Abstract

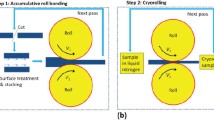

The microstructure evolution upon annealing of 1100 aluminum samples that were accumulative roll bonding (ARB) processed were studied with the use of transmission electron microscopy. It was found that the ultra-fine microstructure resulted from the ARB process was not stable. Specifically, a two-stage grain growth behavior was observed, in which a relatively slower rate of grain growth was followed by a more rapid grain growth rate at higher annealing temperature. The bonding interfaces that were unique to the roll bonding process were found to have a significant influence on the grain growth behavior when the grain size of the material was of similar dimension as the bonding interface separation. Discontinuous pockets consisting of smaller grains were found to have formed upon annealing. These pockets represented the remnants of the heavily deformed layer from wire brushing.

Similar content being viewed by others

References

Saito Y, Tsuji N, Utsunomiya H, Sakai T, Hong RG (1998) Scr Mater 39:1221. doi:https://doi.org/10.1016/S1359-6462(98)00302-9

Saito Y, Utsunomiya H, Tsuji N, Sakai T (1999) Acta Mater 47:579. doi:https://doi.org/10.1016/S1359-6454(98)00365-6

Vaidyanath LR, Milner DR (1960) Brit Weld J 7:1

Clemensen C, Juelstorp O, Bay N (1986) Metal Constr 18:625

Nicholas MG, Milner DR (1961) Brit Weld J 8:375

Xing ZP, Kang SB, Kim HW (2004) J Mater Sci 39:1259. doi:https://doi.org/10.1023/B:JMSC.0000013884.69611.72

Xing ZP, Kang SB, Kim HW (2002) Metall Mater Trans A 33:1521. doi:https://doi.org/10.1007/s11661-002-0074-9

Lee S-H, Lee CH,Lim CY (2004) Mater Sci Forum 449–452:161

Cao WQ, Liu Q, Godfrey A, Hansen N (2002) Mater Sci Forum 408–412:721

Huang X, Tsuji N, Hansen N, Minamino Y (2003) Mater Sci Eng A 340:265

Kim Y-S, Lee T-O, Shin DH (2004) Mater Sci Forum 449–452:625

Tsuji N, Ito Y, Saito Y, Minamino Y (2002) Scr Mater 47:893

Tsuji N, Ito Y, Nakshima H, Yoshida F, Minamino Y (2002) Mater Sci Forum 396–402:423

Kamikawa N, Tsuji N, Huang X, Hansen N (2006) Acta Mater 54:3055

Kim H-W, Kang S-K, Tsuji N, Minamino Y (2005) Acta Mater 53:1737

Kim H-W, Kang S-K, Tsuji N, Minamino Y (2006) Mater Sci Forum 512:85

Jang YH, Kim SS, Han SZ, Lim CY, kim CJ, Goto M (2005) J Mater Sci 40:3527

Jang YH, Kim SS, Han SZ, Lim CY, Kim CJ, Goto M (2005) Scr Mater 52:21

Lee SH, Han SZ, Lim CY (2006) Key Eng Mater 317–318:239

Tsuji N, Okuno S, Matsuura T, Koizumi Y, Minamino Y (2003) Mater Sci Forum 426–432:2667

Tsuji N (2006) In: Altan BS (ed) Severe plastic deformation. Nova Science Publishers, pp 545–565

Vaidyanath LR, Nicholas MG, Milner DR (1959) Brit Weld J 6:13

Bay N (1986) Metal Constr 18:369

Kwan C, Wang Z, Kang S-B (2007) Mater Sci Eng A 480:148. doi:https://doi.org/10.1016/j.msea.2007.07.022C

Acknowledgements

The authors would like to acknowledge Dr. Suk-Bong Kang of The Korean Institute of Material Sciences for providing the samples used in this study. This project is funded by Natural Science and Engineering Research Council of Canada (NSERC).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kwan, C., Wang, Z. Microstructure evolution upon annealing of accumulative roll bonding (ARB) 1100 Al sheet materials: evolution of interface microstructures. J Mater Sci 43, 5045–5051 (2008). https://doi.org/10.1007/s10853-008-2614-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-2614-1