Abstract

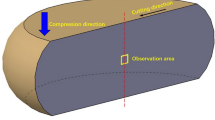

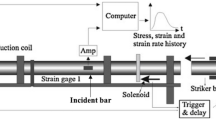

In this paper, the plastic deformation behavior and strain homogeneity of the ZK60 Mg alloy during the multi-pass cyclic extrusion and compression (CEC) was simulated using the finite-element method (FEM) with a view to provide an insight into the mechanics of the process. Physical modeling (PM) experiment with same alloy was carried out to verify the results of the numerical simulations. The results show that two vortex flow regions with opposite flow direction are formed inside the cylindrical workpiece during CEC deformation. Although the deformation is inhomogeneous in both end regions of workpiece, a uniform region of equivalent strain exists, and the extent of uniform deformation increased with the increase in workpiece length.

Similar content being viewed by others

References

Valiev RZ, Islamgaliev RK, Alexandrov IV (2000) Prog Mater Sci 45:103. doi:https://doi.org/10.1016/S0079-6425(99)00007-9

Valiev RZ, Estrin Y, Horita Z, Langdon TG, Zehetbauer MJ, Zhu YT (2006) JOM 58(4):33. doi:https://doi.org/10.1007/s11837-006-0213-7

Lin JB, Wang QD, Peng LM, Peng T (2008) Mater Trans 49:1021. doi:https://doi.org/10.2320/matertrans.MC200766

Valiev RZ (2007) J Mater Sci 42:1483. doi:https://doi.org/10.1007/s10853-006-1281-3

Wang QD, Lin JB, Peng LM, Chen YJ (2008) Acta Metall Sinica 44(1):55

Richert J, Richert M (1986) Aluminium 62(8):604

Lin JB, Wang QD, Peng LM, Roven HJ (2008) J Alloys Compd. doi:https://doi.org/10.1016/j.jallcom.2008.09.031

Richert M, Liu Q, Hansen N (1999) Mater Sci Eng A 260:275. doi:https://doi.org/10.1016/S0921-5093(98)00988-5

Lee SW, Yeh JW (2005) Metall Mater Trans A 36:2225. doi:https://doi.org/10.1007/s11661-005-0341-7

Petrescu D, Savage SC, Hodgson PD (2002) J Mater Process Technol 125–126:361. doi:https://doi.org/10.1016/S0924-0136(02)00301-1

Nagasekhar AV, Kim HS (2008) Comput Mater Sci. doi: 10.1016/jcommatsci2008.02.030

Zhao WJ, Ding H, Ren YP, Hao SM, Wang J, Wang JT (2005) Mater Sci Eng A 410–411:348. doi:https://doi.org/10.1016/j.msea.2005.08.134

Dumoulin S, Roven HJ, Werenskiold JC, Valberg HS (2005) Mater Sci Eng A 410–411:248. doi:https://doi.org/10.1016/j.msea.2005.08.103

Tham YW, Fu MW, Hng HH, Yong MS, Lim KB (2007) J Mater Process Technol 192–193:121. doi:https://doi.org/10.1016/j.jmatprotec.2007.04.030

Gavrus A, Massoni E, Chenot JL (1996) J Mater Process Technol 60:447. doi:https://doi.org/10.1016/0924-0136(96)02369-2

Rosochowski A, Olejnik L (2002) J Mater Process Technol 125–126:309. doi:https://doi.org/10.1016/S0924-0136(02)00339-4

MSC.Superform 2005, Command reference manual

Richert M, Korbel A (1995) J Mater Process Technol 53:331. doi:https://doi.org/10.1016/0924-0136(95)01990-V

Choi I, Horgan CO (1977) J Appl Mech 44:424

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 50674067), National Basic Research Program of China (No. 2007CB613701) and Program of Shanghai Subject Chief Scientist (No. 08XD14020). Special thanks to Snorre Kjørstad Fjeldbo for useful comments on the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, J., Wang, Q., Peng, L. et al. Study on deformation behavior and strain homogeneity during cyclic extrusion and compression. J Mater Sci 43, 6920–6924 (2008). https://doi.org/10.1007/s10853-008-2994-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-2994-2