Abstract

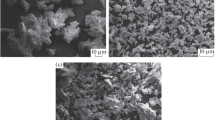

The copper matrix composites reinforced with SiC particulates (Cu/SiCp) were fabricated using a powder metallurgy method with the addition of 0.5, 1.5, 2.5, and 5 wt.% Fe. The microstructure and properties of the composites were studied. The results of this investigation revealed that the addition of Fe improved the interface bonding and mechanical and thermal physical properties of the composites. The fracture mechanism of the Cu/SiCp composites was found to change from interface de-bonding to matrix tearing due to the addition of Fe.

Similar content being viewed by others

References

Fabritrisiev SA, Zinkle SJ, Singh BN (1996) J Nucl Mater 233–237:127

Brendel A, Popescu C, Bolt H, Popescu C (2004) J Nucl Mater 329–333:804

You JH, Bolt H (2002) J Nucl Mater 305:14

Sefanik P, Sebo P (1993) J Mater Sci Lett 12:1083

Nikolopoulos P, Agathopoulos S (1992) J Mater Sci 27:139. doi:https://doi.org/10.1007/BF00553849

Yih P, Chung DDL (1995) Int J Powder Metall 31:335

Lee YF, Lee SL, Chung CL (1999) Powder Metall 42:147

Rui Z, Lian G (2004) Ceram Int 30:401

Pelleg J, Ganor M (1986) The Fe/SiC composite system, M.Sc.Thesis, Ben-Gurion University, Beer-Sheva

Pelleg J, Ruhr M, Ganor M (1996) Mater Sci Eng A212:139

Schiepers RCJ et al (1988) J Am Ceram Soc 71(6):214

Chou TC et al (1991) J Mater Res 6:796

Gotmam I, Gutmanas EY (1992) Acta Metall Mater 40:121

Weast RCJ, Astle MJ, Beyer WH (1985–1986) CRC handbook of chemistry and physics, 66th edn. CRC Press Inc., Roca Raton

Acknowledgement

The authors would like to thank Instrumental Analysis Center of SJTU for SEM observation and the financial support from National Natural Science Foundation of China under grant No. 50271043.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gan, K., Gu, M. & Mu, G. Effect of Fe on the properties of Cu/SiCp composite. J Mater Sci 43, 1318–1323 (2008). https://doi.org/10.1007/s10853-007-2294-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-2294-2