Abstract

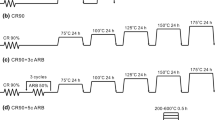

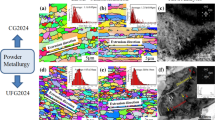

Due to structural and textural heterogeneities and a high content of stored energy, annealing of nanostructured metals is difficult to control in order to avoid non-uniform coarsening and recrystallization. The present research demonstrates a method to homogenize the structure by annealing at low temperature before annealing at high temperature. By this two-step process, the structure is homogenized and the stored energy is reduced significantly during the first annealing step. As an example, high-purity aluminum has been deformed to a total reduction of 98.4% (equivalent strain of 4.8) by accumulative roll-bonding at room temperature. Isochronal annealing for 0.5 h of the deformed samples shows the occurrence of recrystallization at 200 °C and above. However, when introducing an annealing step for 6 h at 175 °C, no significant recrystallization is observed and relatively homogeneous structures are obtained when the samples afterwards are annealed at higher temperatures up to 300 °C. To underpin these observations, the structural evolution has been characterized by transmission electron microscopy, showing that significant annihilation of high-angle boundaries, low-angle dislocation boundaries, and dislocations characterizes the low-temperature annealing step. In a discussion, the observed annealing behavior is related to these structural changes.

Similar content being viewed by others

References

Altan BS, Miskioglu I, Purcek G, Mulyukov RR, Artan R (2006) Severe plastic deformation: towards bulk production of nanostructured materials. NOVA Science Publishers, New York

Valiev RZ, Islamgaliev RK, Alexandrov IV (2000) Prog Mater Sci 45:103. doi:https://doi.org/10.1016/S0079-6425(99)00007-9

Valiev RZ, Langdon TG (2006) Prog Mater Sci 51:881. doi:https://doi.org/10.1016/j.pmatsci.2006.02.003

Horita Z et al (1996) J Mater Res 11:1880. doi:https://doi.org/10.1557/JMR.1996.0239

Segal VM (1995) Mater Sci Eng A 197:157. doi:https://doi.org/10.1016/0921-5093(95)09705-8

Iwahashi Y, Wang J, Horita Z, Nemoto M, Langdon TG (1996) Scr Mater 35:143. doi:https://doi.org/10.1016/1359-6462(96)00107-8

Saito Y, Utsunomiya H, Tsuji N, Sakai T (1999) Acta Mater 47:579. doi:https://doi.org/10.1016/S1359-6454(98)00365-6

Tsuji N, Kamikawa N, Kim HW, Minamino Y (2004) Ultrafine grained materials III. TMS, Ohio, p 219

Meyers MA, Mishra A, Benson DJ (2006) Prog Mater Sci 51:427. doi:https://doi.org/10.1016/j.pmatsci.2005.08.003

Tsuji N, Ito Y, Saito Y, Minamino Y (2002) Scr Mater 47:893. doi:https://doi.org/10.1016/S1359-6462(02)00282-8

Li BL, Godfrey A, Meng QC, Liu Q, Hansen N (2004) Acta Mater 52:1069. doi:https://doi.org/10.1016/j.actamat.2003.10.040

Wang YM et al (2004) Scr Mater 51:1023. doi:https://doi.org/10.1016/j.scriptamat.2004.08.015

Yu CY, Kao PW, Chang CP (2005) Acta Mater 53:4019. doi:https://doi.org/10.1016/j.actamat.2005.05.005

Xing ZP, Kang SB, Kim HW (2002) J Mater Sci 37:717. doi:https://doi.org/10.1023/A:1013879528697

Terada D, Inoue S, Tsuji N (2007) J Mater Sci 42:1673. doi:https://doi.org/10.1007/s10853-006-0909-7

Wang J et al (1996) Acta Mater 44:2973. doi:https://doi.org/10.1016/1359-6454(95)00395-9

Hasegawa H et al (1999) Mater Sci Eng A 265:188. doi:https://doi.org/10.1016/S0921-5093(98)01136-8

Cao WQ, Godfrey A, Hansen N, Liu Q, Metall Mater Trans, accepted for publication

Prangnell PB, Hayes JS, Bowen JR, Apps PJ, Bate PS (2004) Acta Mater 52:3193. doi:https://doi.org/10.1016/j.actamat.2004.03.019

Jazaeri H, Humphreys FJ (2004) Acta Mater 52:3251. doi:https://doi.org/10.1016/j.actamat.2004.03.031

Kamikawa N, Tsuji N, Huang X, Hansen N (2006) Acta Mater 54:3055. doi:https://doi.org/10.1016/j.actamat.2006.02.046

Li XL, Liu W, Godfrey A, Juul Jensen D, Liu Q (2007) Acta Mater 55:3531. doi:https://doi.org/10.1016/j.actamat.2007.02.005

Kamikawa N, Tsuji N, Huang X, Hansen N, Minamino Y (2006) Mater Sci Forum 512:91

Liu Q (1994) J Appl Cryst 27:755. doi:https://doi.org/10.1107/S0021889894002062

Kamikawa N, Tsuji N, Huang X, Hansen N (2007) Mater Trans 48:1978. doi:https://doi.org/10.2320/matertrans.MA200702

Hughes DA, Hansen N (2000) Acta Mater 48:2985. doi:https://doi.org/10.1016/S1359-6454(00)00082-3

Liu Q, Huang X, Lloyd DJ, Hansen N (2002) Acta Mater 50:3789. doi:https://doi.org/10.1016/S1359-6454(02)00174-X

Humphreys FJ, Hatherly M (1995) Recrystallization and related annealing behavior. Pergamon, New York

Nazarov AA, Romanov AE, Valiev RZ (1993) Acta Metall Mater 41:1033. doi:https://doi.org/10.1016/0956-7151(93)90152-I

Lian J, Valiev RZ, Baudelet B (1995) Acta Metall Mater 43:4165. doi:https://doi.org/10.1016/0956-7151(95)00087-C

Horita Z et al (1996) Mater Charact 37:285. doi:https://doi.org/10.1016/S1044-5803(96)00178-7

Valiev RZ (2003) Adv Eng Mater 5:296. doi:https://doi.org/10.1002/adem.200310089

Hansen N, Huang X, Møller MG, Godfrey A (2008) J Mater Sci. doi:https://doi.org/10.1007/s10853-008-2874-9

Acknowledgements

The authors gratefully acknowledge the Danish National Research Foundation for supporting the Center for Fundamental Research: Metal Structures in Four Dimension, within which this work was performed. The authors also thank Prof. B. Ralph for useful comments and language correction.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kamikawa, N., Huang, X. & Hansen, N. Tailoring structures through two-step annealing process in nanostructured aluminum produced by accumulative roll-bonding. J Mater Sci 43, 7313–7319 (2008). https://doi.org/10.1007/s10853-008-2964-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-2964-8