Abstract

The processing of a magnesium AZ31 alloy by equal-channel angular pressing refines the grain size to ~2.2 μm, but annealing for 30 min at 673 K coarsens the grains to ~6.0 μm. Despite this microstructural instability, the alloy is superplastic when pulled in tension at temperatures in the range of 623–723 K with elongations up to >1000% at strain rates at and below 10−4 s−1. Experiments within the superplastic regime show the strain rate sensitivity is ~0.5 and the activation energy is close to the value for grain boundary diffusion. It is demonstrated by calculation that the experimental results are in good agreement with a model for superplasticity based on grain boundary sliding.

Similar content being viewed by others

References

Valiev RZ, Langdon TG (2006) Prog Mater Sci 51:881. doi:https://doi.org/10.1016/j.pmatsci.2006.02.003

Langdon TG (1982) Metall Trans 13A:689

Xu C, Horita Z, Furukawa M, Langdon TG (2004) J Mater Eng Perform 13:683. doi:https://doi.org/10.1361/10599490421385

Kawasaki M, Figueiredo RB, Xu C, Langdon TG (2007) Metall Mater Trans 38A:1891

Kawasaki M, Langdon TG (2007) J Mater Sci 42:1782. doi:https://doi.org/10.1007/s10853-006-0954-2

Furui M, Kitamura H, Anada H, Langdon TG (2007) Acta Mater 55:1083. doi:https://doi.org/10.1016/j.actamat.2006.09.027

Lapovok R, Cottam R, Thomson PF, Estrin Y (2005) J Mater Res 20:1375. doi:https://doi.org/10.1557/JMR.2005.0180

Lapovok R, Thomson PF, Cottam R, Estrin Y (2005) Mater Sci Eng A 410–411:390. doi:https://doi.org/10.1016/j.msea.2005.08.067

Figueiredo RB, Langdon TG (2008) Adv Eng Mater 10:37. doi:https://doi.org/10.1002/adem.200700315

Myahara Y, Horita Z, Langdon TG (2006) Mater Sci Eng A 420:240. doi:https://doi.org/10.1016/j.msea.2006.01.043

Mabuchi M, Ameyama K, Iwasaki H, Higashi K (1999) Acta Mater 47:2047. doi:https://doi.org/10.1016/S1359-6454(99)00094-4

Lin HK, Huang JC, Langdon TG (2005) Mater Sci Eng A 402:250. doi:https://doi.org/10.1016/j.msea.2005.04.018

Watanabe H, Takara A, Somekawa H, Mukai T, Higashi K (2005) Scr Mater 52:449. doi:https://doi.org/10.1016/j.scriptamat.2004.11.011

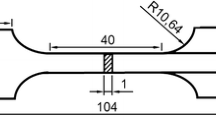

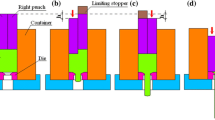

Iwahashi Y, Wang J, Horita Z, Nemoto M, Langdon TG (1996) Scr Mater 35:143. doi:https://doi.org/10.1016/1359-6462(96)00107-8

Furukawa M, Iwahashi Y, Horita Z, Nemoto M, Langdon TG (1998) Mater Sci Eng A 257:328. doi:https://doi.org/10.1016/S0921-5093(98)00750-3

Vagarali SS, Langdon TG (1982) Acta Metall 30:1157. doi:https://doi.org/10.1016/0001-6160(82)90009-8

Jin L, Dongliang L, Mao D, Zeng X, Ding W (2006) J Alloy Comp 426:148. doi:https://doi.org/10.1016/j.jallcom.2006.02.018

Su CW, Lu L, Lai MO (2006) Mater Sci Eng A 434:227. doi:https://doi.org/10.1016/j.msea.2006.06.103

Kim HK, Kim WJ (2004) Mater Sci Eng A 385:300

Xia K, Wang JT, Wu X, Chen G, Gurvan M (2005) Mater Sci Eng A 410–411:324. doi:https://doi.org/10.1016/j.msea.2005.08.123

Zuberová Z, Estrin Y, Lamark TT, Janecek M, Hellmig RJ, Krieger M (2007) J Mater Proc Tech 184:294. doi:https://doi.org/10.1016/j.jmatprotec.2006.11.098

Janecek M, Popov M, Krieger MG, Hellmig RJ, Estrin Y (2007) Mater Sci Eng A 462:116. doi:https://doi.org/10.1016/j.msea.2006.01.174

Langdon TG (1994) Mater Sci Eng A 174:225. doi:https://doi.org/10.1016/0921-5093(94)91092-8

Valiev RZ, Langdon TG (1993) Acta Metall Mater 41:949. doi:https://doi.org/10.1016/0956-7151(93)90029-R

Langdon TG (1994) Acta Metall Mater 42:2437. doi:https://doi.org/10.1016/0956-7151(94)90322-0

Frost HJ, Ashby MF (1982) Deformation-Mechanism Maps: The Plasticity and Creep of Metals and Ceramics. Pergamon Press, Oxford, UK

Somekawa H, Hosokawa H, Watanabe H, Higashi K (2003) Mater Sci Eng A 339:328. doi:https://doi.org/10.1016/S0921-5093(02)00127-2

del Valle JA, Carreño F, Ruano OA (2007) Scr Mater 57:829. doi:https://doi.org/10.1016/j.scriptamat.2007.07.002

Langdon TG (2002) Metall. Mater Trans 33A:249

del Valle JA, Pérez-Prado MT, Ruano OA (2005) Metall. Mater Trans 36A:1427

Acknowledgements

One of the authors (RBF) was supported by a CAPES/Fulbright Scholarship. This work was supported by the U.S. Army Research Office under Grant No. W911NF-05-1-0046.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Figueiredo, R.B., Langdon, T.G. Developing superplasticity in a magnesium AZ31 alloy by ECAP. J Mater Sci 43, 7366–7371 (2008). https://doi.org/10.1007/s10853-008-2846-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-2846-0