Abstract

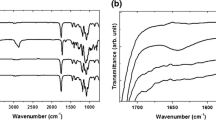

Acrylonitrile–methyl acrylate (AN–MA molar ratio 85/15) copolymer and copolymers containing 5–25 wt% of microencapsulated phase change materials (MicroPCMs) were synthesized by aqueous redox initiated polymerization. MicroPCMs were incorporated into the copolymer at the step of polymerization. The copolymers were processed by environment friendly, solvent-free melt-spinning. The structures and properties of the copolymers and as-spun fibers containing MicroPCMs were characterized by Nuclear Magnetic Resonance (1H NMR), Gel Permeation Chromatography (GPC), Fourier Transform Infrared Spectroscopy (FTIR), Differential Scanning Calorimetry (DSC), Thermogravimetric Analysis (TG), Scanning Electronic Microscope (SEM), X-ray Diffraction (XRD), and Melting Index (MI). The results show that the composition of AN–MA copolymer agrees well with the feeding ratio of AN and MA. The copolymers containing MicroPCMs can be processed at 200 °C. The crystalline enthalpies of the fibers containing 20 and 25 wt% of MicroPCMs are 21 and 25 J/g, respectively; and they increase steadily as the contents of MicroPCMs increase. Tensile strengths of the as-spun fibers are in the range of 1.0–3.2 cN/dtex. The fibers are potentially used as raw materials to fabricate thermo-regulated fabric for comfort clothing.

Similar content being viewed by others

References

Chaurasia PBL (1981) Res Ind 26:159

Colvin DP, Mulligan JC (1990) US Patent 4,911,232

Lennox-kerr P (1998) Techn Text Int 7:25

You M, Zhang XX, Li W et al (2008) Thermochim Acta 472:20

Zhang XX, Li Y, Tao XM, Yick KL (2005) Indian J Fiber Textile Res 30:377

Bryant YG, Colvin DP (1988) US Patent 4756985

Bryant YG (1999) In: American Society of Mechanical Engineers, Bioengineering Division BED Advances in Heat and Mass Transfer in Biotechnology, Nashville, TN, USA, 14–19 November

Zhang XX, Wang XC, Tao XM et al (2005) J Mater Sci 40:3729. doi:10.1007/s10853-005-3314-8

Zhang XX, Fan YF, Tao XM et al (2004) Mater Chem Phys 88(2–3):300

Zhang XX, Tao XM, Yick KL et al (2006) Text Res J 76:351

Clarke AJ, Bailey JE (1973) Nature 243:146

Mukundan T, Bhanu VA, Wiles KB et al (2006) Polymer 47:4163

Bhanu VA, Rangarajan P, Wiles K et al (2002) Polymer 43:4841

Hutchinson SR, Tonelli AE, Gupta BS et al (2008) J Mater Sci 43:5143. doi:10.1007/s10853-008-2727-6

Han N, Zhang XX, Wang XC (2007) Polym Mater Sci Eng 23:45

Rangarajan P, Yang J, Bhanu V et al (2002) J Appl Polym Sci 85:69

Fan YF, Zhang XX, Wu SZ et al (2005) Thermochim Acta 429:25

Zhang XX, Tao XM, Yick KL, Wang XC (2004) Colloid Polym Sci 282:330

Li J, Han N, Zhang XX (2006) J Donghua Univ (Eng Ed) 23:10

Acknowledgements

The authors are thankful to the National Natural Science Found of China (No. 50573058) and Specialized Research Found for the Doctoral Program of Higher Education (No. 20050058004) for the financial supports.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, Xy., Han, N., Zhang, Xx. et al. Melt-processable acrylonitrile–methyl acrylate copolymers and melt-spun fibers containing MicroPCMs. J Mater Sci 44, 5877–5884 (2009). https://doi.org/10.1007/s10853-009-3830-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-3830-z