Abstract

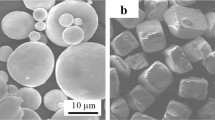

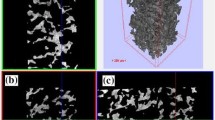

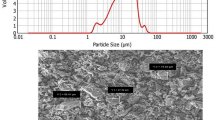

Open cell Ti6Al4V foams (60% porosity) were prepared at sintering temperatures between 1,200 and 1,350 °C using ammonium bicarbonate particles (315–500 μm) as space holder. The resulting cellular structure of the foams showed bimodal pore size distribution, comprising macropores (300–500 μm) and micropores (1–30 μm). Compression tests have shown that increasing sintering temperature increased the elastic modulus, yield and compressive strength, and failure strain of foams. The improvements in the mechanical properties of foams prepared using smaller size Ti64 powder with bimodal particle distribution were attributed to the increased number of sintering necks and contact areas between the particles. Finally, the strength of foams sintered at 1,350 °C was found to satisfy the strength requirement for cancellous bone replacement.

Similar content being viewed by others

References

Long M, Rack HJ (1998) Biomaterials 19:1621

Pilliar RM (1987) J Biomed Mater Res-Appl Biomater 21:1

Hulbert SF, Young FA, Mathews RS, Klawitter JJ, Talbert CD, Stelling FH (1970) J Biomed Mater Res 4:433

Bobyn JD, Miller JE (1994) Features of biologically fixed devices. American Academy of Orthopaedic Surgeons, Chicago

Oh IH, Nomura N, Hanada S (2002) Mater Trans 43:443

Wen CE, Yamada Y, Shimojima K, Chino Y, Asahina T, Mabuchi M (2002) J Mater Sci-Mater Med 13:397

Assad M, Likibi F, Jarzem P, Leroux MA, Coillard C, Rivard CH (2004) Materialwiss Werkstofftech 35:219

ASTM F 1580-95, Standard specification for titanium and Ti6Al4V alloy powders for coating surgical implants.

Martin B, Stiller C, Buchkremer HP, Stöver D, Baur H (2000) Adv Eng Mater 2:196

Rho JY, Kuhn-Spearing L, Zioupos P (1998) Med Eng Phys 20:92

Tasdemirci A, Hızal A, Altındis M, Hall IW, Guden M (2008) Mater Sci Eng A 474:335

Guden M, Celik E, Cetiner S, Aydin A (2004) In: Biomaterials: from molecules to engineered tissues, p 257

Tencer F, Johnson KD (1994) In: Biomechanics in orthopaedic trauma: bone fracture and fixation. Martin Dunitz Ltd, London, p 954

Burstein AH, Reilly DT, Martens M (1976) J Bone Joint Surg 58A:82

Chang YS, Oka M, Kobayashi M, Gu HO, Li ZL, Nakamura T, Ikada Y (1996) Biomaterials 17:1141

Acknowledgement

The authors would like to thank the Technology Development Foundation of Turkey (TTGV) for the grant #TTGV-102/T13.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dizlek, M.E., Guden, M., Turkan, U. et al. Processing and compression testing of Ti6Al4V foams for biomedical applications. J Mater Sci 44, 1512–1519 (2009). https://doi.org/10.1007/s10853-008-3038-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-3038-7