Abstract

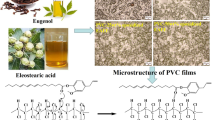

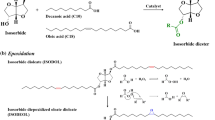

One of the most useful polymeric materials at industrial scale is plasticized polyvinyl chloride (P-PVC) or PVC plastisol. This is characterized by optimum balance among processing conditions, overall properties, cost, and versatility; however, it has some problems related to plasticizer migration (generally phthalates derivatives) with toxicity problems. As a consequence of the appearance of new regulations which restrict the use of phthalates, the study of new plasticizers with low toxicity and low migration has become a very interesting research field. In this study, the optimum curing conditions of vinyl plastisols with a natural-based epoxidized fatty acid ester as plasticizer have been investigated by the following mechanical properties: thermal behavior, color changes, solvent migration, and microstructure changes in terms of the curing conditions. This study was carried out with a plasticizer content of 70 phr (per hundred resin); different isothermal curing conditions ranging from 160 to 220 °C, and curing times in the 6–10 min range were used. The results revealed that the best curing conditions are 200 and 220 °C for curing times near to 14 and 10 min, respectively, which are similar to those used for other commonly used plasticizers.

Similar content being viewed by others

References

Biedermann-Brem S, Biedermann M, Fiselier K, Grob K (2005) Food Addit Contam 22:1274

Jimenez A, Lopez J, Iannoni A, Kenny JM (2001) J Appl Polym Sci 81:1881

Marcilla A, Garcia S, Garcia-Quesada JC (2008) Polym Test 27:221

Shea KM (2003) Pediatrics 111:1467

Wang Q, Storm BK (2005) Polym Test 24:290

Directive (2005) 2005/84/EC of the European Parliament and of the Council of 14 December 2005; Published 27.12.2005 in the Official Journal of the European Union; L 344/40–L 344/43

Public Law (2008) 110–314—August 14, 2008 enacted by the Senate and House of Representatives of the United States of America, 3016–3077

Kawamura Y, Kanno S, Mutsuga M, Tanamoto K (2006) J Food Hyg Soc Jpn 47:243

Pedersen GA, Jensen LK, Fankhauser A, Biedermann S, Petersen JH, Fabech B (2008) Food Addit Contam 25:503

Banu D, El-Aghoury A, Feldman D (2006) J Appl Polym Sci 101:2732

Gil N, Saska M, Negulescu I (2006) J Appl Polym Sci 102:1366

Baltacioglu H, Balkose D (1999) J Appl Polym Sci 74:2488

Benaniba MT, Belhaneche-Bensemra N, Gelbard G (2003) Polym Degrad Stab 82:245

Lee JH, Park CW, Noh I (1995) Polymer (Korea) 19:543

Yousef EAA, Hussain AE, Shoeb ZE (2001) J Sci Ind Res 60:383

Rusling JF, Riser GR, Snook ME, Scott WE (1968) J Am Oil Chem Soc 45:760

Gan LH, Ooi KS, Goh SH, Gan LM, Leong YC (1995) Eur Polym J 31:719

Zhu J, Chandrashekhara K, Flanigan V, Kapila S (2004) J Appl Polym Sci 91:3513

Bouchareb B, Benaniba MT (2008) J Appl Polym Sci 107:3442

Starnes WH, Du B, Kim S, Zaikov VG, Ge XL, Culyba EK (2006) Thermochim Acta 442:78

Wang GQ, Chen YT (1991) Polym Test 10:315

Boussoum MO, Atek D, Belhaneche-Bensemra N (2006) Polym Degrad Stab 91:579

Goto H, Saeki A, Nishikino H, Higaki Y, Iida T (1994) Kobunshi Ronbunshu 51:511

Lopez J, Balart R, Jimenez A (2004) J Appl Polym Sci 91:538

Nakajima N, Yavornitzky CM, Roche EJ, Harrell ER (1986) J Appl Polym Sci 32:3749

Kwak SY (1995) J Appl Polym Sci 55:1683

Garcia D, Balart R, Parres F, Lopez J (2007) J Mater Sci 42:10143. doi:https://doi.org/10.1007/s10853-007-2067-y

Hashimoto K, Suga S, Wakayama Y, Funazukuri T (2008) J Mater Sci 43:2457. doi:https://doi.org/10.1007/s10853-007-2015-x

Crespo JE, Balart R, Sanchez L, Lopez J (2007) J Appl Polym Sci 104:1215

Garcia JC, Marcilla A (1998) Polymer 39:3507

Marcilla A, Garcia JC (1997) Eur Polym J 33:349

Marcilla A, Garcia JC (1997) Eur Polym J 33:357

Jourdan JS, Owen DP (2008) J Vinyl Addit Technol 14:99

JE Crespo JE (2005) PhD Thesis, Alcoy, Polytechnic University of Valencia, p 612

Acknowledgement

Authors thank microscopy services at UPV for their assistance in using SEM technique.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fenollar, O., Sanchez-Nacher, L., Garcia-Sanoguera, D. et al. The effect of the curing time and temperature on final properties of flexible PVC with an epoxidized fatty acid ester as natural-based plasticizer. J Mater Sci 44, 3702–3711 (2009). https://doi.org/10.1007/s10853-009-3495-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-3495-7