Abstract

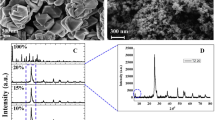

Functional titania coatings on glass microballoons (GMBs) and cenospheres have a broad range of potential environmental applications, primarily in purification of drinking water and treatment of industrial wastewater. The heterogeneous photocatalytic capabilities of titania films and particles have been extensively examined in the literature as effective alternatives to current technologies. Although the chemistry of titania films for photocatalysis has been studied, titania-coated GMBs have not yet been extensively considered and the materials science aspects of the titania-GMB and titania-cenosphere systems have not been addressed. We have examined the microstructure, morphology, and mechanical properties of titania coatings on both cenospheres and commercially produced GMBs. Scanning electron microscopy was used to examine coating coverage and defects. Energy dispersive X-ray spectroscopy and Raman spectroscopy were used for element and phase identification, respectively. Hardness and modulus measurements of the titania coatings and the GMB and cenosphere materials were done by nanoindentation. Additionally, the photocatalytic activity of the titania-coated GMB system was tested on Procion Red dye using two different types of mixing, a magnetic stirrer and an aeration bubbler apparatus. The titania coatings showed good coverage and retention except in the case of magnetic stirring, where significant coating loss was observed.

Similar content being viewed by others

References

Carlisle K, Chawla KK, Gladysz G, Koopman M (2006) J Mater Sci A 41:3961. doi:https://doi.org/10.1007/s10853-006-7571-y

Herrmann J (1999) Catal Today 53:115. doi:https://doi.org/10.1016/S0920-5861(99)00107-8

Gelover S, Gomez L, Reyes K, Leal T (2006) Water Res 40:3274. doi:https://doi.org/10.1016/j.watres.2006.07.006

Kumar S, Fedorov A, Gole J (2005) Appl Catal Environ 57:93. doi:https://doi.org/10.1016/j.apcatb.2004.10.012

Assabane A, Ichou Y, Tahiri H, Guillard C, Hermann J (2000) J Appl Catal Environ 24:71. doi:https://doi.org/10.1016/S0926-3373(99)00094-6

Visnescu C, Sanijines R, Levy F, Parvulescu V (2005) Appl Catal Environ 60:155. doi:https://doi.org/10.1016/j.apcatb.2005.02.029

Nair M, Zhenhao L, Heller A (1993) Ind Eng Chem Res 32:2318. doi:https://doi.org/10.1021/ie00022a015

Krichevskaya M, Malygina T, Peis S, Kallas J (2001) Water Sci Technol 44:1

Petrowski J, Bulska A, Jozwiak W (2005) Environ Protein Eng 31:61

Stokke J, Mazyck D, Wu C, Sheahan R (2006) Environ Prog 25:312. doi:https://doi.org/10.1002/ep.10164

Faisal M, Tariq M, Muneer M (2007) Dyes Pigments 72:233. doi:https://doi.org/10.1016/j.dyepig.2005.08.020

Yu J, Ho W, Yu J, Yip H, Wong P, Zhao J (2005) Environ Sci Technol 39:1175. doi:https://doi.org/10.1021/es035374h

Christensen P, Curtis T, Egerton T, Kosa S, Timlin J (2003) Appl Catal Environ 41:371. doi:https://doi.org/10.1016/S0926-3373(02)00172-8

Shifu C, Gengyu C (2005) Sol Energy 79:1. doi:https://doi.org/10.1016/j.solener.2004.10.006

Preis S, Krichevskaya M, Karchenko A (1997) Water Sci Technol 35:265. doi:https://doi.org/10.1016/S0273-1223(97)00034-6

Carlisle K, Lewis M, Chawla KK, Koopman M, Gladysz G (2007) Acta Mater 55:2301. doi:https://doi.org/10.1016/j.actamat.2006.11.026

Bockmeyer M, Lohmann P (2007) Thin Solid Films 515:5212. doi:https://doi.org/10.1016/j.tsf.2006.11.193

Jagtap N, Bhagwat M, Awati P, Ramawamy V (2005) Thermochim Acta 427:37. doi:https://doi.org/10.1016/j.tca.2004.08.011

Haldimann M (2006) Fracture strength of structural glass elements—analytical and numerical modeling, testing and design, dissertation 3671 de Ecole Polytechnique Federale de Lausanne, Lausanne, Switzerland

Chawla KK (1998) Composite materials, 2nd edn. Springer, New York

Gouadec G, Colomban P (2007) Prog Cryst Growth Character Mater 55:1. doi:https://doi.org/10.1016/j.pcrysgrow.2007.01.001

Lee J, Kong S, Kim W, Kim J (2007) Mater Chem Phys 106:39. doi:https://doi.org/10.1016/j.matchemphys.2007.05.019

Sanz J, Soriano L, Prieto P, Tyuliev G, Morant C, Elizalde E (1998) Thin Solid Films 332:209. doi:https://doi.org/10.1016/S0040-6090(98)01058-X

Gao X, Wachs L (1999) Catal Today 51:233. doi:https://doi.org/10.1016/S0920-5861(99)00048-6

Chiu K, Wong M, Cheng F, Manan H (2007) Appl Surf Sci 253:6762. doi:https://doi.org/10.1016/j.apsusc.2007.01.121

Olofinjana A, Bell J, Jamting A (2000) Wear 241:174. doi:https://doi.org/10.1016/S0043-1648(00)00372-0

Boccaccini A, Acevedo D, Brusatin G, Colombo P (2005) J Eur Ceram Soc 25:1515. doi:https://doi.org/10.1016/j.jeurceramsoc.2004.05.015

Matsunaga T, Kim I, Hardcastele S, Rohatgi P (2002) Mater Sci Eng A 352:333. doi:https://doi.org/10.1016/S0921-5093(01)01466-6

Lachheb H, Puzenat E, Houas E, Ksibi M, Elalouil E, Guillard G, Herrmann J (2002) Appl Catal Environ 39:75. doi:https://doi.org/10.1016/S0926-3373(02)00078-4

So C, Cheng M, Yu J, Wang P (2002) Chemosphere 46:905. doi:https://doi.org/10.1016/S0045-6535(01)00153-9

Byrne J, Eggins B, Brown M, Mckinney B, Rouse M (1998) Appl Catal Environ 17:25–1. doi:https://doi.org/10.1016/S0926-3373(97)00101-X

Rachel A, Subrahmanyam M, Bourle P (2002) Appl Catal Environ 37:301. doi:https://doi.org/10.1016/S0926-3373(02)00007-3

Kontos AI, Kontos AG, Tsoukleris D, Vlachos G, Flaras P (2007) Thin Solid Films 515:7370. doi:https://doi.org/10.1016/j.tsf.2007.02.082

Acknowledgements

The authors gratefully acknowledge support from the National Science Foundation for their Research Experience for Undergraduates program, as well as a UAB Framework for Global Health Grant, which both supported portions of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Koopman, M., Chawla, K.K., Ricci, W. et al. Titania-coated glass microballoons and cenospheres for environmental applications. J Mater Sci 44, 1435–1441 (2009). https://doi.org/10.1007/s10853-008-2963-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-2963-9