Abstract

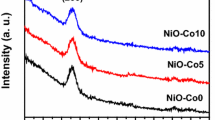

The electrochromic (EC) NiOxHy films were fabricated through a facile sol–gel method. The formation of high quality NiOxHy films came from adding the xerogel back into the sol and prolonging the annealing time at gradually increasing temperature up to 250 °C. Scanning electron microscopy and atomic force microscopy characterizations indicated films were compact, homogenous, and smooth. Glance angle X-ray diffraction investigation testified NiOxHy films were of poor crystallization. The Fourier transform infrared, and thermogravimetry and differential thermal analysis showed that films contained the mixture of NiO, Ni(OH)2, NiOOH, water, and organic substance. With the increasing of the xerogel ratio, the optical absorbance and reflectance of films had larger differences between the colored and bleached state, respectively. The film with the xerogel ratio of 1:5 showed excellent EC properties with a transmittance contrast as high as 60.88% at λ = 560 nm, which was higher than other sol–gel nickel oxide films reported.

Similar content being viewed by others

References

Granqvist CG (1995) Handbook of inorganic electrochromic materials. Elsevier, Amsterdam

Garcia-Miquel JL, Zhang Q, Allen SJ, Rougier A, Blyr A, Davies HO, Jones AC, Leedham TJ, Williams PA, Impey SA (2003) Thin Solid Films 424:165

Ozkan Zayima E, Turhan I, Tepehan FZ, Ozer N (2008) Sol Energy Mater Sol Cells 92:164

Granqvist CG (2006) Nature 5:89

Liu H-R, Zheng W-M, Yan X, Feng B-X (2008) J Alloys Compd 462:356

MiIIer EL, Rocheleau RE (1997) J Electrochem Soc 144:1995

Bouessay I, Rougier A, Tarascon J-M (2004) J Electrochem Soc 151:H145

Wu M-S, Yang C-H (2007) Appl Phys Lett 91:033109

Xia XH, Tua JP, Zhang J, Wang XL, Zhang WK, Huang H (2008) Electrochim Acta 53:5721

Sharma PK, Fantini MCA, Gorenstein A (1998) Solid State Ionics 113–115:457

Moser FH, Lyman NR (1990) US Patent No. 4959247, 25 September

Liu F, Zhou M, Zhong Y-Y, Song Y, Li J-R, Yang W-F, Feng B-X (2008) J Funct Mater 39:1835

Xia XH, Tu JP, Zhang J, Wang XL, Zhang WK, Huang H (2008) Sol Energy Mater Sol Cells 92:628

Lin S-H, Chen F-R, Kai J-J (2008) Appl Surf Sci 254:2017

Ryu HW, Choi GP, Lee WS, Park JS (2004) J Mater Sci 39:4375. doi:https://doi.org/10.1023/B:JMSC.0000033431.52659.e5

Liu X-M, Zhang X-G, Fu S-Y (2006) Mater Res Bull 41:620

Cerc Korošec R, Šauta Ogorevc J, Draškovič P, Dražić G, Bukovec P (2008) Thin Solid Films 516:8264

Šurca A, Orel B, Pihlar B, Bukovec P (1996) J Electroanal Chem 40:83

Cordoba-Torresi SI, Hugot-Le Goff A, Joiret S (1991) J Electrochem Soc 138:1554

Cerc Korošec R, Bukovec P (2004) Thermochim Acta 410:65

Cheng J, Cao G-P, Yang Y-S (2006) J Power Sources 159:734

Cerc Korošec R, Bukovec P, Pihlar B, Padežnik Gomilšek J (2003) Thermochim Acta 402:57

Cerc Korošec R, Bukovec P (2006) Acta Chim Slov 53:136

Wendlandt WW (1964) Thermal methods of analysis. Interscience Publishers, New York, p 17

Acknowledgement

We appreciate the financial supports of the National science Foundation of China (Grant No. 60576013, 60536010 and J0630313).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, F., Zhang, X., Zhu, KW. et al. Facile fabrication of NiOxHy films and their unique electrochromic properties. J Mater Sci 44, 6028–6034 (2009). https://doi.org/10.1007/s10853-009-3816-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-3816-x