Abstract

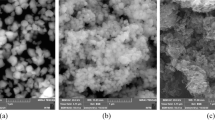

The processing of yttria-stabilised zirconia (Y-ZrO2)-based ceramic nanocomposites by means of pulsed electric current sintering (PECS) is described. A nanometer-sized electrically conductive secondary TiCN phase was added to the insulating zirconia matrix in order to make the composite electrically conductive. The paper focuses on the importance of processing conditions and highlights the benefits of the PECS method as compared to more traditional hot pressing. The mechanical and microstructural properties of the ZrO2–TiCN composites have been determined, and the benefits of using an electrical current to densify these composites were explained in terms of the evolution of the electrical properties of the densifying powder compact.

Similar content being viewed by others

References

Garvie RC, Hannink RHJ, Pascoe RT (1975) Nature 258:703

Hannink RHJ, Kelly PM, Muddle BC (2000) J Am Ceram Soc 83:461

Basu B, Vleugels J, Van der Biest O (2002) Key Eng Mater 206–213:1177

Huang SG, Vanmeensel K, Van der Biest O, Vleugels J (2007) J Eur Ceram Soc 27:3269

Basu B, Vleugels J, Van der Biest O (2002) J Alloys Compd 334:200

Vleugels J, Van der Biest O (1999) J Am Ceram Soc 82:2717

Vanmeensel K, Sastry KY, Laptev A, Vleugels J, Van der Biest O (2005) Solid State Phenom 106:153

Salehi S, Van der Biest O, Vleugels J (2006) J Eur Ceram Soc 26(15):3173

Rul S, Lefevre-Schlick F, Capria E, Laurent C, Peigney A (2004) Acta Mater 52:1061

Jiang D, Van der Biest O, Vleugels J (2007) J Eur Ceram Soc 27:1247

Duan RG, Kuntz JD, Garay JE, Mukherjee AK (2004) Scripta Mater 50:1309

Kawano S, Takahashi J, Shimada S (2004) J Eur Ceram Soc 24:309

Mayo MJ (2000) Adv Eng Mater 2:409

Guo Z, Blugan G, Kirchner R, Reece M, Graule T, Kuebler J (2007) Ceram Int 33:1223

Kear BH, Colaizzi J, Mayo WE, Liao SC (2001) Scripta Mater 44:2065

Angerer P, Yu LG, Khor KA, Krumpel G (2004) Mater Sci Eng A 381:16

Nygren M, Shen Z (2003) Solid State Sci 5:125

Basu B, Vleugels J, Van der Biest O (2004) Mater Sci Eng A 380:215

Vanmeensel K, Laptev A, Hennicke J, Vleugels J, Van der Biest O (2005) Acta Mater 53:4379

Anstis GR, Chantikul P, Lawn BR, Marshall DB (1981) J Am Ceram Soc 64:533

Roebben G, Basu B, Vleugels J, Van Humbeeck J, Van der Biest O (2000) J Alloys Compd 310:284

Toraya H, Yoshimura M, Somiya S (1984) J Am Ceram Soc 67:C119

Bánhegyi G (1986) Colloid Polym Sci 264:1030

Vanmeensel K, Laptev A, Van der Biest O, Vleugels J (2007) Acta Mater 55:1401

Sandler JKW, Kirk JE, Kinloch IA, Shaffer MSP, Windle AH (2003) Polymer 44:5893

Acknowledgements

This work was performed within the framework of the Research Fund of K.U.Leuven under project GOA/08/007 and FWO project grant number 3E060133. K. Vanmeensel thanks the Fund for Scientific Research Flanders (FWO), S. Salehi thanks the Research Council of K.U.Leuven for a doctoral scholarship (DB/07/012) and A Laptev acknowledges the Research Council of K.U.Leuven for his research fellowship. The authors also acknowledge the support of the Belgian Federal Science Policy Office (BELSPO) through the NACER project (contract P2/00/07).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vanmeensel, K., Huang, S.G., Laptev, A. et al. Pulsed electric current sintering of electrically conductive ceramics. J Mater Sci 43, 6435–6440 (2008). https://doi.org/10.1007/s10853-008-2631-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-2631-0