Abstract

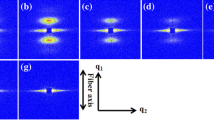

The influence of draw ratios (DR) of gel-spun ultrahigh molecular weight polyethylene (UHMWPE) fibers on resultant morphologies, tensile, degrees of orientation, and crystal phase transition properties were investigated using wide-angle X-ray diffraction (WAXD), differential scanning calorimetry (DSC), and scanning electron microscopy (SEM). The anisotropic crystalline structure with full concentric circular rings originally shown on the WAXD patterns of the as-prepared and drawn UHMWPE fibers gradually transform into oriented fibers with azimuthal spots on the equator as their DR values increase from 1 to 20, in which their orthorhombic crystals, percentage crystallinity, crystalline orientation, and the birefringence values increase significantly. As evidenced by SEM and WAXD analysis, the chain-folded molecules originally present in kebab crystals of the as-prepared UHMWPE fiber specimens gradually transformed into shish-like crystals with relatively high orientation as their DR values increase from 1 to 20. In contrast, the crystallinity and crystal orientation values of the drawn UHMWPE specimens increase only slightly, as their DR values increase from 20 to 40, wherein both crystallinity values of orthorhombic and monoclinic crystals increase slightly. In fact, barely any oriented kebab but only shish crystals were observed on the surfaces of drawn UHMWPE fiber specimens with DR values higher than 20. The birefringence values increase only slightly with further increasing DR values, while crystallinity and crystal orientation values of the drawn UHMWPE fiber specimens remained relatively unchanged as their DR values increase from 40 to 150. In the meantime, the monoclinic crystals gradually grow at the expense of the orthorhombic form crystals as the DR values of drawn UHMWPE fiber specimens increase from 40 to 150. Possible reasons accounting for these interesting properties found for the drawn UHMWPE fibers with varying draw ratios are proposed in this study.

Similar content being viewed by others

References

Smith P, Lemstra PJ (1979) Macromol Chem 180:2983. doi:https://doi.org/10.1002/macp.1979.021801220

Barham PJ, Leller A (1985) J Mater Sci 20:2281. doi:https://doi.org/10.1007/BF00556059

Ward IM (1995) Macromol Symp 100:1

Poter RS (1980) Chem Rev 80:351. doi:https://doi.org/10.1021/cr60326a005

Rudin A, Tchir WJ, Gagnon R, Schreiber HP, Collacoot R (1989) Ind Eng Chem Res 28:174. doi:https://doi.org/10.1021/ie00086a008

Mooen JA, Kip BJ (1992) J Polym Sci Part B: Polym Phys 30:361. doi:https://doi.org/10.1002/polb.1992.090300406

Riekel C, Cedola A, Heidelbach F, Wagner K (1997) Macromolecules 30:1033. doi:https://doi.org/10.1021/ma960799s

Yang L, Somani RH, Sics I, Hsiao BS, Kolb R, Fruitwala H, Ong C (2004) Macromolecules 37:4845. doi:https://doi.org/10.1021/ma049925f

Russel KE, Heyding RD (1997) Polymer 38:1409. doi:https://doi.org/10.1016/S0032-3861(96)00643-X

Nakae M, Uehara H, Kanamoto T, Zachariades AE, Porter RS (2000) Macromolecules 33:2632. doi:https://doi.org/10.1021/ma991330a

Hu XP, Hsieh YL (1998) Polym J 30:771. doi:https://doi.org/10.1295/polymj.30.771

Hsieh YL, Ju J (1994) J Appl Polym Sci 53:347. doi:https://doi.org/10.1002/app.1994.070530312

Ratner S, Weinberg A, Maron G (2003) Polym Compos 24:422. doi:https://doi.org/10.1002/pc.10040

Ratner S, Weinberg A, Wachtel E, Moret PM, Marom G (2004) Macromol Rapid Commun 25:1150. doi:https://doi.org/10.1002/marc.200400102

Luo C, Guardala NA, Price JL, Chodak I, Zimerman O, Weiss RG (2002) Macromolecules 35:4690. doi:https://doi.org/10.1021/ma020235q

Hu WG, Schmidit RK (2000) Polymer 41:2979. doi:https://doi.org/10.1016/S0032-3861(99)00429-2

Rotzinger BP, Chanzy HD, Smith P (1989) Polymer 30:1814. doi:https://doi.org/10.1016/0032-3861(89)90350-9

Vanderhart DL, Khoury F (1984) Polymer 25:1589. doi:https://doi.org/10.1016/0032-3861(84)90151-4

Uehara HM, Aoike HT, Yamanobe T, Komoto T (2001) Polymer 42:5893. doi:https://doi.org/10.1016/S0032-3861(00)00911-3

Sheiko S, Frey H, Moller M (1992) Colloid Polym Sci 270:440. doi:https://doi.org/10.1007/BF00665987

Kwon YK, Boller A, Pyda M, Wunderlich B (2000) Polymer 41:6237. doi:https://doi.org/10.1016/S0032-3861(99)00839-3

Silverstein MS, Sadovsky J, Alon D, Wahad V (1999) J Appl Polym Sci 72:405. doi:10.1002/(SICI)1097-4628(19990418)72:3≤405::AID-APP10≥3.0.CO;2-I

Zhang H, Shi M, Zhang J, Wang S (2003) J Appl Polym Sci 89:2757. doi:https://doi.org/10.1002/app.12448

Yeh JT, Chang SS (2000) J Mater Sci 35:3227. doi:https://doi.org/10.1023/A:1004858902462

Yeh JT, Lin YT, Jiang HB (2003) J Appl Polym Sci 91:1559. doi:https://doi.org/10.1002/app.13259

Yeh JT, Chang SS (2001) J Appl Polym Sci 79:1890. doi:10.1002/1097-4628(20010307)79:10≤1890::AID-APP180≥3.0.CO;2-T

Yeh JT, Lin YT, Chen KN (2003) J Appl Polym Sci 89:3728. doi:https://doi.org/10.1002/app.12390

Chodak I (1998) Prog Polym Sci 23:1409. doi:https://doi.org/10.1016/S0079-6700(98)00006-9

Alon Y, Marom G (2004) Macromol Rapid Commun 25:1387. doi:https://doi.org/10.1002/marc.200400185

Yeh JT, Chang SS, Yen MS (1998) J Appl Polym Sci 70:149. doi:10.1002/(SICI)1097-4628(19981003)70:1≤149::AID-APP15≥3.0.CO;2-2

Yeh JT, Chang SS (2002) Polym Eng Sci 42:1558. doi:https://doi.org/10.1002/pen.11051

Jiang T, Shyu WD, Lin YT, Chen KN, Yeh JT (2003) Polym Eng Sci 43:1765. doi:https://doi.org/10.1002/pen.10149

Yeh JT, Lin YT, Chen KN (2003) J Polym Res 10:55. doi:https://doi.org/10.1023/A:1023961216058

Kanamoto T, Tsurta A, Tanana K, Takeda M, Porter RS (1988) Macromolecules 21:470. doi:https://doi.org/10.1021/ma00180a032

Smook J, Pennings AJ (1982) J Appl Polym Sci 27:2209. doi:https://doi.org/10.1002/app.1982.070270631

Hermans PH (1949) J Polym Sci 4:749. doi:https://doi.org/10.1002/pol.1949.120040609

Stein RS (1958) J Polym Sci 31:327. doi:https://doi.org/10.1002/pol.1958.1203112309

Lacroix FV, Schulte K (1999) Polymer 40:843. doi:https://doi.org/10.1016/S0032-3861(98)00309-7

Acknowledgements

The authors would like to express their appreciation to National Science Council (NSC 95–2221-E-253-008-MY3) and Department of Industrial Technology, Ministry of Economic Affairs (95-EC-17-A-11-S1-057) for their support of this work. Thanks are also extended to Drs. M. H. J. Koch, A. Gabriel, Y. S. Sun, and Y. H. Lai for their help in WAXS measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yeh, JT., Lin, SC., Tu, CW. et al. Investigation of the drawing mechanism of UHMWPE fibers. J Mater Sci 43, 4892–4900 (2008). https://doi.org/10.1007/s10853-008-2711-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-2711-1