Abstract

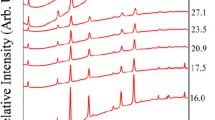

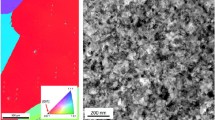

Pure and dense nanocrystalline MgO with grain size ranging between 25 and 500 nm were prepared by hot-pressing. Vickers microhardness was found to increase with decrease in the grain size down to 130 nm, following the Hall–Petch relation. Further decrease in the grain size was followed by continuous decrease in microhardness. A composite model was used to describe the microhardness behavior in terms of plastic yield of the nanocrystalline grains accompanied by strain accommodation and nanocracking at the grain boundaries (gb’s). Good agreement between the experimental and the calculated values indicates that gb’s may have significant effect on strengthening and ductility of nanocrystalline-MgO ceramics in the nanometer size range. Critical grain size exists below which limited plastic deformation within the grains and nanocracking at gb’s enhance the brittleness of the ceramic.

Similar content being viewed by others

References

Morgan PED, Scala E (1965) In: Kuczynski GC, Hooton NA, Gibbon CF (eds) Sintering and related phenomena. Breach Sci Pub, NY

Pampush R (1979) Ceramurgia Int 5:76

Itatani K, Nomura M, Kishioka A, Kinoshita M (1986) J Mater Sci 21:1429. doi:https://doi.org/10.1007/BF00553284

Itatani K, Yasuda R, Howell FS, Kishioka A (1997) J Mater Sci 32:2977. doi:https://doi.org/10.1023/A:1018649222749

Vieira JM, Brook RJ (1984) J Am Ceram Soc 67:450

Pampush R, Tomaszewski H, Haberko K (1975) Ceramurgia Int 1:81

Wilshire B (1995) Br Ceram Trans 94:57

Ehre D, Gutmanas EY, Chaim R (2005) J Eur Ceram Soc 25:3579

Chaim R, Shen Z, Nygren M (2004) J Mater Res 19:2527

Rice RW, Wu CC, Borchelt F (1994) J Am Ceram Soc 77:2539

Majumdar BS, Burns SJ (1987) J Mater Sci 22:1157. doi:https://doi.org/10.1007/BF01233104

Chokshi AH, Rosen A, Karch J, Gleiter H (1989) Scripta Metall 23:1679

Jang JSC, Koch CC (1990) Scripta Metall Mater 24:1599

Lu K, Wei WD, Wang JT (1990) Scripta Metall Mater 24:2319

Gerstman VY, Hoffmann M, Gleiter H, Birringer R (1994) Acta Mater 42:3539

Nieh TG, Wadsworth J (1991) Scripta Metall Mater 25:955

Lian J, Baudelet B (1993) Nanostruct Mater 2:415

Wang N, Wang Z, Aust KT, Erb U (1995) Acta Metall Mater 43:519

Masumura RA, Hazzeldine PM, Pande CS (1998) Acta Mater 46:4527

Song HW, Guo SR, Hu ZQ (1999) Nanostruct Mater 11:203

Zaichenko SG, Glezer AM (1999) Interface Sci 7:57

Singh RN, Coble RL (1974) J Appl Phys 45:981

Auten TA, Radcliffe SV, Gordon RB (1976) J Am Ceram Soc 59:40

Bahr DF, Kramer DE, Gerberich WW (1998) Acta Mater 46:3605

Gaillard Y, Tromas C, Woirgard J (2004) Acta Mater 54:1409

Chattopadhyay PP, Pabi SK, Manna I (2001) Mater Chem Phys 68:80

Kennard FL, Bradt RC, Stubican VS (1976) J Am Ceram Soc 59:160

Loubet JL, Georges JM, Marcheshini O, Meille G (1984) J Tribol 106:43

Higashida K, Narita N, Onodera R, Minato S, Okazaki S (1997) Mater Sci Eng A 237:72

Wolff U, Pryds N, Johnson E, Wert JA (2004) Acta Mater 52:1989

Baricco M, Castellero A, Di Chio M et al (2007) J Alloys Compd 434–435:183

Wang HL, Lin CH, Hon MH (1997) Thin Solid Films 310:260

Li Q, Yu YH, Bhatia CS, Marks LD et al (2000) J Vac Sci Technol A 18:2333

Yeheskel O, Chaim R, Shen Z, Nygren M (2005) J Mater Res 20:719

Hammond BL, Armstrong RW (1988) Phil Mag Lett 57:41

Sangwal K, Gorostiza P, Servat J, Sanz F (1999) J Mater Res 14:3973

Bush MB (1993) Mater Sci Eng A 161:127

Chaim R (1997) J Mater Res 12:1828

Cook RF, Pharr GM (1990) J Am Ceram Soc 73:787

Larsson PL, Giannakopoulos AE (1998) Mater Sci Eng A 254:268

McColm IJ (1990) Ceramic hardness. Plenum, New York

Roberts SG (1988) Phil Mag A 58:347

Cook RF, Liniger EG (1992) J Mater Sci 27:4751. doi:https://doi.org/10.1007/BF01166017

Rice RW (1971) In: Kriegel WW, Palmour H III (eds) Materials science research. Plenum Press, NY

Zhang J, Sakai M (2004) Mater Sci Eng A 381:62

Wang N, Palumbo G, Wang Z, Erb U, Aust KT (1993) Scripta Metall Mater 28:253

Acknowledgement

The support of the Israel Ministry of Science through the grant no. 1090-1-00 is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ehre, D., Chaim, R. Abnormal Hall–Petch behavior in nanocrystalline MgO ceramic. J Mater Sci 43, 6139–6143 (2008). https://doi.org/10.1007/s10853-008-2936-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-2936-z