Abstract

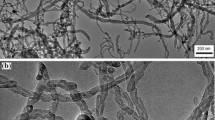

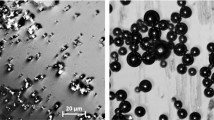

Smart composites based on carbonyl-iron particles in a polyurethane matrix, known as magnetorheological elastomers (MREs), were manufactured and studied. The influence of ferromagnetic particle content and particle arrangement in relation to an external magnetic field was investigated. Several different elastomers with different stiffnesses were used as matrices. It was found that the structure of a fabricated MRE depends on the viscosity of the matrix before curing and the flux density of the applied magnetic field. Two different magnetic field strengths were used: 0.1 and 0.3 T. The amount of carbonyl iron particles was varied from 1.5 to 33.0 vol%. Scanning electron microscopy technique was used to observe MRE microstructure. The particles’ orientation and their arrangement were also investigated by vibrating sample magnetometer. A correlation was found between MRE microstructure and magnetic properties. Compression tests on cylindrical samples in the presence and absence of a magnetic field showed that a magnetic field increased the stiffness of the material. Additionally the rheological properties of MREs were tested in a magnetic field. It was found that the amount of ferromagnetic particles and their arrangement have a significant influence on the rheological properties of MREs. The highest relative change of storage modulus under 200 mT magnetic field, equal to 282%, was recorded for samples with 11.5 vol% of particles.

Similar content being viewed by others

References

Zhou GY (2003) Smart Mater Struct 12:139

Farshad M, Benine A (2004) Polym Test 23:347

Jolly MR, Carlson JD, Munoz BC, Bullions TA (1996) J Intel Mater Syst Struct 7:613

Khoo M, Liu C (2001) Sens Actuat A Phys 89:259

Carlson JD, Jolly MR (2000) Mechatronics 10:555

Varga Z, Filipcsei G, Zrinyi M (2005) Polymer 46:7779

An Y, Shaw MT (2003) Smart Mater Struct 12:157

Lokander M, Stenberg B (2003) Polym Test 22:245

Banks HT, Pinter GA, Potter LK, Gaitens MJ, Yanyo LC (1999) J Intel Mater Syst Struct 10:116

Liu B, Shaw MT (2001) J Intel Mater Syst Struct 12:57

Lokander M, Stenberg B (2003) Polym Test 22:677

Farshad M, Le Roux M (2004) Polym Test 23:855

Kallio M, Aalto S, Lindroos T, Jarvinen E, Karna T, Meinander T (2003) In: Proceedings of AMAS workshop on smart materials and structures, SMART’03, Jadwisin, pp 353–360

Lokander M, Reitberger T, Stenberg B (2004) Polym Degrad Stabil 86:467

Farshad M, Le Roux M (2005) Polym Test 24:163

Boczkowska A, Awietjan S.F, Wejrzanowski T, Kurzydłowski K.J (2009) J Mater Sci, in press

Acknowledgement

This study is financed as a R&D Project from funds of the Polish Ministry of Science and Higher Education (Grant no. NR15 0010 04).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Boczkowska, A., Awietjan, S.F. Smart composites of urethane elastomers with carbonyl iron. J Mater Sci 44, 4104–4111 (2009). https://doi.org/10.1007/s10853-009-3592-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-3592-7