Abstract

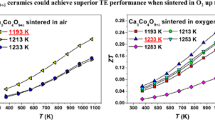

A series of Ca3−xGdxCo4O9+δ precursor powders were synthesized by the polyacrylamide gel method, and their ceramics were obtained by the Spark Plasma Sintering (SPS). There were lots of defects in the sheet-like grains from SEM and TEM observations. The electrical and the thermal transport properties were obviously affected by the material microstructure. The small polaron hopping conduction mechanism was determined above 600 K, and the hopping activation energy increased with the increase of doping contents. It was found that the Seebeck coefficient and the resistivity of doped samples were markly enhanced due to the impurity compensation effect, and their thermal conductivities were decreased due to the defects scattering. The maximum figure of merit of ZT = 0.24 at 973 K was obtained for Ca2.7Gd0.3Co4O9+δ.

Similar content being viewed by others

References

Park K, Kim KK, Seong JK (2007) Mater Lett 61:4759. doi:https://doi.org/10.1016/j.matlet.2007.03.021

Zhang LH, Tosh T, Norlyuki O et al (2007) Mater Trans 48:2088. doi:https://doi.org/10.2320/matertrans.E-MRA2007836

Park K, Ko KY, Seong JK et al (2007) J Eur Ceram Soc 27:3735. doi:https://doi.org/10.1016/j.jeurceramsoc.2007.02.030

Yasukawa M, Itoh S, Kono T (2005) J Alloy Compd 390:250. doi:https://doi.org/10.1016/j.jallcom.2004.07.061

Androulakis J, Hsu KF, Pcionek R (2006) Adv Mater 18:1170. doi:https://doi.org/10.1002/adma.200502770

Terasaki I, Sasago Y, Uchinokura K (1997) Phys Rev B 56:R12685. doi:https://doi.org/10.1103/PhysRevB.56.R12685

Masset AC, Michel C, Maignan A et al (2000) Phys Rev B 62:166. doi:https://doi.org/10.1103/PhysRevB.62.166

Koshibae W, Tsutsui K, Maekawa S (2000) Phys Rev B 62:6869. doi:https://doi.org/10.1103/PhysRevB.62.6869

Shikano M, Funahashi R (2003) Appl Phys Lett 82:1851. doi:https://doi.org/10.1063/1.1562337

Creon N, Perez O, Hadermann J (2006) Chem Mater 18:5355. doi:https://doi.org/10.1021/cm061163a

Prevel M, Perez O, Noudem JG (2007) Solid State Sci 9:231. doi:https://doi.org/10.1016/j.solidstatesciences.2007.01.003

Matsubara I, Funahashi R, Tomonari T (2001) J Appl Phys 90:462. doi:https://doi.org/10.1063/1.1378056

Asahi R, Sugiyama J, Tani T (2002) Phys Rev B 66:155103. doi:https://doi.org/10.1103/PhysRevB.66.155103

Wang DL, Chen LD, Wang Q et al (2004) J Alloy Compd 376:58. doi:https://doi.org/10.1016/j.jallcom.2003.12.018

Kobayashi T, Takizawa H, Endo T (1991) J Solid State Chem 92:116. doi:https://doi.org/10.1016/0022-4596(91)90248-G

Wang Y, Nyrissa S, Cava RJ et al (2003) Nature 423:425. doi:https://doi.org/10.1038/nature01639

Takeuchi T (2004) Phys Rev B 69:125410. doi:https://doi.org/10.1103/PhysRevB.69.125410

Acknowledgements

The authors would like to thank the financial supports from National Basic Research Program of China (973 program) under Grant No. 2007CB607502, the National Natural Science Foundation of China (NSFC) of No. 50801054 and 50772026, and Natural Science Key Fund of Heilongjiang Province in China (grant No. ZJG0605-01).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, H.Q., Zhao, X.B., Liu, F. et al. Effect of Gd-doping on thermoelectric properties of Ca3Co4O9+δ ceramics. J Mater Sci 43, 6933–6937 (2008). https://doi.org/10.1007/s10853-008-2990-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-2990-6