Abstract

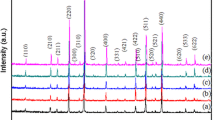

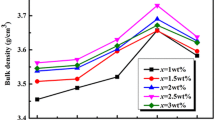

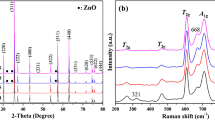

The low-fired (ZnMg)TiO3–TiO2 (ZMT–TiO2) microwave ceramics using low melting point CaO–B2O3–SiO2 as sintering aids have been developed. The influences of Mg substituted fraction on the crystal structure and microwave properties of (Zn1−x Mg x )TiO3 were investigated. The result reveals that the sufficient amount of Mg (x ≥ 0.3) could inhibit the decomposition of ZnTiO3 effectively, and form the single-phase (ZnMg)TiO3 at higher sintering temperatures. Due to the compensating effect of rutile TiO2 (τf = 450 ppm/°C), the temperature coefficient of resonant frequency (τf) for (Zn0.65Mg0.35)TiO3–0.15TiO2 with biphasic structure was adjusted to near zero value. Further, CaO–B2O3–SiO2 addition could reduce the sintering temperature from 1150 to 950 °C, and significantly improve the sinterability and microwave properties of ZMT–TiO2 ceramics, which is attributed to the formation of liquid phases during the sintering process observed by SEM. The (Zn0.65Mg0.35)TiO3–0.15TiO2 dielectrics with 1 wt% CaO–B2O3–SiO2 sintered at 950 °C exhibited the optimal microwave properties: ε ≈ 25, Q × f ≈ 47,000 GHz, and τf ≈ ± 10 ppm/°C.

Similar content being viewed by others

References

Sebastian MT (2008) Dielectric materials for wireless communication. Elsevier

Sebastian MT, Jantunen H (2008) Int Mater Rev 53(2):57

Golovchanshi A, Kim HT, Kim YH (1998) J Korean Phys Soc 32(2):S1167

Kim HT, Kim SH, Nahm S, Byun JD (1999) J Am Ceram Soc 82(11):3043

Yamaguchi O, Morimi M, Kawabata H, Shimizu K (1987) J Am Ceram Soc 70(5):C97

Kim HT, Nahm S, Byun JD, Kim Y (1999) J Am Ceram Soc 82(12):3476

Hsieh M-L, Chen L-S, Wang S-M, Sun C-H, Weng M-H, Houng M-P, Fu S-L (2005) Jpn J Appl Phys 44(7A):5045

Wang Y-R, Wang S-F, Lin Y-M (2005) Ceram Int 31:905

Chaouchi A, d’ Astorg S, Marinel S, Aliouat M (2007) Mater Chem Phys 103:106–111

Lee Y-C, Lee W-H (2005) Jpn J Appl Phys 44(4A):1838

Liu X, Gao F, Zhao L, Tian C (2007) J Alloys Compd 436:285

Chaouchi A, Aliouat M, Marinel S, d’ Astorg S, Bourahla H (2007) Ceram Int 33:245

Lee Y-C, Lee W-H, Shiao F-T (2004) Jpn J Appl Phys 43(11A):7596

Zhang QL, Yang H, Zou JL, Wang HP (2005) Mater Lett 59:880

Chai Y-L, Chang Y-S, Hsiao Y-J, Lian Y-C (2008) Mater Res Bull 43:257

Templeton A, Wang X, Penn SJ, Webb SJ, Cohen LF, Alford NM (2000) J Am Ceram Soc 83(1):95

Zhou X, Li B, Zhang S, Ning H (2009) J Mater Sci: Mater Electron 20:262

Wakino K (1989) Ferroelectric 91:69

Shin H, Shin H-K, Jung HS, Cho S-Y, Hong KS (2005) Mater Res Bull 40(11):2021

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, B., Zhang, S., Yuan, Y. et al. Dielectric properties and microstructure of TiO2 modified (ZnMg)TiO3 microwave ceramics with CaO–B2O3–SiO2 . J Mater Sci 44, 4993–4998 (2009). https://doi.org/10.1007/s10853-009-3763-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-3763-6