Abstract

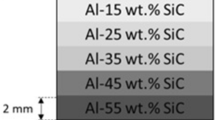

Al2O3/h–BN machinable composites were cost-effectively fabricated by pressureless sintering method. The machinability, deformation, and cracks behavior of the composites were investigated by drilling, Hertzian indentation, and Vickers indentation test, respectively. Through the observation of the microstructures in different scales by SEM, we analyzed the role of the weak boundary phases (WBP), including h-BN and pores, on the machining mechanism of the composites. The results showed that almost all of the WBP dispersed at the Al2O3 grain boundaries, which strongly elevate the machinability and deformability of the composites. During the drilling or Hertzian indentation test, a large number of microcracks formed firstly along the WBP; then these microcracks connected with each other causing a removal or macro-deformation of the composites. The Vickers indentation test result indicated that the weak interfaces and grain boundaries of WBP lead to a low microcrack toughness, whereas in macro-scale the crack toughness was improved because of the crack bridging and deflection of WBP.

Similar content being viewed by others

References

Grossman DG (1972) J Am Ceram Soc 55:446. doi:https://doi.org/10.1111/j.1151-2916.1972.tb11337.x

Kusunose T, Sekino T, Choa YH, Niihara K (2002) J Am Ceram Soc 85:2678. doi:https://doi.org/10.1111/j.1151-2916.2002.tb00514.x

Li YL, Qiao GJ, Jin ZH (2002) Mater Res Bull 37:1401. doi:https://doi.org/10.1016/S0025-5408(02)00786-9

Li YL, Zhang JX, Qiao GJ, Jin ZH (2005) Mater Sci Eng A 397:35. doi:https://doi.org/10.1016/j.msea.2005.01.038

Wang XD, Qiao GJ, Jin ZH (2004) J Am Ceram Soc 87:565. doi:https://doi.org/10.1111/j.1551-2916.2004.00565.x

Baskaran S, Halloran JW (1993) J Am Ceram Soc 76:2217. doi:https://doi.org/10.1111/j.1151-2916.1993.tb07757.x

Padture NP, Evans CJ, Hockin HKX, Lawn BR (1995) J Am Ceram Soc 78:215. doi:https://doi.org/10.1111/j.1151-2916.1995.tb08386.x

Davis JB, Marshall DB, Housley RM, Morgan PED (1998) J Am Ceram Soc 81:2169. doi:https://doi.org/10.1111/j.1151-2916.1998.tb02602.x

Suganuma K, Sasaki G, Fujita T, Okumura M, Niihara K (1993) J Mater Sci 28:1175. doi:https://doi.org/10.1007/BF01191949

Kawai C, Yamakawa A (1997) J Am Ceram Soc 80:2705. doi:https://doi.org/10.1111/j.1151-2916.1997.tb03179.x

Barsoum MW, El-Raghy T (1996) J Am Ceram Soc 79:1953. doi:https://doi.org/10.1111/j.1151-2916.1996.tb08018.x

Shi ZQ, Wang JP, Qiao GJ, Jin ZH (2008) Mater Sci Eng A 492:29. doi:https://doi.org/10.1016/j.msea.2008.03.004

Lawn BR, Padture NP, Cai HD, Guiberteau F (1994) Science 263:1114. doi:https://doi.org/10.1126/science.263.5150.1114

Kusunose T, Sekino T, Choa YH, Niihara K (2002) J Am Ceram Soc 85:2689. doi:https://doi.org/10.1111/j.1151-2916.2002.tb00515.x

Cai HD, Kalceff MAS, Lawn BR (1994) J Mater Res 9:762. doi:https://doi.org/10.1557/JMR.1994.0762

Xu HHK, Jahanmir S (1995) J Am Ceram Soc 78:497. doi:https://doi.org/10.1111/j.1151-2916.1995.tb08831.x

Padture NP (1994) J Am Ceram Soc 77:519. doi:https://doi.org/10.1111/j.1151-2916.1994.tb07024.x

Fischer-Cripps AC, Lawn BR (1996) J Am Ceram Soc 79:2609. doi:https://doi.org/10.1111/j.1151-2916.1996.tb09023.x

Latella BA, O’Connor BH, Padture NP, Lawn BR (1997) J Am Ceram Soc 80:1027. doi:https://doi.org/10.1111/j.1151-2916.1997.tb02940.x

Lawn BR (1998) J Am Ceram Soc 81:1977. doi:https://doi.org/10.1111/j.1151-2916.1998.tb02580.x

Zhang ZF, He G, Eckert J, Schultz L (2003) Phys Rev Lett 91:045505. doi:https://doi.org/10.1103/PhysRevLett.91.045505

Yoon YS, Na SW, Lee J, Cho MW, Lee ES, Cho WS (2004) J Am Ceram Soc 87:1374. doi:https://doi.org/10.1111/j.1151-2916.2004.tb07740.x

Cho WS, Cho MW, Lee JH, Munir ZA (2006) Mater Sci Eng A 418:61. doi:https://doi.org/10.1016/j.msea.2005.11.033

Jiang T, Jin ZH, Yang JF, Qiao GJ (2008) Mater Sci Eng A 494:203. doi:https://doi.org/10.1016/j.msea.2008.04.047

Acknowledgement

This study was funded by National Natural Science Foundation of China (No. 50772086).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shi, Z., Wang, J., Qiao, G. et al. Machinability, deformation, and cracks behavior of pressureless-sintered Al2O3/h-BN composites: role of weak boundary phases. J Mater Sci 44, 1580–1587 (2009). https://doi.org/10.1007/s10853-008-3242-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-3242-5