Abstract

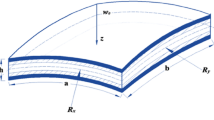

Currently, there is incomplete knowledge of the damping level and its sources in satellite structures and a suitable method to model it constitutes a necessary step for reliable dynamic predictions. As a first step of a damping characterization, the damping of honeycomb structural panels, which is identified as a main contributor to global damping, has been considered by ALCATEL SPACE. In this work, the inherent vibration damping mechanism in sandwich panels, including those with both aluminium and carbon fibre-reinforced plastic (CFRP) skins, is considered. It is first shown how the theoretical modal properties of the sandwich panel can be predicted from the stiffness and damping properties of its constituent components using the basic laminate theory, a first-order shear deformation theory and a simple discretization method. Next, a finite-element transcription of this approach is presented. It is shown to what extent this method can be implemented using a finite-element software package to predict the overall damping value of a sandwich honeycomb panel for each specific mode. Few of the many theoretical models used to predict natural frequencies of plates are supported by experimental data and even fewer for damping values. Therefore, in a second, experimental part, the Rayleigh–Ritz method and NASTRAN (finite-element software used by ALCATEL SPACE) predicted modal characteristics (frequency and damping) are compared with the experimentally obtained values for two specimens of typical aluminium core honeycomb panels (aluminium and CFRP skins) used by ALCATEL SPACE as structural panels. It is shown through these results that the method (theoretical and finite element) is satisfactory and promising.

Similar content being viewed by others

References

Maheri MR, Adams RD (2003) J Sound Vibr 259(1):17. doi:https://doi.org/10.1006/jsvi.2002.5151

Yuan WX, Dawe DJ (2002) Intl J Numer Meth Eng 54:195. doi:https://doi.org/10.1002/nme.411

Chen Q, Chan YW (2000) Comput Struct 74:51. doi:https://doi.org/10.1016/S0045-7949(98)00321-6

Noor AK, Burton WS, Bert CW (1996) Appl Mech Rev Trans ASME 49(3):155

Nayak AK, Shenoi RA, Moy SSJ (2002) IMechE, J Mech Eng Sci 216:591

Nayak AK, Moy SSJ, Shenoi RA (2003) J Strain Anal Eng Design 38:377. doi:https://doi.org/10.1243/03093240360713441

Rikards R, Chate A, Korjakin A (1995) Eng Comput 12:61

Adams RD, Maheri MR (1993) Compos Sci Technol 47(1):15. doi:https://doi.org/10.1016/0266-3538(93)90091-T

Adams RD, Maheri MR (1994) Compos Sci Technol 50(4):497. doi:https://doi.org/10.1016/0266-3538(94)90058-2

Dawe DJ, Roufaeil OL (1980) J Sound Vibr 69(3):345. doi:https://doi.org/10.1016/0022-460X(80)90477-0

Craige TJ, Dawe DJ (1986) Intl J Solid Struct 22(2):155. doi:https://doi.org/10.1016/0020-7683(86)90005-3

Adams RD, Bacon DGC (1973) J Compos Mater 7:402

Young D (1950) J Appl Mech 17:448

Ashton JE, Waddoups ME (1969) J Compos Mater 3:148. doi:https://doi.org/10.1177/002199836900300111

Ashton JE, Whitney JM (1970) Theory of laminated plates. Technomic Publishing Company, Conn, USA

Maheri MR, Adams RD (1995) Compos Sci Technol 55(1):13. doi:https://doi.org/10.1016/0266-3538(95)00074-7

Maheri MR (1991) Vibration damping in composite/honeycomb sandwich beams, PhD thesis, Department of Mechanical Engineering, University of Bristol

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

Components of the Rayleigh–Ritz stiffness matrix

Components of the Rayleigh–Ritz mass matrix

Rights and permissions

About this article

Cite this article

Maheri, M.R., Adams, R.D. & Hugon, J. Vibration damping in sandwich panels. J Mater Sci 43, 6604–6618 (2008). https://doi.org/10.1007/s10853-008-2694-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-2694-y