li X, Liu H, Wang JY, Cui HM, Han F (2004) Opt Mater 25:407

Parfitt LR (1981) Dispersion of powders in liquids with special reference to pigments. Applied Science Publishers, London, UK

Wang JQ, Xu HY, Wang Y, Yue YL (2006) J Rare Earth 24:284

Wang HZ, Gao L, Shen ZJ, Nygren M (2001) J Eur Ceram Soc 21:779

Schindler PW (1981) Surface complexes at oxide–water interface. Ann Arbor Science Publishers, Ann Arbor, MI

Parks GA (1965) Chem Rev 65:177

Yoon RH (1979) J Colloid Sci 70:483

Parks GA, DeBruyn PL (1962) J Phys Chem 66:973

Everett DH (1988) Basic principles of colloid science. The Royal Society of Chemistry, Cambridge

Cesarano IIJ, Aksay IA, Bleier A (1988) J Am Ceram Soc 71:250

Yu X, Somasundaran P (1996) J Colloid Interface Sci 177:283

Bergström L (1994) In: Pugh RJ, Bergström L (eds) Surface and colloid chemistry, advanced processing. Marcel Dekker Inc, NY, USA, p 193

Barnes HA, Hutton JF, Walters K (1989) An introduction to rheology. Rheology Series 3. Elsevier Science Publishers B.V., Amsterdam, The Netherlands

Moreno R (2001) In: Messing GL (ed) The encyclopedia of materials. Science and technology.III. Structural materials. Ceramic processing. Elsevier Science, UK, p 8192

Moreno R (2005) Reología de suspensiones cerámicas, Biblioteca de Ciencias, vol 17. CSIC, Madrid, Spain

Sacks MD (1984) Am Ceram Soc Bull 63:1510

Acknowledgements

This research was supported by an NSFC (50872070, 50702031, Innovation Research Group, 50721002), the 973 Program of China (G2004CB619002, 2007CB613302), and the Program of Introducing Talents of Discipline to Universities in China (111 program). Thanks to R. I. Boughton at the Bowling Green State University for English revision on this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lv, YH., Liu, H., Sang, YH. et al. Electrokinetic properties of Nd:YAG nanopowder and a high concentration slurry with ammonium poly(acrylic acid) as dispersant. J Mater Sci 45, 706–712 (2010). https://doi.org/10.1007/s10853-009-3988-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-3988-4