Abstract

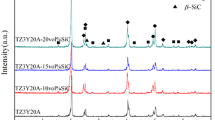

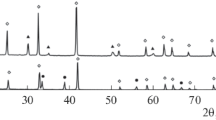

Y2O3 + Nd2O3 co-stabilized ZrO2-based composites with 40 vol% WC were fully densified by pulsed electric current sintering (PECS) at 1350 °C and 1450 °C. The influence of the PECS temperature and Nd2O3 co-stabilizer content on the densification, hardness, fracture toughness and bending strength of the composites was investigated. The best combination of properties was obtained for a 1 mol% Y2O3 and 0.75 mol% Nd2O3 co-stabilized composite densified for 2 min at 1450 °C under a pressure of 62 MPa, resulting in a hardness of 15.5 ± 0.2 GPa, an excellent toughness of 9.6 ± 0.4 MPa.m0.5 and an impressive 3-point bending strength of 2.04 ± 0.08 GPa. The hydrothermal stability of the 1 mol% Y2O3 + 1 mol% Nd2O3 co-stabilized ZrO2-WC (60/40) composites was compared with that of the equivalent 2 mol% Y2O3 stabilized ceramic. The double stabilized composite did not degrade in 1.5 MPa steam at 200 °C after 4000 min, whereas the yttria stabilized composite degraded after less than 2000 min. Moreover, the (1Y,1Nd) ZrO2-WC composites have a substantially higher toughness (~9 MPa.m0.5) than their 2Y stabilized equivalents (~7 MPa.m0.5).

Similar content being viewed by others

References

Hannink RHJ, Kelly PM, Muddle BC (2000) J Am Ceram Soc 83:461

Bonny K, De Baets P, Vleugels J, Salehi A, Van der Biest O, Lauwers B et al, J Mat Proc Tech (in press)

Lauwers B, Brans K, Liu W, Vleugels J, Salehi S, Vanmeensel K (2008) CIRP Ann Manu Tech 57:191. doi:https://doi.org/10.1016/j.cirp.2008.03.089

Salehi S, Van der Biest O, Vleugels J (2006) J Eur Ceram Soc 26:3173. doi:https://doi.org/10.1016/j.jeurceramsoc.2005.10.010

Salehi S, Van der Biest O, Brans K, Vleugels J (2008) J Am Ceram Soc (submitted)

Vleugels J, Van Der Biest O (1999) J Am Ceram Soc 82:2717

Basu B, Vleugels J, Van der Biest O (2005) J Eur Ceram Soc 25:3629. doi:https://doi.org/10.1016/j.jeurceramsoc.2004.09.017

Jiang D, Van der Biest O, Vleugels J (2007) J Eur Ceram Soc 27:1247. doi:https://doi.org/10.1016/j.jeurceramsoc.2006.05.028

Huang SG, Vanmeensel K, Van der Biest O, Vleugels J (2007) J Eur Ceram Soc 27:3269. doi:https://doi.org/10.1016/j.jeurceramsoc.2006.11.079

Anné G, Put S, Vanmeensel K, Jiang D, Vleugels J, Van der Biest O (2005) J Eur Ceram Soc 25:55. doi:https://doi.org/10.1016/j.jeurceramsoc.2004.01.015

Lawson S (1995) J Eur Ceram Soc 15:485. doi:https://doi.org/10.1016/0955-2219(95)00035-S

Chevalier J, Cales B, Drouin J (1999) J Am Ceram Soc 82:2150

Salehi S, Vanmeensel K, Van der Biest O, Vleugels J (2008) J Am Ceram Soc (submitted)

Yuan ZX, Vleugels J, Van der Biest O (2000) J Mater Sci Lett 19:359. doi:https://doi.org/10.1023/A:1006714032131

Vanmeensel K, Laptev A, Hennicke J, Vleugels J, Van der Biest O (2005) Acta Mater 53:4379. doi:https://doi.org/10.1016/j.actamat.2005.05.042

Toraya H, Yoshimura M, Somiya S (1984) J Am Ceram Soc 67:C119. doi:https://doi.org/10.1111/j.1151-2916.1984.tb19614.x

Anstis GR, Chantikul P, Lawn BR, Marshall DB (1981) J Am Ceram Soc 64:533. doi:https://doi.org/10.1111/j.1151-2916.1981.tb10320.x

ASTM Standard E 1876-99 (1994) ASTM Annual Book of Standards, Philadelphia, PA

Moskała N, Pyda W (2006) J Eur Ceram Soc 26:3845. doi:https://doi.org/10.1016/j.jeurceramsoc.2005.12.012

Wang J, Stevens R (1989) J Mater Sci 24:3424

Awaji H, Choi SM, Yagi E (2002) Mech Mater 34:411. doi:https://doi.org/10.1016/S0167-6636(02)00129-1

Evans AG, Faber KT (1981) J Am Ceram Soc 64:394. doi:https://doi.org/10.1111/j.1151-2916.1981.tb09877.x

Shannon RD (1976) Acta Crystallogr 32:751. doi:https://doi.org/10.1107/S0567739476001551

Rey JFQ, Muccillo ENS (2004) J Eur Ceram Soc 24:1287. doi:https://doi.org/10.1016/S0955-2219(03)00498-9

Acknowledgements

S. Salehi thanks the Research Council of K.U.Leuven for a doctoral scholarship (DB/07/012). This work was supported by the Commission of the European Communities within the 6th Framework Program under project No. STRP 505541–1.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Salehi, S., Van der Biest, O. & Vleugels, J. Y2O3 and Nd2O3 co-stabilized ZrO2-WC composites. J Mater Sci 43, 5784–5789 (2008). https://doi.org/10.1007/s10853-008-2899-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-2899-0