Abstract

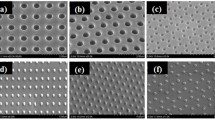

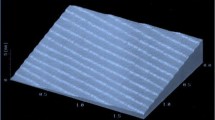

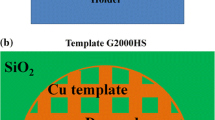

In this study, focused ion beam lithography is used to pattern different size and shape island arrays on silicon wafers. Cavity arrays of inverse shapes are then made on silicone mold surfaces by polymerization. After that, Al2O3 nanoparticle-based island arrays are created by a surface feature transfer and freeze casting process using an Al2O3 colloidal suspension. The effects of silicone mold surface wettability and freezing rate on the Al2O3 nanoparticle pattern quality are investigated. The results show that coating the silicone mold surface with a 10 nm thick Au–Pt layer makes the Al2O3 nanoparticle suspension more wetting on the mold surface and also likely reduces the dry Al2O3 nanoparticle adhesion to the mold surface. Freezing rate should be lower than 1 °C/min to avoid cracks or loose Al2O3 nanoparticle packing in the freeze cast features. When these factors are properly controlled, the reported patterning process allows reproduction of micron-size feature arrays from Al2O3 nanoparticle suspensions. The studied approach should be applicable to most nanoparticle-based materials and open numerous opportunities for direct-device fabrication.

Similar content being viewed by others

References

Shapley JDL, Barrow DA (2001) Thin Solid Films 388:134

Huang J, Moriyoshi T, Manabe H (2006) J Mater Sci 41:1605. doi:https://doi.org/10.1007/s10853-006-4655-7

Huwiler C, Halter M, Rezwan K, Falconnet D, Textor M, Vörös J (2005) Nanotechnology 16:3045

Asoh H, Sakamoto S, Ono S (2007) J Colloid Interface Sci 316:547

Park I, Ko SH, Pan H, Grigoropoulos CP, Pisano AP, Fréchet JMJ, Lee ES, Jeong JJ (2008) Adv Mater 20:489

Liu K, Ho CL, Aouba S, Zhao YQ, Lu ZH, Petrov S, Coombs N, Dube P, Ruda HE, Wong WY, Manners I (2008) Angew Chem Int Ed 47:1255

Xia D, Li D, Luo Y, Brueck SRJ (2006) Adv Mater 18:930

Jung B, Frey W (2008) Nanotechnology 19:145303

Ofir Y, Samanta B, Xiao QJ, Jordan BJ, Xu H, Arumugam P, Arvizo R, Tuominen MT, Rotello VM (2008) Adv Mater 20:2561

Park JI, Lee WR, Bae SS, Kim YJ, Yoo KH, Cheon JW, Kim S (2005) J Phys Chem B 109:13119

Brom CRVD, Arfaoui I, Cren T, Hessen B, Palstra TTM, Hosson JTMD, Rudolf P (2007) Adv Funct Mater 17:2045

Kang M, Kim H, Han BW, Suh JS, Park JH, Choi MS (2004) Microelectronic Eng 71:229

Maury P, Escalante M, Reinhoudt DN, Huskens J (2005) Adv Mater 17:2718

Ma B, Ma J, Goh GKL (2008) J Mater Sci 43:4297. doi:https://doi.org/10.1007/s10853-008-2627-9

Yoldi M, Gonzalez-Vinas W, Arcos MC, Sirera R (2006) J Mater Sci 41:2965. doi:https://doi.org/10.1007/s10853-006-6717-2

Crocker M, Graham UM, Gonzalez R, Jacobs G, Morris E, Rubel AM, Andrews R (2007) J Mater Sci 42:3454. doi:https://doi.org/10.1007/s10853-006-0829-6

Sreethawong T, Chavadej S, Ngamsinlapasathian S, Yoshikawa S (2008) Microporous Mesoporous Mater 109:84

Han L, Shi XJ, Wu W, Kirk FL, Luo J, Wang LY, Mott D, Cousineau L, Lim SI, Lu S, Zhong CJ (2005) Sens Actuators B 106:431

Puetz J, Aegerter MA (2008) Thin Solid Films 516:4495

Lin HY, Tsai LC, Chen CD (2007) Adv Funct Mater 17:3182

Cui TH, Hua F, Lvov Y (2004) Sens Actuators A 114:501

Lu K, Hammond C, Int J Appl Ceram Technol (submitted)

Lu K, Zhu X (2008) Int J Appl Ceram Technol 5(3):219

Lu K (2008) J Mater Sci 43(2):652. doi:https://doi.org/10.1007/s10853-007-2155-z

Lu K (2007) J Am Ceram Soc 90(12):3753

Lu K, Kessler CS, Davis RM (2006) J Am Ceram Soc 89:2459

Lu K, Kessler CS (2006) In: Mullins WN, Wereszczak A, Lara-Curzio E (eds) Ceram engineering and science proceedings, vol 27(8), pp 1–10

Cesarano J, Aksay IA (1988) J Am Ceram Soc 71:1062

Lu K (2009) J Nanosci Nanotechnol 9:2598

Acknowledgement

The authors acknowledge the financial support from National Science Foundation under Grant No. CMMI-0824741.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lu, K., Hammond, C. & Qian, J. Surface patterning nanoparticle-based arrays. J Mater Sci 45, 582–588 (2010). https://doi.org/10.1007/s10853-009-3930-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-3930-9