Abstract

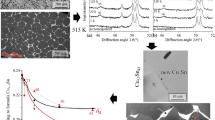

Dissolution kinetics of cobalt in liquid 87.5%Sn–7.5%Bi–3%In–1%Zn–1%Sb and 80%Sn–15%Bi–3%In–1%Zn–1%Sb soldering alloys and phase formation at the cobalt–solder interface have been investigated in the temperature range of 250–450 °C. The temperature dependence of the cobalt solubility in soldering alloys was found to obey a relation of the Arrhenius type cs = 4.06 × 102 exp (−46300/RT) mass% for the former alloy and cs = 5.46 × 102 exp (−49200/RT) mass% for the latter, where R is in J mol−1 K−1 and T in K. For tin, the appropriate equation is cs = 4.08 × 102 exp (−45200/RT) mass%. The dissolution rate constants are rather close for these soldering alloys and vary in the range (1–9) × 10−5 m s−1 at disc rotational speeds of 6.45–82.4 rad s−1. For both alloys, the CoSn3 intermetallic layer is formed at the interface of cobalt and the saturated or undersaturated solder melt at 250 °C and dipping times up to 1800 s, whereas the CoSn2 intermetallic layer occurs at higher temperatures of 300–450 °C. Formation of an additional intermetallic layer (around 1.5 μm thick) of the CoSn compound was only observed at 450 °C and a dipping time of 1800 s. A simple mathematical equation is proposed to evaluate the intermetallic-layer thickness in the case of undersaturated melts. The tensile strength of the cobalt-to-solder joints is 95–107 MPa, with the relative elongation being 2.0–2.6%.

Similar content being viewed by others

References

Frear DR (1999) JOM 51:22

Lee MS, Chen C, Kao CR (1999) Chem Mater 11:292

Tao WH, Chen C, Ho CE, Chen WT, Kao CR (2001) Chem Mater 13:1051

Lalena JN, Dean NF, Weiser MW (2002) J Electron Mater 31:1244

Chiu MY, Wang SS, Chuang TH (2002) J Electron Mater 31:494

Alam MO, Chan YC, Tu KN (2003) J Appl Phys 94:4108

Yoon J-W, Kim S-W, Koo J-M, Kim D-G, Jung S-B (2004) J Electron Mater 33:1190

Lee H-T, Lin H-S, Lee C-S, Chen P-W (2005) Mater Sci Eng A 407:36

Liu PL, Shang JK (2005) Scripta Mater 53:631

Rizvi MJ, Chan YC, Bailey C, Lu H, Islam MN (2006) J Alloys Compd 407:208

Wang C-h, Chen S-w (2006) Acta Mater 54:247

Suganuma K, Lee J-E, Kim K-S (2007) In: Abstracts MRS 2007 Spring meeting, San Francisco, CA, 9–13 April 2007, E1.6

Bieler T, Borgesen P, Xing Y, Lehman L, Cotts E (2007) In: Abstracts of MRS 2007 Spring meeting, San Francisco, CA, 9–13 April 2007, E4.6

Chason E, Reinbold L, Jadhav N, Kelly V, Shin JW, Buchovecky E, Hariharaputran R, Kumar S (2007) In: Abstracts of MRS 2007 Spring meeting, San Francisco, CA, 9–13 April 2007, E2.4

Ursula K, Moon K, Handwerker C (2007) In: Abstracts of materials science and technology 2007 conference and exhibition, Detroit, MI, 16–20 September 2007, p 344

Anderson IE, Walleser J, Rehbein D, Kracher A, Harringa J (2007) In: Abstracts of materials science and technology 2007 conference and exhibition, Detroit, MI, 16–20 September 2007, p 344

Grossklaus KA, Handwerker CA, Stach EA, Revur RR, Sengupta S, Hwang H (2007) In: Abstracts of materials science and technology 2007 conference and exhibition, Detroit, MI, 16–20 September 2007, p 345

Ogunseitan OA (2007) JOM 59(7):12

Subramanian KN (ed) (2007) Lead-free electronic solders. Springer, Berlin, 378 pp

Tu KN (2007) Solder joint technology. Springer, Berlin, p 370

Zhu W, Wang J, Liu H, Jin Z, Gong W (2007) Mater Sci Eng 456:109

Wang H, Wang F, Gao F, Ma X, Qian Y (2007) J Alloys Compd 433:302

Lin C-T, Hsi C-S, Wang M-C, Chang T-C, Liang M-K (2008) J Alloys Compd 459:225

Barmak K, Berry DC, Khoruzha VG, Sidorko VR, Meleshevich KA, Samelyuk AV, Dybkov VI (2008) In: Proceedings of the materials science and technology conference: Pb-free, Pb-bearing joining and packaging materials and processes for microelectronics, Pittsburgh, PA, 5–9 October 2008, p 262

Cheng F, Nishikawa H, Takemoto T (2008) J Mater Sci 43:3643. doi:https://doi.org/10.1007/s10853-008-2580-7

Gao F, Cheng F, Nishikawa H, Takemoto T (2008) Mater Lett 62:2257

Liu CZ, Zhang W (2009) J Mater Sci 44:149. doi:https://doi.org/10.1007/s10953-008-3118-8

Ma H, Suhling JC (2009) J Mater Sci 44:1141. doi:https://doi.org/10.1007/s10853-008-3125-9

Cheng F, Gao F, Nishikawa H, Takemoto T (2009) J Alloys Compd 472:530

Wang F, O’Keefe M, Brinkmeyer B (2009) J Alloys Compd 477:267

Wang YW, Chang CC, Kao CR (2009) J Alloys Compd 478:L1

Wang YW, Lin YW, Tu CT, Kao CR (2009) J Alloys Compd 478:121

Hauffe K (1955) Reaktionen in und an festen Stoffen. Springer, Berlin

Seith W (1955) Diffusion in metallen. Springer, Berlin

Hedvall JA (1966) Solid state chemistry. Elsevier, Amsterdam

Chebotin VN (1982) Fizicheskaya khimiya tverdogo tela. Khimiya, Moskwa

Dybkov VI (2002) Reaction diffusion and solid state chemical kinetics. IPMS, Kyiv

Hansen M (1958) Constitution of binary alloys. McGraw-Hill, New York

Lashko SV, Lashko NF (1988) Paika metallov. Mashinostroenie, Moskwa

Shunk FA (1969) Constitution of binary alloys: second supplement. McGraw-Hill, New York

Massalski TB, Murray JL, Bennett LH, Baker H (eds) (1986) Binary alloy phase diagrams, vol 2. American Society of Metals, Metals Park

Lyakishev NP (ed) (1999) Diagrammy sostoyaniya dvoynikh metallicheskikh sistem, vol 3, Part 1. Mashinostroenie, Moskwa

Jiang M, Sato J, Ohnuma I, Kainuma R, Ishida K (2004) Calphad 28:213

Okamoto H (2006) J Phase Equilib Diffus 27:308

Gurov KP, Kartashkin BA, Ugaste YuE (1981) Vzaimnaya diffusiya v mnogofaznikh metallicheskikh sistemakh. Nauka, Moskwa

Barmak K, Dybkov VI (2003) J Mater Sci 38:3249. doi:https://doi.org/10.1023/A:1025129803413

Dybkov VI, Barmak K, Lengauer W, Gas P (2005) J Alloys Compd 389:61

Levich VG (1959) Fiziko-Khimicheskaya Hidrodinamika. Fizmatgiz, Moskwa

Kassner TF (1967) J Electrochem Soc 114:689

Vol AE (1962) Stroeniye i svoistva dvoynikh metallicheskikh system, vol 2. Fizmatgiz, Moskwa

Lang A, Jeitschko W (1996) Z Metallkd 87:759

Nial O (1938) Z Anorg Allg Chem 238:287

Matveyeva NM, Nikitina SV, Zezin SB (1968) Izv Akad Nauk SSSR Met 5:194

Djega Mariadassou C, Lecocq P, Michel A (1969) Ann Chim 4:175

Panteleimonov LA, Portnova GF, Nesterova OP (1971) Vestnik Moskov Univ Khimiya 26:79

Havinga EE, Damsma H, Hokkeling P (1972) J Less-Common Met 27:169

Buschow KHJ, van Engen PG, Jongebreur R (1983) J Magn Magn Mater 38:1

Cobalt Tin, ICDD, PDF2, 1999, File 00-02-0559, α-CoSn3

Cobalt Tin, Pauling File Binary Edition, Inorganic Materials, 2002. https://doi.org/crystdb.nims.go.jp

Chao Y-H, Chen S-W, Chang C-H, Chen C-C (2008) Metall Mater Trans A 39:477

Zhu W, Liu H, Wang J, Jin Z (2008) J Alloys Compd 456:113

Wang C-h, Chen S-w (2007) J Mater Res 22:3404

Dybkov VI (2009) JOM 61:78

Acknowledgements

This investigation was supported in part by the CRDF Grant No. UKE2-2698-KV-06. The authors thank D.M. Pashko for machining cobalt specimens and other mechanical work, L.A. Duma for taking X-ray patterns, L.M. Kuzmenko for carrying out chemical analyses, E.S. Rabotina for making metallic cross-sections, and I.G. Kondratenko and S.V. Bykova for their help in conducting the experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dybkov, V.I., Khoruzha, V.G., Sidorko, V.R. et al. Interfacial interaction of solid cobalt with liquid Pb-free Sn–Bi–In–Zn–Sb soldering alloys. J Mater Sci 44, 5960–5979 (2009). https://doi.org/10.1007/s10853-009-3717-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-3717-z